Fire-resistant cables are cables that can maintain safe operation for a certain period of time in the case of flame combustion. China’s national standard GB12666.6 (and other IEC331) will be fire-resistant test A, B two levels, A flame temperature 950 ~ 1000 ℃, the duration of the fire time of 90 min, B flame temperature 750 ~ 800 ℃, the duration of the fire time of 90 min, the entire test period, the specimen should be subjected to the product’s specified value of the rated voltage.TSTCABLES new type of fire-resistant The cables are widely used in rail transportation, military, aviation, shipping, oil and gas, nuclear power plants, wind farms, high-rise buildings, underground railway cables, underground streets and important industrial and mining enterprises and other places related to fire safety and fire rescue, such as power supply lines and control lines for fire-fighting equipment and emergency facilities such as emergency guide lights.

Fire-resistant cable use environment

1.AC rated voltage:

U. / U (V series: 600/1000V, K series: 450/750V, B series: 450/750V).

2.Maximum long-term working temperature of the cable:

(1) alkene-resistant polyfluoroethylene insulation and sheath: 70℃ and 105℃ both; cross-linked polyethylene insulation: 90℃;

(2) Fluorine plastic insulation and sheath: 220 ℃ and 260 ℃ two; fluorine plastic insulation and 105 ℃ flame retardant polyfluoroethylene sheath: 90 ℃ and 125 ℃ two;

(3) Low-halogen, low-smoke flame-retardant PVC insulation and sheath: 70℃; halogen-free, low-smoke flame-retardant polyolefin insulation and sheath: 90℃ and 125℃.

3. Minimum ambient temperature:

(1) Flame retardant PVC insulation and sheath: fixed laying -40℃; non-fixed laying -15℃;

(2) fluorine plastic insulation and sheath: fixed laying -60 ℃; non-fixed laying -20 ℃.

4. Cable safety laying temperature

Not less than 0℃.

5. Fire resistance characteristics:

Comply with GA 306.2-2007, GB/T 19216.21-2003.

Flame Temperature Flame Temperature 950℃-1000℃ Flame Temperature 750℃-800℃

Burning time Burning time 90min (recommended) Burning time 90min (recommended)

Additional voltage Rated voltage (min. 100V) Rated voltage (min. 100V)

Fire Resistance Class A (Class IA~IVA) Class I~IV

Laying the recommended permissible bending radius:

Non-armored, braided shielded cable shall be not less than 6 times the outer diameter of the cable;

Steel tape armored cable shall be not less than 12 times the outer diameter of the cable;

Fluorine plastic insulation and sheath material cable shall be not less than 8 times the outer diameter of the cable.

Classification of fire-resistant cable

Fire-resistant cable according to the national experimental standards (GB12666-99) can be divided into two classes: NHA, NHB; in general product naming, NHA is usually expressed in GNH, is said to be high fire-resistant cables.NHB in general fire-resistant products is expressed as NH.

Category B cables are able to withstand combustion in the flame at 750 ℃ ~ 800 ℃ and rated voltage for at least 90min without cable breakdown (i.e., 3A fuse does not blow).

In improving the fire-resistant layer manufacturing process and increase the fire-resistant layer and other methods on the basis of the development of a class A fire-resistant cable, which can be in the flame at 950 ℃ ~ 1,000 ℃ and rated voltage to withstand combustion for at least 90min and the cable is not broken (that is, 3A fuse does not blow).

The fire-resistant performance of Class A fire-resistant cables is superior to that of Class B. In addition, mineral insulated cables are fire-resistant cables in a better performance, it is processed from the copper core, copper sheath, magnesium oxide insulation materials, referred to as MI (mineral insulated cables) cable. The cable is entirely composed of inorganic materials constitute a fire-resistant layer, while the fire-resistant layer of ordinary fire-resistant cables is composed of inorganic materials and general organic composite, so the fire-resistant performance of MI cables is better than ordinary fire-resistant cables and will not be decomposed due to combustion of corrosive gases. MI cables have good fire-resistant properties, and can be long-term work at a high temperature of 250 ° C. At the same time, there are also explosion-proof, corrosion-resistant, high current-carrying capacity, radiation-resistant, high mechanical strength, small size, and high performance, and can be used for a variety of applications. MI cable is characterized by high mechanical strength, small size, light weight, long service life and no smoke. But the price is expensive, complex technology, construction difficulties, in the oil irrigation areas, important wood structure public buildings, high-temperature places and other fire-resistant requirements of high and acceptable economic occasions, can be used in this fire-resistant performance of the cable.

