High-temperature cables are cables capable of safely and stably transmitting power signals and data signals in high-temperature environments (usually above 200°C, with some materials even up to 1300°C or higher).

They are widely used in fields that require high temperature environment for power transmission and signal control, such as industrial production, petrochemical industry, nuclear power plant, automobile manufacturing, aerospace and so on.

Execution standard: EN certification, CQC certification, EU CE certification, American UL certification, etc.

Product characteristics:

- 1. Rated voltage: 450/750V

- 2. Operating temperature: -60 ~ +200 ℃ (some materials customized special cable maximum touch temperature up to 1300 ℃)

- 3. Conductor: Stranded tinned copper wire, nickel-plated copper wire, etc.

- 4. Color: red/yellow/orchid/white/black/yellow-green/brown/green, etc.

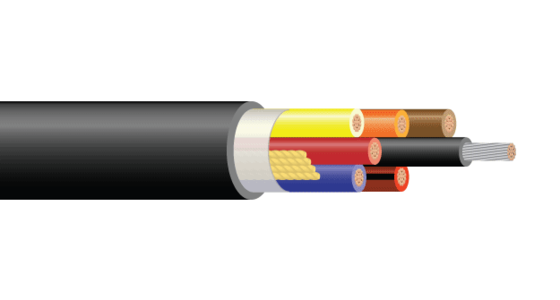

Structure parameters

- Conductor material: multi-strand soft copper conductor;

- Insulation material: fluoroplastic insulation, temperature range -60-260 degrees;

- Filling material: glass fiber;

- Sheath material: fluorine plastic sheath, temperature range -60-260 degrees

Technical Parameters

| Number of cores x section(mm) | Conductor structure Number of roots/wire diameter(mm) | Insulation thickness(mm) | Insulation Outer Diameter (mm) | Sheath thickness (mm) | Average Outer Diameter(mm) | |

