UL cable characteristics and applications

UL cable refers to cables certified by Underwriters Laboratories (UL). UL is an independent third-party certification body that specializes in safety testing and certification of various products. UL certification is one of the most widely recognized safety standards in the world, ensuring that cables meet strict safety specifications during design, manufacturing and use.

Wires and cables in a broad sense are also referred to as cables. Cables in a narrow sense refer to insulated cables. It can be defined as: a collection of the following parts, one or more insulated cores, and their respective coatings, total protective layers and outer sheaths. Cables may also have additional uninsulated conductors.

Wire and cable products are divided into the following five categories according to their uses:

1. Bare wires 2. Winding wires 3. Power cables 4. Communication cables and communication optical cables 5. Wires and cables for electrical equipment

Main features of UL cables

1. Safety: UL cables undergo rigorous safety tests to ensure that they will not cause safety hazards such as fire or electric shock under normal use conditions.

2. Quality assurance: UL-certified cables meet high standards in all aspects such as material selection, production process and finished product inspection, ensuring product reliability and durability.

3. Clear identification: UL cables have clear identification indicating their certification type and scope of application, which is convenient for users to identify and choose.

4. Diverse certification standards: UL has formulated a variety of certification standards for different types of cables, such as UL 1007, UL 1015, etc., which are suitable for different applications.

UL cable application areas

UL cables are widely used in various occasions, including but not limited to:

· Household appliances: internal wiring of appliances such as washing machines, air conditioners, refrigerators, etc.

· Industrial equipment: electrical connections of equipment such as motors, control panels, sensors, etc.

· Building wiring: power wiring such as lighting and sockets inside buildings.

· Automotive industry: electrical connections inside cars, such as wiring in the engine compartment.

UL cable certification standards

Common UL cable certification standards include:

· UL 1007: Applicable to single-core insulated wires with a rated voltage of 300V.

· UL 1015: Applicable to single-core insulated wires with a rated voltage of 600V.

·UL 1581: Covers the flame retardant performance test standards for cables.

·UL 44: Involves the heat resistance and mechanical strength tests of cables.

Applications and models of various UL cables

1. UL equipment internal wires

1. Application: Used for internal wiring of automotive industry, mechanical equipment, computers, household appliances, electronic and electrical equipment.

2. Main products and models

⑴ Heat-resistant PVC wire: UL1007 UL1015 UL1032 UL1095

⑵ Semi-rigid PVC wire: UL1061

⑶ Irradiated cross-linked PVC wire: UL1571 UL1685

⑷ Heat-resistant PVC double-insulated wire: UL1430 UL1431 UL1681 UL1617

⑸ Radiation cross-linked PVC double-insulated wire: UL1672

⑹ Flame-retardant cross-linked polyethylene wire: UL1505

⑺ Radiation cross-linked flame-retardant PE wire: UL3265 UL3266 UL3271 UL3343 UL3398

II. UL shielded wire

1. Application: Using unique and exquisite winding and braiding technology, high-performance, anti-signal interference shielded wires are produced, mainly used for internal wiring of audio, video recorders, monitoring equipment, and electronic equipment.

2. Main products and models

⑴ Heat-resistant PVC shielded wire:

UL1185 UL1533 UL2127 UL2128 UL2129 UL2405 UL2265 UL2482 UL2483

⑵ Semi-rigid PVC shielded wire: UL2547

III. UL interface cable

1. Application: Applicable to internal wiring of electronic equipment such as computers, peripherals, office equipment, etc. USB cable realizes efficient signal transmission of office equipment such as computers and printers.

2. Main products and models

PVC insulated cable: UL2464

IV. UL wiring components

1. Application: Bending resistance, space saving, high-speed transmission, applied to internal wiring of digital home appliances and computers.

2. Main products and models

UL2468 UL2651 UL20080

V. UL irradiated cross-linked wire

1. Application: Mainly used for automotive electronic components, motors, lighting equipment and air conditioning equipment, etc.

2. Main products and models: UL1430 UL1571 UL1685 UL3321

VI. UL low-smoke halogen-free wire

1. Application: PVC wire contains halogen elements, which release a large amount of toxic smoke and corrosive gases when burned, destroying nature and endangering human life safety. For this reason, low-smoke halogen-free wires are widely used in subways, tunnels, ships and vehicles, as well as important high-rise buildings and other places and important facilities with relatively high safety requirements.

2. Main products and models: UL3321

Seventh, UL Teflon wire

1. Application: Fluoroplastic polymer materials (PFA, FEP, ETFE), the use of wire insulation layer with higher operating temperature, temperature resistance can reach 260/200 and 150, used in high temperature working environment, such as household appliances, lighting fixtures, electronic equipment, temperature sensors, gas appliances, microwave ovens, etc.

