UL 1479 and UL 2079 are standards for through-wall firestop systems issued by Underwriters Laboratories (UL), but they target different types of fire conditions and applications. TST CABLES will take you to understand the difference between these two standards.

UL 1479 (Fire Tests of Through-Penetration Firestop Systems)

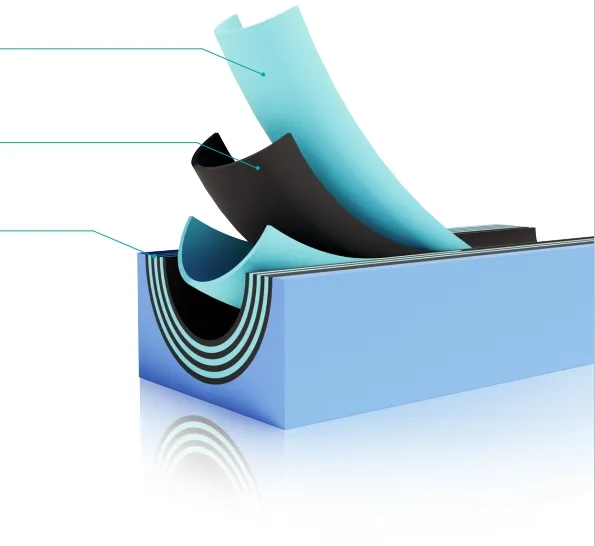

This standard focuses on fire-stopping systems for pipes, cables, metal casings, etc. that penetrate walls or floors. It tests whether these systems can effectively prevent the spread of flames and smoke and maintain structural integrity when encountering a fire.

Testing includes exposure to a specified fire curve that simulates the temperature rise of a fire that may occur in a building. In addition, a water spray test is required to verify the performance of the system after the fire sprinkler system is activated.

Once a system has passed the test, it will be rated for a certain time (e.g., 1 hour, 2 hours, 3 hours, etc.) based on its fire resistance, which means that the system can maintain fire resistance for a specified time.

UL 2079 (Tests for Fire Resistance of Building Joint Systems)

This standard is designed for building joint systems, such as fireproofing materials or components used in joints between walls and between walls and floors. These systems are used to prevent the spread of flames through non-penetrating linear openings in buildings.

It also involves fire resistance testing, but focuses more on the performance of joints when they expand or contract due to heat, and their ability to maintain their fire resistance function when displacement occurs (such as structural movement caused by seismic activity).

Similarly, the system will be rated for a corresponding time based on its fire resistance performance.

UL 1479 is mainly applicable to evaluating the performance of fire blocking systems for penetrating openings, while UL 2079 is for fire protection solutions at joints in building structures. Both are intended to ensure the safety of buildings in the event of a fire, but their application scenarios and technical requirements are different.

UL 1479 and UL 2079 each provide detailed test conditions for different types of firestop systems to ensure that they provide the necessary protection in a fire. Here is an overview of the test conditions for both standards:

UL 1479 (Fire Tests of Through-Penetration Firestop Systems)

Test Conditions:

Flame Exposure: The seal is exposed to a simulated fire environment under a specified temperature-time curve. This curve usually follows the standard temperature rise curve in ISO 834 or ASTM E119.

Water Spray Test: After a simulated fire, the sample is sprayed with water using a fire hose to evaluate its performance when it is subjected to water spray fire extinguishing.

Heat Resistance: The heat resistance of the system is evaluated based on whether flames occur on the unexposed side and the heat transfer.

Air and Water Tightness (Optional): The air and water leakage tests determine the air tightness and water tightness of the system under a specific air pressure difference.

Rating:

F-Class: Based on the occurrence of flames on the unexposed side and the performance of the water gun spray.

T-Rating: Based on temperature rise, occurrence of fire on the unexposed side, and water jet performance.

For some systems, an L-Rating is also established, which is a rating for air leakage, and a W-Rating is a rating for water resistance.

UL 2079 (Tests for Fire Resistance of Building Joint Systems)

Test Conditions:

Fire Exposure: The joint system is also exposed to a simulated fire environment under a specified temperature-time curve.

Structural Movement: The joint system is subjected to a series of cyclic movements to simulate the dynamic behavior of the actual application, taking into account possible movement of the building (such as seismic activity).

Load Carrying: If the joint is load-bearing, the design live load is applied.

Hose Stream Test: For testing of wall-to-wall and wall-head joint systems, a specified standard hose stream is applied after the fire test.

Air Tightness (optional): Measures the air leakage rate through the joint system, which is caused by a specific air pressure difference applied to the surface of the joint system.

Water Tightness (optional): Tests the ability of the joint system to resist water penetration under a three-foot head of water pressure.

Ratings:

L-Rating: Based on the amount of air leakage through the test sample.

AW Rating: Based on the water resistance of the test sample.

Both UL 1479 and UL 2079 are designed to evaluate the fire resistance of fire protection systems and provide a standardized rating system for products so that architects, engineers and other professionals can use these ratings to select products that are appropriate for their project needs. Each test is designed to simulate real-world conditions and has very strict requirements to ensure the reliability and effectiveness of the fire protection system.

Also available in:

English