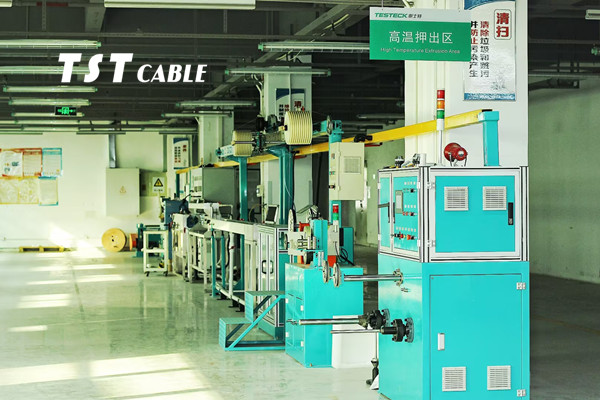

TST CABLES production workshop, Building 3, Security Technology Industrial Park, Guangming District, Shenzhen, October 30, 2024-TST CABLES announced that its newly introduced PEEK cable/TPI cable production line and equipment will be officially put into operation. The production line is designed for the production of high-performance PEEK round wire and TPI round wire, marking another milestone for the company in the field of high-end cable manufacturing.

Highlights of PEEK cable TPI cable production line equipment

The new equipment is highly intelligent and automated, which not only improves production efficiency, but also greatly improves product quality. According to the equipment operator, the main function of the production line is to produce special cables made of PEEK and TPI materials. Through the design of high control precision and high speed, the production efficiency and product quality are greatly enhanced.

Advantages of PEEK cable TPI cable

Due to its excellent performance, PEEK cable TPI cable has demonstrated its unique advantages in a variety of extreme environments:

High temperature resistance: suitable for high temperature environments.

Chemical stability: able to resist corrosion from a variety of chemicals.

Mechanical strength: Suitable for applications that need to withstand greater mechanical stress.

Electrical performance: Suitable for high-frequency signal transmission and high-voltage applications.

Radiation resistance: Suitable for environments that require resistance to electromagnetic interference and radiation.

PEEK cable TPI cable equipment operation process

TST CABLES technical experts introduced the operation process of the equipment to the author, including seven steps: wire release, preheating, glue extrusion, outer diameter control, process treatment, cooling and wire reeling. Among them, the tension control of wire reeling, the degree of plasticization of the rubber, the outer diameter size and process treatment are the key steps that need special attention during the operation.

PEEK cable TPI cable equipment use experience

A cable engineer from TST CABLES said that the new equipment is extremely easy to operate, with high control accuracy, significantly improved intelligence, and significantly improved production efficiency and product quality. The engineer explained while operating the equipment skillfully.

“The biggest advantages of this equipment when in use are simple operation, precise control, high efficiency and good product quality.”

“To ensure the long-term and stable operation of the equipment, daily maintenance work mainly includes lubrication of rotating parts, safety inspection of electrical parts, sealing of water and gas pipelines and cleaning of various parts. For simple troubleshooting, it mainly relies on adjusting process parameters to meet quality requirements.”

Technological innovation of PEEK cable and TPI cable

In terms of technological innovation, TST CABLES technical expert Li Gong pointed out that the intelligence and automation level of equipment will be further improved in the future. He said confidently: “We believe that with the development of technology, PEEK cables and TPI cables will be more widely used in all walks of life around the world.”

Equipment procurement decision

Speaking of equipment procurement decisions, TST CABLES senior management said: “This equipment was chosen because PEEK and TPI are both new special materials that require special equipment to match their special properties.” To this end, the company fully considered the performance requirements of new materials in the procurement decision process and finally chose this new equipment specially designed for new materials.

Increase investment to lead global special cable technology innovation

According to TST CABLES management, the total investment in the production line equipment is close to RMB 13.8 million. After the equipment is put into operation, the output and quality of PEEK, TPI/PE new material products will be greatly improved, and the company is expected to gain greater benefits.

Mr. Li, head of the technical department of TST CABLES, told the author that he is confident about the market prospects of PEEK and TPI/PI cables. “With the continuous expansion of the application of PEEK cables and TPI cables in multiple fields, the market demand for such products will continue to grow.”

The launch of the new PEEK cable production line not only reflects TST CABLES’s leading position in the field of high-end cable manufacturing, but also lays a solid foundation for the company’s future development. We look forward to this advanced production line to bring more opportunities to the company and provide customers with better products and services.

About TST CABLES

TST CABLES is a direct subsidiary of Shenzhen Test Technology Co., Ltd. It is an enterprise focusing on the production and research and development of high-end special cables, and is committed to providing high-performance, high-reliability high-temperature cable solutions to global customers. Through continuous innovation and technological progress, the company has become a leader in the industry. The newly put into operation PEEK cable and TPI cable production lines once again demonstrate the company’s unremitting pursuit of high-temperature cable technology innovation.

As a leading Chinese high-temperature cable manufacturer, TST CABLES has more than 20 years of professional experience and technical accumulation. Our production base is equipped with the most advanced production equipment, with a 10,000 square meter production workshop, 6 independent production lines (low smoke halogen-free large cross-section (240mm) production line, low smoke halogen-free cable production line, silicone cable production line, Teflon cable production line, PI cable production line, PEEK cable production line) and passed ISO9001 quality management system certification to ensure that every meter of cable meets the most stringent quality standards. We have a high-quality R&D team that continues to innovate, keep up with the cutting-edge technology of the industry, and is committed to providing customers with the best quality products and services.

TST CABLES’s leadership and technical experts demonstrated to users its professional strength and technological leadership in the field of PEEK cable production, and also expressed a positive attitude towards future market development.

Also available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese

Portuguese (Brazil)