2. Main products and models

UL10362 UL1901 FEP wire UL1330 UL1331 UL1332 UL1333 PFA wire (250 degrees) UL1726 UL1727

Eighth, UL silicone wire

1. Application: Silicone wire is divided into non-braided and braided silicone wire, the conductor material is made of high-purity tinned or silver-plated copper wire, the outer sheath is made of silicone rubber material, with good acid, alkali and fungus resistance, resistant to hot and humid environment and high oil. It can be used in an environment of -60 degrees to below 200 degrees. It is mainly used in lighting fixtures, household appliances, electric heating appliances, digital appliances, motor leads and computer internal wiring.

IX. TPE wire

1. Use: TPE is the abbreviation of thermoplastic elastomer. It is a multifunctional material that exhibits rubber elasticity at room temperature and can be plasticized at high temperature. It has both the elasticity of rubber and the melt fluidity and reusability of thermoplastics. It is mainly used in power cords, plugs, plug wires, 1394 wires, USB wires, game console wires, audio headphone wires, speaker wires, mobile phone charging wires, headphone wires and other low-power electronic wires.

X. Computer case power supply dedicated wiring

1. Use: It uses high-purity environmentally friendly OFC oxygen-free pure copper, high-quality terminals and temperature resistance and anti-aging to provide high transmission power, low energy consumption energy-saving wiring for PC power supplies, and provide safe and efficient energy transmission for various components of the computer, so that core components such as CPU and motherboard can do their best.

2. Main products and models

L+L 20+4P SATA+SATA L+L+S 4P

XI. Wiring of computer peripherals

1. USB data transmission line provides accurate, timely and efficient data transmission for computer peripherals such as mouse, keyboard, copier, printer and scanner.

2. Main products and models: UL2464

XII. Wiring of general lighting fixtures

1. Purpose: Using high-purity OFC oxygen-free copper, it provides efficient, safe and stable power transmission for lighting electrical products, creating an efficient, comfortable, safe, economical and beneficial lighting environment.

2. Main products and models: SPT-1 SPT-2

XIII. Wiring of LED lighting lamps

1. Purpose: LED light source is considered to be a new type of light source, with the advantages of using low-voltage power supply, low energy consumption, strong applicability, high stability, short response time, no pollution to the environment, and multi-color luminescence.

14. Electrical plug power cord:

The power plug power cord complies with 3C certification, European VDE and American UL certification.

Cable classification model knowledge

Cable model types and uses

1. Bare wire:

L-aluminum wire T-copper wire G-steel wire

2. Power cable:

V-plastic cable X-rubber cable

3. Communication cable:

H-communication cable HJ-bureau cable HP-wiring cable HU-mining cable

4. Wires and cables for electrical equipment:

B-insulated wire DJ-electronic computer K-control cable R-soft wire Y-mobile cable ZR-flame retardant

Main technical parameters

1. Usage characteristics of polyvinyl chloride insulated wires

Rated voltage U0/U is 450V/750V or 300V/500V.

Among them, U0 is the rated power frequency voltage between the conductor and the shield or metal sheath for cable design;

U is the rated power frequency voltage between the conductors for cable design

2. General rubber sheathed flexible cable is suitable for AC rated voltage up to 450V and DC rated voltage up to 700V as power transmission line for household appliances, power tools and various mobile electrical equipment.

YQ light rubber sheathed flexible cable. Connects light mobile electrical equipment with AC voltage of 250V and below.

YQW connects light mobile electrical equipment with AC voltage of 250V and below, with weather resistance and certain oil resistance

YZ medium rubber sheathed flexible cable. Connects various mobile electrical equipment with AC voltage of 500V and below

YZW connects various mobile electrical equipment with AC voltage of 500V and below, with weather resistance and certain oil resistance

YC heavy rubber sheathed flexible cable. Connecting various mobile electrical equipment with AC voltage of 500V and below, it can withstand large mechanical external forces

YCW Connecting various mobile electrical equipment with AC voltage of 500V and below, it can withstand large mechanical external forces

Note: W in the model indicates outdoor type.