|---|---|---|---|---|---|---|

| 2 × 4 | 56/0.30 | 0.70 | 4.10 | 1.40 | 11.0 | 5.09 |

| 3 × 4 | 56/0.30 | 0.70 | 4.10 | 1.60 | 12.0 | 5.09 |

| 4 × 4 | 56/0.30 | 0.70 | 4.10 | 1.80 | 13.5 | 5.09 |

| 5 × 4 | 56/0.30 | 0.70 | 4.10 | 1.80 | 14.6 | 5.09 |

| 6 × 4 | 56/0.30 | 0.70 | 4.10 | 1.80 | 16.0 | 5.09 |

| 7 × 4 | 56/0.30 | 0.70 | 4.10 | 1.80 | 16.0 | 5.09 |

| 10 × 4 | 56/0.30 | 0.70 | 4.10 | 2.20 | 20.0 | 5.09 |

| 12 × 4 | 56/0.30 | 0.70 | 4.10 | 2.40 | 22.0 | 5.09 |

| 2 × 6 | 84/0.30 | 0.70 | 4.90 | 1.60 | 13.0 | 3.39 |

| 3 × 6 | 84/0.30 | 0.70 | 4.90 | 1.60 | 13.8 | 3.39 |

| 4 × 6 | 84/0.30 | 0.70 | 4.90 | 1.80 | 15.4 | 3.39 |

| 5 × 6 | 84/0.30 | 0.70 | 4.90 | 1.80 | 16.8 | 3.39 |

| 6 × 6 | 84/0.30 | 0.70 | 4.90 | 2.00 | 18.8 | 3.39 |

| 7 × 6 | 84/0.30 | 0.70 | 4.90 | 2.00 | 18.8 | 3.39 |

| 10 × 6 | 84/0.30 | 0.70 | 4.90 | 2.20 | 23.4 | 3.39 |

| 2 × 10 | 84/0.40 | 1.0 | 6.60 | 1.80 | 17.0 | 1.95 |

| 3 × 10 | 84/0.40 | 1.0 | 6.60 | 1.80 | 18.0 | 1.95 |

| 4 × 10 | 84/0.40 | 1.0 | 6.60 | 2.00 | 20.0 | 1.95 |

| 5 × 10 | 84/0.40 | 1.0 | 6.60 | 2.40 | 22.8 | 1.95 |

| 2 × 16 | 126/0.40 | 1.2 | 8.40 | 2.50 | 21.8 | 1.24 |

| 3 × 16 | 126/0.40 | 1.2 | 8.40 | 2.60 | 23.2 | 1.24 |

| 4 × 16 | 126/0.40 | 1.2 | 8.40 | 2.60 | 25.6 | 1.24 |

| 5 × 16 | 126/0.40 | 1.2 | 8.40 | 2.80 | 28.2 | 1.24 |

| 2 × 25 | 196/0.40 | 1.30 | 10.10 | 2.6 | 25.4 | 0.795 |

| 3 × 25 | 196/0.40 | 1.30 | 10.10 | 2.6 | 27.0 | 0.795 |

| 4 × 25 | 196/0.40 | 1.30 | 10.10 | 2.6 | 29.6 | 0.795 |

| 5 × 25 | 196/0.40 | 1.30 | 10.10 | 2.6 | 32.80 | 0.795 |

| 2 × 35 | 494/0.30 | 1.4 | 11.5 | 2.4 | 28.0 | 0.565 |

| 3 × 35 | 494/0.30 | 1.4 | 11.5 | 2.6 | 30.0 | 0.565 |

| 4 × 35 | 494/0.30 | 1.4 | 11.5 | 2.6 | 33.0 | 0.565 |

| 3 × 50 | 396/0.40 | 1.6 | 14.0 | 2.8 | 36.0 | 0.393 |

| 4 × 50 | 396/0.40 | 1.6 | 14.0 | 2.8 | 39.6 | 0.393 |

| 3 × 70 | 551/0.40 | 1.6 | 15.6 | 3.0 | 10.0 | 0.277 |

| 3 × 95 | 760/0.40 | 1.8 | 18.2 | 3.2 | 45.8 | 0.210 |

| 3 × 120 | 608/0.50 | 2.0 | 20.0 | 3.6 | 50.6 | 0.164 |

| 3 × 150 | 760/0.50 | 2.2 | 22.4 | 3.8 | 56.2 | 0.132 |

| 3 × 185 | 925/0.50 | 2.4 | 24.8 | 4.0 | 61.8 | 0.108 |

| 3 × 240 | 1221/0.50 | 2.6 | 28.2 | 4.2 | 69.4 | 0.082 |

| Note: In addition to the above specifications, TSTCABLES can also customize high quality high temperature cables of various specifications and sizes according to different industries and application scenarios, please feel free to email us for more information. | ||||||

Characteristics of use

- 1. AC rated voltage: U0/U 450/750KV.

- 2.Maximum working temperature: polyperfluoroethylene propylene (F46) insulation does not exceed 200 ℃, soluble polytetrafluoroethylene (PFA) insulation does not exceed 260 ℃.

- 3. Minimum ambient temperature: PVC sheath: fixed laying -40℃, non-fixed laying -15℃, fluorine plastic and silicone rubber sheath: fixed laying -60℃, non-fixed laying -20℃.

- 4. Cable installation and laying temperature should not be less than 0 ℃ (fluorine plastic, silicone rubber and composite sheath cable not less than -25 ℃).

- 5. Allowable bending radius of the cable: non-armored cable is at least 6 times the outer diameter of the cable, copper tape shielded or steel tape armored cable is at least 12 times the outer diameter of the cable, fluorine plastic insulation and sheathing cable is at least 8 times the outer diameter of the cable.

Fire prevention measures

Adopt flame retardant cables. Adopt fireproof cable tray. Adopt fireproof coating. Install fireproof partition walls and fireproof baffles at cable tunnels and mezzanine exits. Exhaust cable should avoid oil pipeline, explosion-proof door, otherwise it should take local pipe penetration or heat insulation fire prevention measures.

Precautions

In the process of transportation and loading and unloading, the cable and cable tray should not be damaged, it is strictly prohibited to push the cable tray directly from the car, the cable should not be placed on the transportation, flat storage. Before transporting or moving the cable tray, it is necessary to ensure that the cable tray is firm, the cable is wound tightly, the oil pipe between the oil-filled cable and the pressure tank should be fixed and not be damaged, and the pressure tank should be firm, and the pressure indication should meet the requirements.

