- Home

- /

- Wind Power Data Acquisition

Application of Cables in Wind Power Data Acquisition Systems

1. Scene Introduction

one. Application of wind power data acquisition system for offshore wind farms

In the vast sea far from land, offshore wind farms are gradually becoming an important source of clean energy. These wind farms usually contain dozens or even hundreds of wind turbines, distributed in the vast sea. Due to the complexity and variability of the offshore environment, cables need to withstand harsh conditions such as seawater erosion, strong winds and large waves. Our wind power data acquisition system cables use special anti-corrosion materials and sealing design to ensure long-term stable operation in the marine environment. At the same time, the cable’s weather-resistant performance also enables it to adapt to the changing climatic conditions at sea, ensuring the continuity and stability of data transmission.

2.Sition system for large-scale onshore wind farms

In the vast plains or mountainous areas, large onshore wind farms are also important application scenarios for cable solutions. These wind farms usually cover a wide area, the distribution of wind turbines is relatively decentralized. Our cables are designed to be flexible and easy to lay and install in complex terrain. At the same time, the cable’s high bandwidth and low attenuation characteristics ensure real-time and accurate data transmission between the WTGs and the monitoring center.

3.The application of wind power data acquisition system for wind farms in remote areas

In some remote areas, due to the limitation of terrain, climate and other factors, it is difficult to implement the traditional energy supply method. And wind power, as a clean and renewable form of energy, has unique advantages in these areas. However, the natural conditions in these regions are often harsh, placing higher demands on the performance and reliability of the cables.

Whether it is an offshore wind farm, a large onshore wind farm or a remote wind farm, TST CABLES wind power data acquisition system cable solutions can provide stable and reliable data transmission support. We will provide personalized solutions and services according to the needs and characteristics of different application scenarios to meet the diverse needs of customers.

2. The pain point analysis

In the application process of wind power data acquisition system, cables, as the medium of data transmission, face many challenges:

Harsh environment: wind farms are usually located in remote areas with complex and changing climatic conditions, and the cables need to withstand high temperature, low temperature, strong wind, salt spray and other harsh environments.

Electromagnetic interference: wind farms in the presence of a large number of electrical equipment, cable in the transmission of data is susceptible to electromagnetic interference, affecting the accuracy and stability of data.

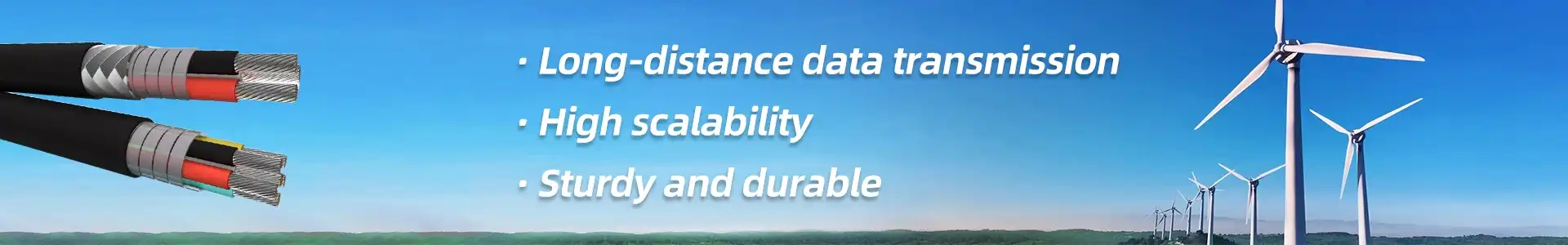

Long-distance transmission: wind farms cover a wide area, the cable needs to cover a large range, to achieve long-distance transmission of data.

3.The wind power data acquisition system on the cable requirements

For the special needs of wind power data acquisition system, the cable needs to meet the following requirements:

Strong weather resistance: able to maintain stable electrical performance in a variety of harsh climatic conditions.

Anti-electromagnetic interference: good shielding performance, effectively resist electromagnetic interference, to ensure the accurate transmission of data.

Low attenuation, high bandwidth: to meet the demand for high-speed and stable transmission of large amounts of data.

4. The certification standards

To ensure that the performance and quality of the cables meet the highest standards in the industry, TST CABLES products are fully compliant with the following international and domestic certification standards:

UL Certification: The Underwriters Laboratories of the United States of America conducts rigorous testing of the electrical and mechanical properties of the cable to ensure that it meets safety standards.

CE certification: A mark of conformity with the requirements of the European Union directives, indicating that the cable meets the requirements of the European Union’s regulations on safety, health, and environmental protection.

RoHS certification: A directive restricting the use of certain hazardous substances, ensuring that cables are environmentally friendly during production and use.