Fire-resistant cable structure characteristics

Fire-resistant cable structure and ordinary cable is basically the same. The difference is that the conductor of the fire-resistant cable is made of copper wire with good fire-resistant performance (the melting point of copper is 1083℃), and a fire-resistant layer is added between the conductor and the insulation layer. The refractory layer is made of multi-layer mica tape. Since the allowable working temperature of different mica tapes varies greatly, the key to determining the fire resistance of the cable is the mica tape.

Fire-resistant cable has good fire-resistant characteristics and can work under 250℃ high temperature for a long time, as well as explosion-proof, corrosion-resistant, high current-carrying capacity, radiation-resistant, high mechanical strength, small volume, light weight, long service life, and non-smoke characteristics.

Fire-resistant cable characteristics

The cable can still maintain the normal operation of the line for a period of time under burning conditions. In layman’s terms, in case of fire, the cable will not burn at once, the circuit is safer.

Advantages of fire-resistant cables

1. In case of fire, the amount of smoke is less, which buys time for people fleeing from the scene;

2. excellent flame retardant properties, fire-resistant wire can ensure that the line in the event of a fire in a certain period of time normal energization, transmission of a variety of control signals, alarm signals, so the product has a certain period of time in the flames of the power supply capacity;

3. The copper sheath itself is a good grounding wire, so it can be a good guarantee of personnel safety;

4. have good corrosion resistance, generally do not need special protective measures. Unless it is in the place of serious chemical corrosion, plastic sheath can be used to protect the copper sheath;

5. The whole of the fire-resistant cable is made of inorganic materials, so the whole fire-resistant wire is neither easy to burn nor delayed combustion;

6. the cable adopts seamless copper sheath, even if it is immersed in water, it can be energized for a long time to run, and it is waterproof;

7. Compared with other models with the same core cross-section, fire-resistant cables can run continuously for a long time, with high current-carrying capacity and strong overload capacity.

It is the special advantages of fire-resistant cable, destined to fire-resistant cable in the fire requirements of a wide range of places, such as: fire pumps, fire alarm system manual alarm line, high-rise buildings or airports, subways and other places. It is not difficult to see that, with the development of modern industry, the advantages of fire-resistant cable will make it occupy an irreplaceable position in the wire and cable industry.

Fire-resistant cable model meaning

Model composition

Flame-retardant and fire-resistant wire and cable model by the product combustion characteristics of the code and the relevant wire and cable model consists of two parts.

Combustion characteristics code table

| Nicknames | Name (of a product) |

| Za | Flame retardant |

| ZA | Flame Retardant Class A |

| ZB | Flame retardant B |

| ZC | Flame retardant C |

| ZDb | Flame retardant D |

| omit | Halogenated |

| W | Halogen free |

| D | Low smoke |

| U | Low toxicity |

| N | Fire Resistant |

| NJ | Fire and Impact Resistant |

| NS | Fire resistant plus water spray |

| aZ is single-root flame retardant, only for products whose base material does not contain halogens. If the base material contains halogens, Z is omitted. bZD is bundle burning category D, applicable to the outer diameter of not more than 12mm, i.e., thinner products. |

Fire-resistant cable common model

NA-YJV/NB-YJV

Cross-linked polyethylene insulated PVC sheathed Class A(B) fire-resistant power cable

It can be laid in rooms, tunnels and pipelines where fire resistance is required.

NA-YJV22/NB-YJV22

Cross-linked polyethylene insulated steel tape armored PVC sheathed class A(B) fire-resistant power cables

Suitable for underground laying when fire resistance is required, not suitable for laying in pipelines.

wdna-yjy/wdnb-yjy

Cross-linked polyethylene insulated polyolefin sheathed class A(B) halogen-free and low-smoke fire-resistant power cables

It can be laid in rooms, tunnels and pipelines where halogen-free and low-smoke fire-resistant is required.

wdna-yjy23/wdnb-yjy23

Cross-linked polyethylene insulated steel tape armored polyolefin sheathed class A(B) halogen-free and low-smoke fire-resistant power cables

Suitable for halogen-free low-smoke and fire-resistant requirements of buried laying, not suitable for pipeline laying.

The basic function of fire-resistant cable

Fire-resistant cables are made of copper and other metals as conductors, insulating materials as components, through the insulation and protective sheath so that the conductive part and the non-contact part of the close contact and the formation of a whole with a certain degree of strength, so that the conductive part of the fire environment to maintain a certain degree of stability throughout the conductive part of the fire.