High-temperature cable features use

High-temperature cables are cables that can operate normally in high-temperature environments, usually referring to cables that can safely and stably transmit power signals and data signals at high temperatures above 200℃ or even 600℃. High temperature cables usually have the following characteristics:

- High temperature resistance: able to maintain excellent electrical and mechanical properties in sustained high temperatures, the material has excellent heat, flame and oxidation resistance properties.

- Anti-corrosion and anti-corrosion: not only resistant to high temperatures, but also resistant to corrosion and oxidation in high temperature environments.

- Low energy consumption: the cable is designed with low resistance, reactance and capacitance to ensure low energy consumption and safe and reliable operation under high temperature conditions.

- Anti-interference: It can stably transmit signals in high temperature environment with good anti-interference to ensure the accuracy of signals.

High-temperature cables have a wide range of applications, especially in high-temperature melting, power transmission, aerospace, nuclear energy and other important fields. In addition, with the rapid development of new energy vehicles and intelligent manufacturing, high temperature cables will also emerge more application scenarios.

High temperature cable main performance

The most significant performance of high temperature cable, first of all, is high temperature resistance. High-temperature cable insulation, winding, filling and sheath generally use fluorine plastic, silicone rubber, glass fiber, mica and other materials with strong resistance to high and low temperatures, it not only has a strong resistance to high temperatures, but also has a certain ability to withstand low temperatures.

When the operating environment of the cable is relatively harsh, the performance of ordinary cables will be greatly reduced or damaged, affecting the normal use of the cable, high-temperature cable insulation and high-temperature resistance, to ensure that the cable in the high-temperature operating environment of the cable performance is not destroyed, to ensure that high-temperature cable normal use.

High-temperature resistant cables are used in the field of electronics industry: temperature compensation wire, low-temperature resistant wire, high-temperature heating wire, aging-resistant wire, flame-retardant wire and so on;

High-temperature resistant cable in the field of household appliances industry for: air conditioning, microwave ovens, electronic disinfection cabinets, electric rice burgers, electronic hot water bottles, electric heaters, electric ovens, electric frying pans, lamps and lanterns lighting and other internal wiring;

High-temperature resistant cable in the enterprise high-temperature environment can be used for: boiler room, rolling mills, fax machines, printers, photocopiers, scanners and other machines of the internal connecting lines, instrumentation motor wiring, electronics, gas equipment and other high-temperature environment.

High-temperature resistant cables are also widely used in petrochemical, iron and steel, aerospace, shipbuilding, military, pharmaceutical, food, plastic machinery, boilers and other heat and high-temperature related industry sectors.

Ordinary cable in use for a period of time, easy to be affected by the environment becomes aging, so that the various performance parameters of the cable have a different degree of reduction, but high-temperature cable because of its advanced manufacturing process, making its anti-aging ability is very strong, can be used for a long time and will not be aging, on the whole, to enhance the service life of the cable.

High-temperature cable characteristics

High-temperature cables are made by adding special materials, and processing, compared with traditional cables, high-temperature cables in the characteristics of high temperature has absolute performance advantages. Therefore, the market price of high-temperature cables than ordinary cables to some higher, but for some high-temperature special environment, high-temperature cables play a role is not a simple price can be measured, and high-temperature cable in addition to high-temperature characteristics, there are many excellent performance.

First of all, of course, is the characteristics of high temperature resistance, which is also named high temperature cable, high temperature cable production materials and processes, are designed to make it better adapt to the high temperature environment, so the high temperature cable has a very good high temperature performance.

Secondly, the corrosion resistance of high-temperature cable is also excellent, in the process of using high-temperature cable, due to the environment and external factors will come into contact with some corrosive substances, it can maintain its nature very well, the chemical reaction is slow, so the use of time will be longer.

And high-temperature cable also has very good electrical insulation properties, high-temperature cable outer skin insulation can ensure that high-temperature cables will not leak when in use, in addition to high-temperature cables have flame resistance, aging resistance and other excellent characteristics. Therefore, high-temperature cables have excellent properties such as oil resistance, waterproof, abrasion resistance, resistance to acid, alkali and all kinds of corrosive gases, aging resistance, non-combustible, etc., which are suitable for metallurgy, electric power, petrochemical and other industries.

High-temperature cable use model

Widely used in aerospace, rolling stock, energy, iron and steel, non-ferrous metal smelting, oil mining, electrical machinery and other fields. Long-term continuous operating temperature of 125 degrees, 135 degrees, 150 degrees, 180 degrees, 200 degrees, 250 degrees and 250 degrees above the high-temperature-resistant cables, currently in common use are irradiated coupled with polyolefin stems, silicone rubber, fluorine resin, polyimide, mica, magnesium oxide and other cables.

High temperature resistant cable models

1、Polyethersulfone insulated cable

Excellent heat resistance, physical and mechanical, electrical insulation, extrusion molding, at high temperatures, to maintain stable performance and other advantages, the heat distortion temperature of 200-220 degrees, the continuous use of the temperature of 180-200 degrees, ul temperature index of 180 degrees. Resistant to 150-160 degrees hot water or steam, not subject to acid, alkali erosion. Modulus of elasticity at 100-200 degrees almost unchanged, small coefficient of linear expansion, small temperature dependence, non-toxic, recognized by the U.S. DA, self-extinguishing, without adding any flame retardant.

2、Polyetheretherketone insulated cable

Polyether ether ketone belongs to the super heat-resistant thermoplastic resin, long-term continuous use temperature of 250 degrees, ul temperature index of 250 degrees. peek is a flexible resin, creep resistance, self-extinguishing, and do not add any flame retardant can meet the requirements.

3、Heat-resistant silicone rubber insulated silicone rubber sheathed cable

Applicable to household appliances, lighting fixtures, combustion equipment and other high temperature environment. Divided into tinned copper core silicone rubber insulated high temperature flexible cable, tinned copper core silicone rubber insulated braided shielded high temperature flexible cable, tinned copper core silicone rubber insulated high voltage line, tinned copper core silicone rubber insulated medium-sized rubber sheathed flexible cable, tinned copper core silicone rubber insulated heavy duty rubber sheathed flexible cable.

High temperature cable insulation materials

1. Polychlorotrifluoroethylene (PCTFE)

Polychlorotrifluoroethylene (PCTFE), there are two kinds of polymers and oligomers, oligomers used as fluorine oil: the molecular weight of the polymers are categorized according to the different uses. According to its loss of strength temperature is divided into two grades, the first grade of the loss of strength temperature in the 240-270 ° C; the second grade of the loss of strength temperature in the 270-300 ° C, the molecular weight of the molecular weight of about in the range of 3×10 (5 times) -6×10 (5 times).PCTFE in wire and cable is mainly used as a high-temperature-resistant installation of the wire insulation and sheathing materials.

2. Polyvinylidene fluoride PVDF

Polyvinylidene fluoride (PVDF) is a kind of fusible fluoroplastic which is more commonly used nowadays, it is the homopolymer of vinylidene fluoride, it has excellent corrosion resistance, dirt resistance, weather resistance and ultraviolet irradiation resistance, and it can be crosslinked by radiation to improve the mechanical properties. Typically, it is used as a coating and lining for chemical pipes, chemical parts and containers. However, the tensile strength of PVDF is two times greater than polytetrafluoroethylene, compression strength of six times greater, abrasion resistance is similar to nylon, excellent weathering, radiation resistance, coloring, can withstand 10 six times Gy of Y-ray irradiation, non-combustible, less fuming, encounter high heat with a high rate of carbonization so that it is not flammable, so it is also commonly used in the preparation of low-frequency cable insulation, such as ceiling compartment cables, flame-retardant cables, Heating cable or optical fiber, etc.

3. Polytetrafluoroethylene PTFE

Polytetrafluoroethylene abbreviation F4, is * representative of perfluorinated plastics, commonly known as “Plastic King”. PTFE has excellent heat resistance (can be used for a long time at 260 ℃), excellent resistance to chemical media, flame retardant, low smoke and excellent electrical properties, is the ideal material for many high-temperature cable.

Polytetrafluoroethylene melting point of 327 ° C, at this high temperature its melt turnover up to 10 times 10 Pa – s, and in the amorphous state for the shear stress is very sensitive to melt rupture. Therefore, can not use the usual extrusion process for wire and cable insulation Bi coating, but only the method of powder metallurgy molding, that is, through the pre-molding, sintering, cooling steps to make the insulation molding.