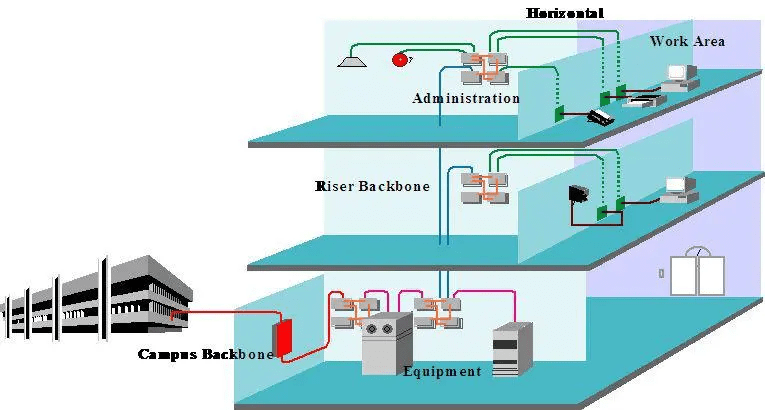

Wire and cable specification model table The cable model consists of eight parts: 1. Usage code-not marked as power cable, k is control cable, p is signal cable; 2. Insulation code-z oil-impregnated paper, x rubber, v polyvinyl chloride, yj cross-linked polyethylene 3. Conductor material code-not marked as copper, l is aluminum; 4. Inner sheath code-q lead sheath, l aluminum sheath, h rubber sheath, v polyvinyl chloride sheath 5. Derivative code-d non-drip, p dry insulation; 6. Outer sheath code 7. Special product code-th wet tropical, ta dry tropical; 8. Rated voltage-single Position kv

List of wire and cable specifications and models Questions about cable models

Sywv (y), sykv cable TV, broadband network special cable structure: (coaxial cable) single oxygen-free round copper wire + physical foamed polyethylene (insulation) + (tin wire + aluminum) + polyvinyl chloride (polyethylene)

2. Signal control cable (rvv sheathed wire, rvvp shielded wire) is suitable for building intercom, anti-theft alarm, fire protection, automatic meter reading and other projects

3. rvvp copper core polyvinyl chloride insulation shielded polyvinyl chloride sheathed soft cable Cable voltage 300v/300v2-24 core

Application: Instruments, meters, intercom, monitoring, control installation

4. KVVP: PVC sheathed braided shielded cable Application: Signal transmission, control, measurement of electrical appliances, meters, and power distribution devices

5. RVV (227IEC52/53) PVC insulated soft cable Application: Household appliances, small power tools, instruments and power lighting

6. RV PVC insulated cable

7. RVS, RVB are suitable for household appliances, Cables for connecting small electric tools, instruments, meters and power lighting

8. Uses of BV and BVR PVC insulated cables: Suitable for fixed wiring of electrical instruments and power lighting

9. Uses of KVV PVC insulated control cables: Signal transmission, control and measurement of electrical appliances, meters and power distribution devices

RVV and KVV RVVP and KVVP

Differences in the specification table of wires and cables: The wires used in RVV and RVVP are soft wires composed of multiple strands of fine copper wires, that is, RV wires.

The wires used in KVV and KVVP are hard wires composed of single strands of thick copper wires, that is, BV wires.

Differences between AVVR and RVVP: The things are the same, but the name of the internal cross-section less than 0.75 square millimeters is AVVR, and the name greater than or equal to 0.75 square millimeters is RVVP.

Differences between SYV and SYWV: SYV is a video transmission line insulated with polyethylene. SYWV is a radio frequency transmission line with physical foam insulation. Used for cable television.

The difference between RVS and RVV2 cores: RVS is a double-core RV wire twisted together, without an outer sheath, and is used for broadcast connection.

The RVV2 core wire is laid straight into a cable with an outer sheath, and is used for power supply, control signals, etc.

Specifications and models of wires and cables R-soft cable (wire) for connection, soft structure. V-insulated polyvinyl chloride. V-polyvinyl chloride insulation V-polyvinyl chloride sheath B-flat (flat). S-twisted pair. A-tinned or silver-plated. F-high temperature resistant P-braided shield P2-copper tape shield P22-steel tape armor Y-prefabricated, generally omitted, or polyolefin sheath FD-product category code, refers to branch cable. The standards of the Ministry of Construction to be promulgated are represented by fz, which are essentially the same!

yj—cross-linked polyethylene insulation

v—polyvinyl chloride insulation or sheath

zr—flame retardant

nh—fire resistant

wdz—halogen-free low-smoke flame retardant

wdn—halogen-free low-smoke fire resistant

If you have customized UL cables, Teflon wires, armored wires, industrial cables, power cables, control cables and other products, and need further technical support or cable solutions, you can send an email to the professional cable engineer of TST Cable Manufacturer at any time (email: lixiangchao@testeck.com, please state your country, your industry, and your needs in the email, and we can also provide you with free samples)

Also available in:

English