Scope of application of fire-resistant cables

Fire-resistant cables can maintain normal power supply for a period of time in the event of a fire. This feature determines that fire-resistant cables play an important role in modern urban and industrial buildings, because once a fire occurs, the power supply circuits of the control, monitoring, guidance and alarm systems must be maintained in order to work properly. Therefore, they are mainly used in the power supply circuits from the emergency power supply to the user’s fire-fighting equipment, fire alarm equipment, ventilation and smoke extraction equipment, guide lights, emergency power sockets, and emergency elevators.

Reason for fire resistance

Since the whole is composed of inorganic materials, the whole fireproof cable does not burn or deflagrate. And can withstand fire. Tests have shown that: in the flame 800 ~ 900 in the burn 2 hours, the cable has been normal energized operation, in the 1000 flame burning 30 minutes is still intact, continue to operate normally. General normal working temperature of 250, safe and reliable operation.

Application areas of fire-resistant cables

Construction field: Fire-resistant cables are widely used in high-rise buildings, especially those places with high fire safety requirements. Since fire-resistant cables can maintain normal operation for a period of time in a fire, it can provide stable power support for the building’s fire protection system, emergency lighting, evacuation instructions and so on.

Transportation: Fire-resistant cables also play an important role in transportation facilities such as subways and tunnels. Once a fire occurs in these places, the consequences will be unimaginable. Fire-resistant cables are able to maintain electrical signal transmission and power supply functions in high temperatures and flames, providing the necessary support for emergency evacuation and rescue.

Power and industrial and mining enterprises: power stations, nuclear power plants and important industrial and mining enterprises are also the main application areas of fire-resistant cables. These places have extremely high requirements for the stability and safety of the power system, and fire-resistant cables can safeguard the normal operation of the power system in case of fire and other emergencies, preventing greater losses caused by power interruptions.

Fire fighting system:

Power supply lines and control lines of fire pumps and sprinkler pumps.

Power supply and control system of fire elevator.

Manual alarm lines for fire alarm systems, and fire broadcast and telephone lines. All of these need to remain operational during a fire in order to provide timely alarms and direct evacuation.

Fire safety facilities:

Power supply and control lines for fire shutter doors and motorized fire doors.

Smoke prevention and exhaust system, including power supply control lines for smoke exhaust fans, smoke exhaust valves and fire dampers. These facilities have fire resistance time requirements in a fire, and fire-resistant cables can ensure their normal operation.

Emergency lighting and indicating systems:

Centrally supplied emergency lighting circuits, as well as control and protection power circuits. These systems are critical to directing evacuation in a fire.

Electrical Systems and Critical Facilities:

Critical relay protection lines and operating power lines in large and medium-sized substations. Fire-resistant cables ensure the stable operation of power systems in emergency situations such as fires.

Special industrial environment:

High-temperature environment, such as the smelting workshop in metallurgical industry, glass kiln in building materials industry.

Occasions with strong radiation, such as nuclear power plants or nuclear reactors, electron gas pedals and so on. In these environments, fire-resistant cables can withstand extreme conditions and maintain the stability and safety of the circuit.

Security and monitoring systems:

Security CCTV circuits in high-rise buildings or important facilities such as airports and subways. These systems require a constant and stable power supply to ensure the continuity of security surveillance.

Data transmission and communication systems:

Lines that need to maintain data transmission and communication during a fire, such as computer monitoring lines. Fire-resistant cables can ensure the smooth transmission of data and information in emergency situations.

Fire-resistant cables are widely used in high-rise buildings, underground railroads, underground streets, large power stations and important industrial and mining enterprises and other places related to fire safety and firefighting life-saving, such as power supply lines and control lines for firefighting equipment and emergency facilities such as emergency guide lights.

Different fire-resistant cable models and applications

1. NH-KVV type flame retardant cable

NH-KVV type flame retardant cables are suitable for power transmission and distribution cables in AC power system. Its main technical indexes include rated voltage of 0.6/1kV, rated temperature of 70℃, good flame retardant performance, safety and reliability.

2. WDZ-KYJY fire-resistant cable

WDZ-KYJY fire-resistant cable is suitable for power supply cable of electricity, lighting and electrical equipment inside buildings. Its main technical indexes include rated voltage of 0.6/1kV, rated temperature of 90℃, good fire resistance and high temperature resistance.

3. NH-YJV type flame retardant cable

NH-YJV flame retardant cable is suitable for AC power system transmission and distribution cable. Its main technical indexes include rated voltage of 0.6/1kV, rated temperature of 70℃, good oxidation and corrosion resistance.

4. NH-BVV type flame retardant cable

NH-BVV type flame retardant cable is suitable for indoor building wiring cable. Its main technical indexes include rated voltage of 450/750V, rated temperature of 70℃, high ignition temperature and slow burning speed.