4. Polyperfluoroethylene propylene FEP

Polyperfluoroethylene propylene (FEP) is a copolymer of TFE and hexafluoropropylene (HFP), referred to as F46. It is a fully fluorinated fluoroplastic, hardness and strength of PTFE, but the use of temperature is lower than that of PTFE 50 ° C. FEP has a better weathering, irradiation resistance, chemical stability is also good. Like PTFE and PFA, FEP’s insulating properties are quite outstanding. Combined with its own flame retardancy, low smoke generation, and ease of processing, this makes FEP an ideal material for local area network (LAN) cable insulation. *With a high resistance of 205°C, it can be used for heating cables, thermocouples, and automotive high-temperature cables.

5.Tetrafluoroethylene-ethylene copolymer ETFE

ETFE is following PTFE (F4) and FEP (F46), fluorine plastic development of the third major varieties, referred to as F40. is a kind of both similar to the excellent performance of polytetrafluoroethylene, but also has a good sound permeability and weather resistance, permeability, non-toxic, solvent and irradiation-resistant fluorine plastic; is a strong fluorine plastics, with excellent resistance to abrasion and abrasion. ETFE can also be resistant to high temperature of 150 ℃, after crosslinking ETFE can be resistant to high temperature of 200 ℃. ETFE can also withstand high temperature of 150℃, after crosslinking ETFE can withstand high temperature of 200℃. At the same time, it is also one of the fluoroplastics that are difficult to process.ETFE is mainly used in wires and cables that need to be flame-retardant, low fuming, resistant to chemical mediums, as well as resistant to scuffing and abrasion. It can be used to prepare various specifications of wires and cables, such as automobile, aviation cables and heating cables.

6.Tetrafluoroethylene-perfluoroalkyl vinyl ether PFA

Tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer by perfluoroalkyl vinyl ether modified polytetrafluoroethylene resin, referred to as PFA, commonly known as soluble PTFE, also known as “Perfluoroalkoxy fluorine plastics”, but also fluorinated fluorine plastics, which improves the shortcomings of the processing of polytetrafluoroethylene difficult to maintain all the advantages and disadvantages of PTFE, making its performance and long-term use. It improves the disadvantages of PTFE processing difficulties and maintains all the excellent properties of PTFE, so that its performance and long-term use of temperature is basically close to or maintain the level of PTFE.PFA has the same basic characteristics as PTFE, with better plasticity and high strength, but can be processed by melt extrusion method, and it can be processed by melt processing at a lower temperature. Therefore, in the wire and cable products where the requirements of PTFE characteristics and PTFE can not be processed, can be replaced by PFA. Wire and cable production, PFA is more expensive, therefore, usually used for high current, high temperature cable. Such as special heating cables, thermocouples and automotive high-temperature cable.

7. Fluorine elastomer

Fluorine elastomer, also known as fluoroelastomer, it is a class of fluorine-containing synthetic rubber, is heat and oil resistance * good synthetic rubber, has been applied to the harsh use of the environment. The main types of fluoroelastomers are VDF-HFP fluoroelastomers, TFE-Pr fluoroelastomers, VDF-HFP-TFE fluoroelastomers, VDF-TFE-PMVE fluoroelastomers, fluoro-silicone rubbers, and TFE-PMVE fluoroelastomers.

Among them, binary copolymer fluoroelastomers are widely used because of their excellent heat resistance, oil resistance, chemical resistance and small compression deformation. Especially VDF-HFP fluorine rubber in the characteristics, processability, price and other aspects of the balance and more widely used. At present, this type of fluorine elastomer in the wire and cable on the application is relatively small, mainly used in the military field and aerospace, aviation and automotive industry. Need more wire and cable related knowledge.

8.THV fluorine plastic

THV is a fluoroplastic with excellent performance developed in 1980s, THV fluoroplastic is made of tetrafluoroethylene (TFE). Hexafluoropropylene (HFP) and vinylidene fluoride (VDF) copolymerization (different proportions, different polymer properties), is a partially crystallized thermoplastic, it has fluoroplastic weathering, heat resistance, non-combustible in addition to easy adhesion, chemical resistance, good impermeability, good flexibility (bending modulus of 80-490MPa), THV material processing temperature (165-180°C) than most of the THV material processing temperature (165-180 ° C) than most other fluoropolymer processing temperature is significantly lower, so can be commonly used in the construction of processing equipment, but also with ordinary hydrocarbon plastics or elastomers together with the composite processing. And THV has excellent resistance to chemical media and electrical properties, is a soft fluoroplastic, its electrical properties are not suitable for high-speed data communication network (i.e. Category 5 cable) in the insulation, but in those places where flexibility is required, there are its unique advantages.