In addition, our cables meet industry-specific standards such as IEC 60332 (Standard for Flammability Performance of Cables) and EN 50264, GB/T 2423.1, GB/T 2423.2, IEC 60068-2-1, IEC 60068-2-2, EN 60068-2-1, EN 60068-2-2, etc. to ensure that the cables are safe and reliable in their applications. safety and reliability in the application.

In addition, the cables are subject to specific certifications for the wind power industry to ensure that they are adapted to the special operating environment of wind farms.

5.Cable Selection

According to the needs of wind power data acquisition system, TST CABLES recommends the following cable selection:

Low-smoke halogen-free flame-retardant cables: low-smoke halogen-free materials with excellent flame-retardant properties, reducing the risk of fire.

Shielded cable: Built-in shielding layer, effectively resist electromagnetic interference, to ensure stable data transmission.

Flexible cable: with good flexibility, easy to lay and install in the complex terrain of wind farms.

Selection parameters for reference (can be customized according to actual needs)

Rated voltage: 300V AC

Temperature range: -40°C to 90°C

Bending radius: 6D (D refers to the outer diameter of the cable)

Characteristic impedance: 1200+120 (0.75~3MHz)

Attenuation: <1.0dB/100m (1MHz)

<1.0dB/100m (2MHz)

Operating capacitance: ≤65pF/m (1.0MHz)

Grounding capacitance: <1.5pF/m (1.0MHz)

Transmission impedance: <20mΩ/m (20MHz)

Abrasion Resistant

Antioxidant

No deformation

6. Product Characteristics

The cable products in this solution have the following characteristics:

Excellent weatherproof performance: made of special materials, able to maintain stable electrical performance under extreme climatic conditions.

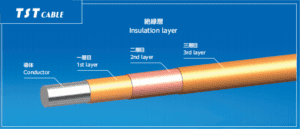

Strong shielding performance: built-in multi-layer shielding structure, effectively resist electromagnetic interference and ensure the accuracy of data transmission.

High bandwidth and low attenuation: adopting high-quality conductor and insulating materials to realize high-speed and stable data transmission.

Recommended Products

Wind power data acquisition system cables are tensile and wear-resistant and adaptable to harsh environments. They are an important part of the wind energy system and are responsible for transmitting data from various sensors and equipment such as anemometers, wind turbines, and power converters to the data acquisition and control system.

7.Technical Tests

To ensure the performance and quality of wind power data acquisition system cable products, TST CABLES has conducted a series of strict technical tests, including:

Weathering test: simulate the harsh climate conditions of wind farms to test the weathering performance of the cables.

Electromagnetic compatibility test: Tests the performance of cables in electromagnetic interference environments.

Electrical performance test: test the cable’s impedance, attenuation and other electrical parameters to verify its transmission performance.

TST CABLES wind power cable testing standards may also include some specific test items, such as oil resistance, low-temperature torsional performance. These tests are developed according to the actual use of the cable environment and specific needs to ensure that the cable in a variety of complex conditions can show good performance.

8. Cable laying installation and commissioning

In the process of cable laying and installation, TST CABLES will develop a reasonable laying program according to the actual situation of the wind farm to ensure the safe and reliable operation of the cable. At the same time, provide professional commissioning guidance to assist customers to complete the cable and data acquisition system connection and commissioning work to ensure the normal operation of the system.

9. After-sales maintenance & technical support

TST CABLES provides comprehensive after-sales maintenance and technical support services, including regular inspection, troubleshooting, repair and replacement of wind power data acquisition system cables. Our professional team will provide technical support and solutions for customers at any time to ensure the stable operation of wind power data acquisition system cables and customer satisfaction.

10.TST CABLES wind power data acquisition system Cable Cases

TST CABLES has successfully applied the wind power data acquisition system cables in this solution in large-scale wind power projects in many coastal cities in China. After long-term operation verification, the cable shows excellent weather resistance, anti-magnetic interference ability and data transmission stability. The wind farm is located in the sea far from the land, the environment is complex and harsh, the performance and quality of the cable put forward very high requirements.

In this wind power project, the application of wind power data acquisition system cable has achieved remarkable results. It not only improves the data collection efficiency and accuracy of the wind farm, but also provides great convenience for the operation and maintenance management of the wind farm. At the same time, the stability and reliability of the cable has been fully verified, providing a strong guarantee for the long-term stable operation of the wind farm.

Other solutions for cables in wind power applications.

WHY CHOOSE TST CABLES

10 years of experience

Specializing in the production of railway cables for 10 years

Engineer-to-engineer one-on-one support

Engineers provide one-on-one service to assist with product selection and problem-solving

Customization according to requirements

With a strong R&D team, we support customized cables based on specific needs

Quality certification

Stringent adherence to industry standards, complete certification

Fully testing facilities

Various tests based on customer requirements

10,000 ㎡ factory

Welcome to visit our factory face to face

RELATER NEWS

Also available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese