- Home

- /

- Vehicle monitoring system

Application of Cables in Vehicle Safety Monitoring Systems

1.Scene Introduction

With the rapid development of rail transportation technology, the vehicle safety monitoring system plays an increasingly important role in ensuring the safety of train operation and enhancing operational efficiency. The system realizes all-round monitoring of vehicle status, operating environment and passenger safety by integrating various sensors, cameras and communication devices. As the link connecting each monitoring component, the safety and stability of cables are directly related to the normal operation of the whole monitoring system. Therefore, a professional cable solution for rail transit vehicle safety monitoring system has become an urgent need in the industry.

2.The pain point analysis

In the existing rail transit vehicle safety monitoring system, there are the following pain points in the cable:

Unstable signal transmission: Due to the complex and changing environment of train operation, cables are susceptible to electromagnetic interference, vibration and other factors when transmitting monitoring signals, resulting in signal distortion or interruption.

Insufficient reliability: as a key component of the monitoring system, the quality and reliability of the cable directly affects the stability and safety of the entire system. However, some of the cable products on the market have uneven quality, easy to aging and other issues, bringing potential hazards to vehicle safety.

Installation and maintenance difficulties: due to the limited space inside the train, cable laying and installation is more difficult. At the same time, the maintenance and management of the cable also has certain challenges, the need for professional technical support and regular inspection.

3. The vehicle safety monitoring system on the cable requirements

For the characteristics of vehicle safety monitoring system, the cable needs to meet the following requirements:

Excellent transmission performance: to ensure stable and accurate transmission of monitoring signals to avoid signal distortion or interruption.

High reliability: the cable should have excellent durability and anti-aging properties, and can work stably for a long time in various harsh environments.

Good environmental adaptability: the cable should be able to adapt to high temperature, low temperature, humidity, vibration and other complex environments to ensure stable operation of the system.

4.Certification Standards

To ensure the safety and compliance of the cable, the cable products in the vehicle safety monitoring system solution fully comply with the following certification standards:

CE certification: a mark of compliance with the requirements of the European Union Directive, indicating that the cable meets the requirements of the European Union’s safety, health, environmental protection and other regulations.

RoHS certification: A directive restricting the use of certain hazardous substances, ensuring that the cables are environmentally friendly during production and use.

In addition, our cables meet specific standards for the rail transportation industry, such as IEC 60332 (standard for combustion performance of cables) and EN 50264 (standard for cables for rail transportation), GB/T 2423.1, GB/T 2423.2, IEC 60068-2-1, IEC 60068-2-2, EN 60068-2-1, EN 60068-2-2, etc. to ensure that the cables can be used in the rail transportation industry. 2-2, etc. to ensure the safety and reliability of cables in rail transportation applications.

5. Cable Selection

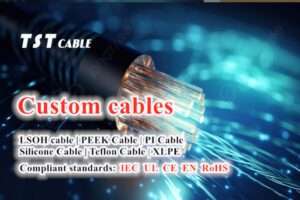

We recommend the following cable types for the needs of vehicle safety monitoring system:

Low-smoke halogen-free flame-retardant cables: low-smoke, halogen-free, flame-retardant and other characteristics, in the event of a fire can reduce the production of smoke and toxic gases to improve the safety of evacuation.

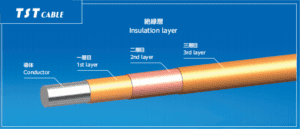

Shielded cable: adopting multiple shielding structure, effectively suppressing electromagnetic interference and ensuring stable transmission of monitoring signals.

Flexible cable: It has good flexibility and bending performance, adapting to the complex wiring environment inside the train.

Selection parameters for reference (can be customized according to actual needs)

Rated voltage: 300V AC

Temperature range: -40°C to 90°C

Bending radius: 6D (D refers to the outer diameter of the cable)

Characteristic impedance: 100Ω+15Ω (100MHz)

Insulation voltage: DC 1000V/1min

Tinned copper

Resistant to oxidation

High conductivity

Wear-resistant

Antioxidant

No deformation

6.Product characteristics

The cable products in this solution have the following characteristics:

Excellent transmission performance: adopting high-purity conductor and high-quality insulation materials to ensure stable and accurate transmission of monitoring signals.

High reliability: the cable has a sturdy structure, excellent anti-aging performance, and can work stably for a long time in various harsh environments.

Good environmental adaptability: the cable has good resistance to high temperature, low temperature, anti-vibration and other properties, adapting to the various environments of train operation.

EMI shielding: to ensure accurate data transmission and prevent interference, the cable should have effective electromagnetic interference (EMI) shielding.

Recommended Products

The vehicle safety monitoring cable has a rated voltage of 300V, good insulation performance and strong anti-interference ability. It plays a vital role in transmitting data and signals from various safety sensors to the monitoring system in the vehicle.

7.Technical Tests

To ensure the performance and quality of cable products, TST CABLES conducts a series of rigorous technical tests, including:

Electrical Performance Test: Test the electrical parameters such as resistance, insulation resistance, capacitance of the cable to ensure that it meets the design requirements.

Mechanical performance test: testing the cable’s tensile strength, bending performance, abrasion resistance and other mechanical properties to ensure its stability during train operation.

Environmental adaptability test: the cable is placed in high temperature, low temperature, humidity and other harsh environments for a long time to verify its environmental adaptability.

Electromagnetic compatibility (EMC) test: test the signal transmission performance of the cable in the electromagnetic interference environment to ensure that it has good anti-interference (EMI) shielding capability. To ensure that the vehicle safety monitoring system cable in the complex electromagnetic environment work properly.

8. Cable laying installation and commissioning

In the vehicle safety monitoring system cable laying and installation process, TST CABLES will be based on the structure of the vehicle and the layout of the monitoring system to develop a reasonable cable routing program. Meanwhile, TST CABLES will provide professional commissioning guidance to assist customers to complete the connection and commissioning of the cable and monitoring system to ensure the normal operation of the system.

9. After-sales maintenance & technical support

TST CABLES provides 7*24h comprehensive after-sales maintenance and technical support services, including regular inspection of cables vehicle safety monitoring system cables, troubleshooting, repair and replacement. Our professional team will provide customers with technical support and solutions at any time to ensure the stable operation of vehicle safety monitoring system cable and customer satisfaction.

10. Actual Cases

TST CABLES has provided high performance data transmission cables for vehicle safety monitoring system in the subway projects of many large cities in China.TST CABLES EN50264 series and EN50306 series cables for rail transportation have obtained CRCC certification. At present, more than 500000 cables have been installed in more than 3500 high-speed rail coaches, with a running mileage of more than 6,000,000 kilometers. After long-term actual operation test, the cables have outstanding performance. The data shows that TST CABLES’ cables have reached thousands of Mbps in data transmission rate stably without any failure during the whole project operation. In addition, the cable’s abrasion and corrosion resistance was also highly evaluated by the customer. This success story fully proves the superiority and reliability of TST CABLES’ cable solutions in the application of railroad vehicle safety monitoring system.

In summary, this cable solution for rail vehicle safety monitoring system has excellent product performance, strict quality control and comprehensive technical support, TST CABLES will continue to be committed to provide customers with better products and services to promote the continuous development and safe operation of the rail transportation industry.

Other solutions for cables in railway applications.

WHY CHOOSE TST

10 years of experience

Specializing in the production of railway cables for 10 years

Engineer-to-engineer one-on-one support

Engineers provide one-on-one service to assist with product selection and problem-solving

Customization according to requirements

With a strong R&D team, we support customized cables based on specific needs

Quality certification

Stringent adherence to industry standards, complete certification

Fully testing facilities

Various tests based on customer requirements

10,000 ㎡ factory

Welcome to visit our factory face to face

RELATER NEWS

Also available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese

Portuguese (Brazil)