In addition, THV can be used in those applications where drilling and bonding with other materials is required. THV can be used for fiber optic cladding because of its excellent optical properties and high transmittance of various wavelengths of light, which makes it particularly suitable for applications requiring high optical transmittance. Special wires and cables prepared with THV fluoroplastics have important applications in aviation, aerospace, instrumentation, automotive and other fields, and in recent years, there are wires and cables prepared with THV fluoroplastics in special environments such as short-distance communication networks. Due to its many excellent properties, new uses of THV fluoroplastics are being developed continuously.

High Temperature Cable Prices

Due to the different brands, models and manufacturers of high temperature resistant cables, of course the price of high temperature resistant cables will also vary. So what is the price of high temperature resistant cable? The price of high temperature resistant cable ranges from $300 if you count it by roll. If you calculate by meter, it is just a few dollars per meter.If you have high temperature cable customization needs, please feel free to email TSTCABLES for a detailed quote.

The maximum high temperature cable can withstand

Before talking about high temperature wires, it is necessary to understand what the operating temperature of ordinary wires and cables is. Usually, the common insulation materials for ordinary cables are polyethylene, polypropylene and polyvinyl chloride, etc., and the cables made of such materials are generally able to operate at 70C~90C in the long term.

The insulation layer of high temperature resistant wire is used PA Teflon, it is because this material has a very good high temperature resistance, so it makes its production of wire can be in 180 ° C and above the environment of long-term operation. If you want to talk about the maximum number of degrees of high temperature wire can withstand, it is 200C. However, at 200C high temperature, even high temperature wires can not run for a long time, only for a shorter period of time, otherwise they are also prone to failure.

Ways to identify poor quality high temperature cable

Identify inferior high-temperature cable method, you can first look at the conductor copper wire color, the national industry standard (national standard) provides for cable conductor copper wire must be selected from pure copper, which is oxygen-free copper (industry known as copper, commonly known as red copper). Oxygen-free copper copper content of 99.9%, higher purity, bright and soft color, higher oxygen content and other impurities in the copper color dark, brightness is relatively low. Secondly, you can also carry out the copper wire wiping method to identify, wipe the copper wire with white paper. As unqualified copper wire containing more impurities, and copper fusion is not stable, so after wiping will leave black traces on the white paper, you can also physically bend the copper wire, pure copper wire is softer, tensile strength is better, is not easy to break the phenomenon, and a little bending on the fracture should be unqualified products.

The future development trend of high-temperature cable

- Energy efficient design: With the popularization of energy saving and environmental protection concept, the future of high temperature cable will pay more attention to energy efficiency and environmental friendliness.

- Standardization and enhancement of technical standards: the development of the global power industry will promote the continuous improvement of high-temperature cable technology standards and quality requirements.

- The application of new materials: such as carbon nanotubes, graphene and other new materials, is expected to provide new possibilities for high-temperature cable performance enhancement.

- Intelligent technology application: the development of Internet of Things, artificial intelligence and other technologies will make high-temperature cables develop in the direction of intelligence.

The world’s leading supplier of high-quality high-temperature cables–TSTCABLES

In the hot summer, high temperature is hard to resist, the safety and stability of power transmission is crucial. Choose TSTCABLES professionally manufactured high temperature cables to keep your power system stable in the heat!

TSTCABLES high-temperature cables, which stand out for their excellent high-temperature resistance, are able to maintain superb electrical performance and stability at extreme temperatures. High-quality materials and excellent workmanship ensure the durability and reliability of the cables.

Whether it’s a metallurgical furnace, chemical reactor or aerospace equipment, our high temperature cables can easily cope with it, guarding your electrical equipment safe and worry-free. If you have questions and needs about high temperature cables, please feel free to email us!

Also available in:

English