With the acceleration of urbanization, the development of underground space resources has received more and more attention. As an important part of urban infrastructure construction, the waterproof and plugging technology of underground projects has become the key to ensuring project safety and extending service life.

Due to the increasingly complex hydrogeological and environmental conditions in which underground projects are located, they have been eroded by groundwater and moisture in the soil for a long time, which is prone to structural damage, leakage and other problems, seriously affecting the use function and structural durability of underground projects.

It is very important to plug the holes through the walls of pipelines in underground projects. First of all, plugging the holes can effectively prevent water leakage. The environment of underground projects is complex. If they are not plugged, groundwater, rainwater, etc. can easily penetrate through the holes, which will not only destroy the structural stability of underground projects, but also cause damage to electrical equipment and affect the normal operation of the entire project. For example, if the cable pipeline is not plugged, when the groundwater level rises, the water will soak the cable, causing serious consequences such as leakage and power outage.

Secondly, plugging can prevent the breeding of harmful organisms. The underground space is dark and humid, and it is easy to become a habitat for small animals such as mice and insects. These harmful organisms may gnaw on cables, damage pipelines, and cause power supply accidents or other safety hazards. At the same time, their activities may also bring bacteria and viruses, posing a threat to the environmental sanitation of underground projects.

In addition, good sealing can also keep the internal environment of underground projects clean and dry. This is crucial for subsequent construction and equipment installation. If there is water accumulation in the underground well or it is invaded by small animals, it will cause great trouble to the laying of cables and other work, increasing construction costs and time.

Traditional plugging project

Traditional sealing materials mainly include cement sandstone, waterproof glue, waterproof coating, plugging materials, etc. These materials play a good sealing role in the construction process. However, as the years of use gradually expose some disadvantages, cracks, aging, and cracking may occur due to uneven vibration, shrinkage, temperature, humidity, etc., resulting in loose sealing and affecting the overall project safety;

In addition, the construction process of traditional sealing materials is relatively complicated, requiring on-site mixing, smearing, filling and other operations, which takes a long time; during subsequent renovation or maintenance, it is difficult to remove and re-seal, and the service life and long-term economic value are not high.

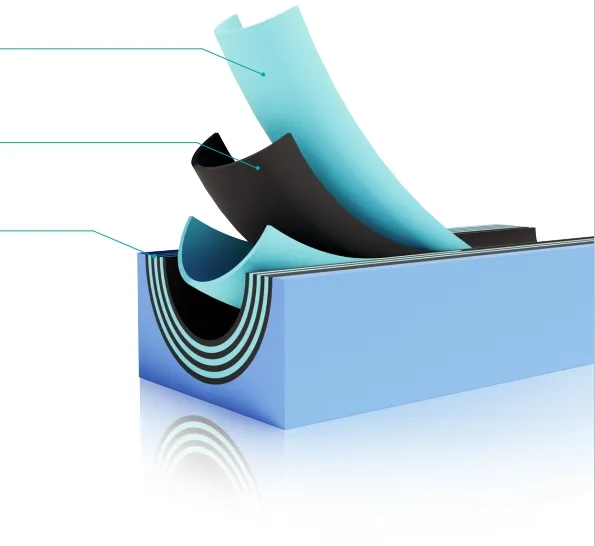

Compared with the many disadvantages of traditional plugging methods, modular sealing uses high-quality materials such as polymer materials, has good weather resistance, corrosion resistance and anti-aging performance, stable and reliable performance, and is more suitable for waterproof plugging of underground projects.

TST CABLES sealed module fireproof plugging project

(I) Comply with international standards and provide all-round protection

The modular sealing system has been tested and certified by authoritative organizations, and can provide all-round protection for cable trenches in underground projects, such as fireproofing, watertightness, airtightness, corrosion resistance, and rodent resistance, which are certified by authoritative organizations. For example, in underground projects, the cable and pipeline penetration sealing system uses high-performance materials such as EPDM rubber and austenitic stainless steel, which are essentially non-polar, and have good watertightness, airtightness, fire resistance, aging resistance, electrical insulation, and chemical resistance. This enables cables and pipelines in underground projects to operate stably in complex environments and extend their service life.

(II) Scientific design is easy to install and improves construction efficiency

The standard variable diameter sealing module of TST CABLES and pipeline penetration systems enables construction personnel to combine and design products like building blocks, which is extremely flexible. This design supports lossless addition or replacement of pipes/cables, meeting the needs of future cable pipe modification and expansion, and future upgrades will not increase costs. In underground projects, construction space is often limited, and traditional sealing methods are difficult to construct. The modular sealing system reduces the construction difficulty. One opening can accommodate dozens of cables and pipes of different diameters, which can help construction workers reduce installation time and reduce the weight of installation components, saving users up to 70% of installation time. The installation process is standardized and the appearance is neat and beautiful, which greatly improves construction efficiency.

(III) Replacement of traditional sealing methods, with significant advantages

Compared with traditional sealing methods, the application of modular sealing systems in underground projects has significant advantages. Traditional sealing methods have serious deficiencies in air tightness, smoke tightness, environmental protection performance, service life, explosion resistance, explosion-proof performance, moisture resistance, rat bite resistance, appearance, etc. The modular sealing system has good fire resistance, waterproofness, corrosion resistance, long life and other characteristics, which are more advantageous and cost-effective in application. For example, in civil air defense projects of underground projects, the modular pipe hole sealing device adopts a single-side plugging structure, which has waterproof and fireproof functions; it meets the needs of pipelines with various apertures; the structure is reliable, flexible in matching, easy to install, convenient in design, easy to disassemble, and reusable.

TST CABLES is a domestic brand that focuses on providing modular cable and pipe penetration sealing systems for users in various industries. It can provide all solutions for cable and pipe penetration for customers in various industries around the world. For many years, it has continued to focus on the upgrade and transformation of cable and pipe modular sealing solutions. In the future, TST CABLES will rely on high-quality products and considerate and comprehensive services to ensure the safety of underground projects.

Also available in:

Arabic

English

Japanese

Russian

Portuguese (Brazil)