5. ZR-KVVP type flame retardant cable

ZR-KVVP flame retardant cable is suitable for indoor wiring between electrical equipment or cable wells. Its main technical indexes include rated voltage of 450/750V, rated temperature of 70℃, safe and reliable, good corrosion resistance.

There are various types of fire-resistant cable models, each applicable to different uses and occasions, different specifications and parameters also have different characteristics and advantages accordingly. Therefore, TSTCABLES suggests that you should make scientific and reasonable choices according to the actual needs and requirements when selecting and using fire-resistant cables to ensure the safe, reliable and stable operation of the power system.

Fire Resistance Time

Fire-resistant cables are suitable for particularly important occasions of 1KV and the following power or control system lines, when the line in case of fire, fire-resistant cables can resist the high temperature of 750-800 ℃ for more than 90 minutes, to ensure the safety of power supply, in order to win enough time to extinguish and mitigate the disaster. Therefore, the cable is widely used in petrochemical, metallurgy, high-rise buildings and other important places. Fire-resistant cables are divided into two categories, A and B. The high temperature of A category is as high as 950-1000℃, and B category reaches 750-800℃, and B category is usually chosen, which is indicated by NB or NH.

Fire-resistant grade

1.IEC60331-1999, the fire temperature requirements for 750 ℃ / 3h level, that is, at 750 ℃ under the level of 300 volts applied to burn 3 hours without breakdown.

2.BS6387 requirements through the horizontal combustion test, water spray test and mechanical shock vibration combustion test.

Horizontal combustion test for A level 650 ℃ / 3h, B level 750 ℃ / 3h, C level 950 ℃ / 3h and S level 950 ℃ / 3min.

Class A indicates that it will not break down after 3 hours of horizontal burning at 650℃ with 300 volts applied;

Class B indicates no breakdown after 3 hours of burning at a voltage level of 300 volts applied at 750℃;

Class C indicates no breakdown after 3 hours of burning at 950℃ with 300V applied;

Class S indicates no breakdown after 3 minutes of burning at 950℃ with 300V applied.

The water spray combustion test is divided into W level, which indicates that it does not break down after applying 300V for 15 minutes and then water spray combustion for 15 minutes.

The shock and vibration burning test is categorized into X class 650℃/15min, Y class 750℃/15min and Z class 950℃/15min.

Class X indicates that the mechanical shock vibration is applied at 650℃ for 15 minutes without breakdown while burning at 300 volts every 30 seconds;

Class Y indicates no breakdown at 750°C for 15 minutes with mechanical shock vibration every 30 seconds while burning at 300 volts;

Class Z means no breakdown by mechanical shock vibration for 15 minutes at 950°C for 30 seconds while burning at 300 volts.

BS6387 requires the highest grade to be CWZ.

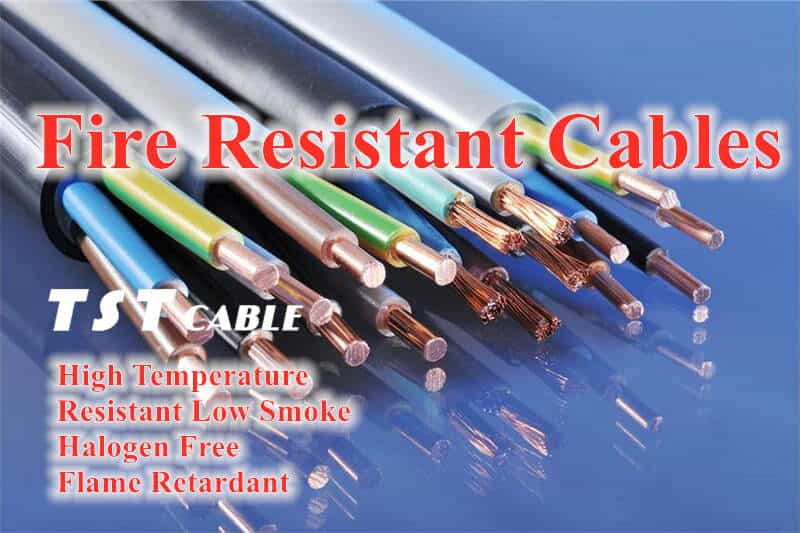

TSTCABLES is the world’s leading manufacturer of high-quality fire-resistant cables

TSTCABLES fire-resistant cables, the safe choice! Our fire-resistant cables are manufactured from high-quality materials and rigorously tested to ensure consistent performance even under extreme conditions. Its excellent fire resistance characteristics, the use of new high-quality flame-retardant materials, durable, effective in reducing safety hazards, able to keep the circuit open in the fire, for your equipment and life safety.

Also available in:

English