In many popular industries today, such as offshore wind power, ships, rail transit, industry, etc., the importance of cable and pipeline penetration sealing is becoming more and more prominent. Offshore wind power platforms have long been subjected to sea breeze, waves, and salt spray. Ships need to resist seawater corrosion and fire hazards. Rail transit must ensure personnel safety and stable system operation. Super-large industrial projects have extremely high safety requirements for energy and material transmission. Once the cable and pipeline penetrations are not well sealed, it may cause serious consequences such as seawater backflow, fire spread, toxic gas leakage, and energy loss, which will not only endanger the safety of life and property, but also cause huge economic losses.

TST CABLES modular cable and pipeline penetration sealing system was born to solve these key problems. Like a loyal guard guarding the operation of various industries, it firmly controls the key lines of defense for safety and stability and plays an indispensable core role in many fields.

Collection of cross-field application cases

Hydropower field:a solid backing for hydropower stations

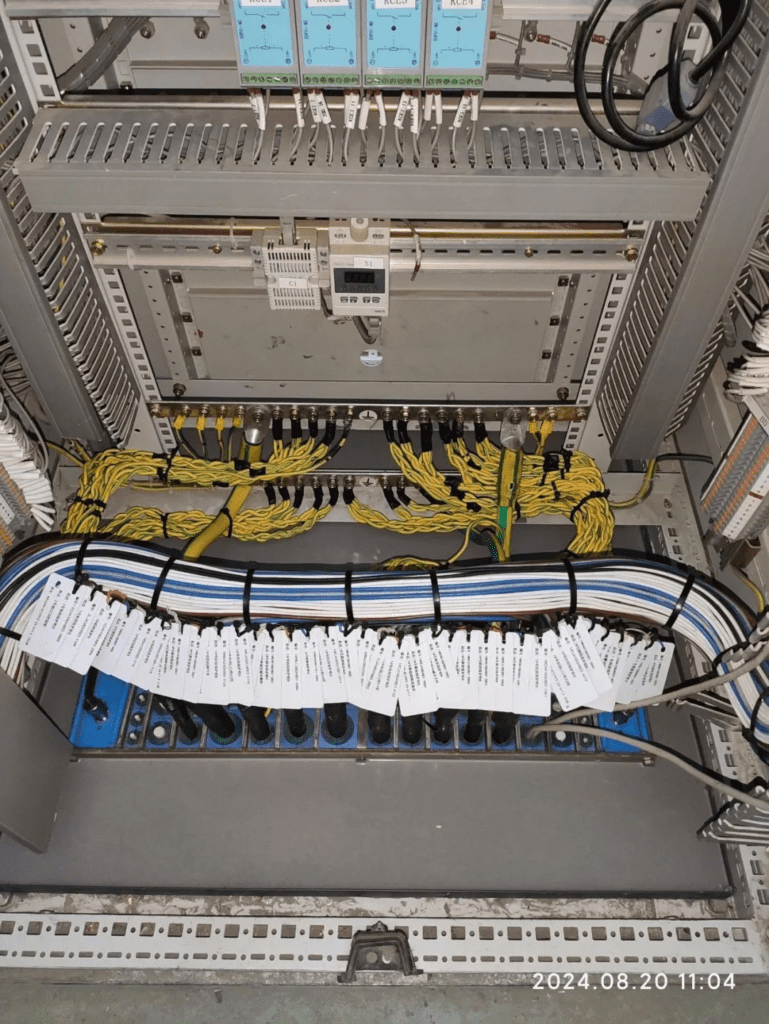

A large hydropower station in the Jinsha River Basin is one of the largest hydropower stations under construction in the world. The environment is extremely complex. The cabinets are exposed to wind, rain, and dust. The strong vibration generated by the unit during operation threatens the connection stability of the equipment in the cabinets at all times, causing the connectors to loosen, and the monitoring data of precision instruments and sensors to be frequently distorted, seriously affecting the performance of the equipment. In addition, harsh conditions such as high temperature, low temperature, corrosion, and condensation constantly erode the cabinet material, greatly shortening its service life. At the same time, the wiring inside the cabinet is messy and difficult to repair. Once the equipment fails, the hydropower station has to shut down for maintenance, the power generation efficiency drops sharply, and the maintenance cost soars.

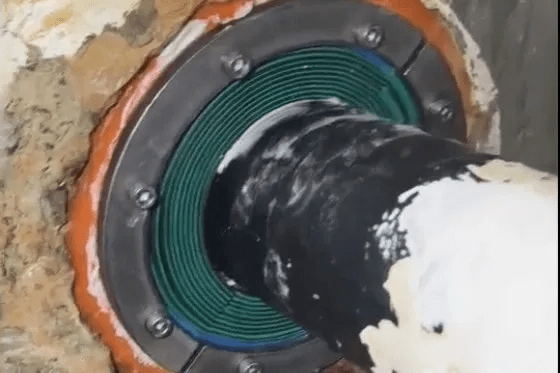

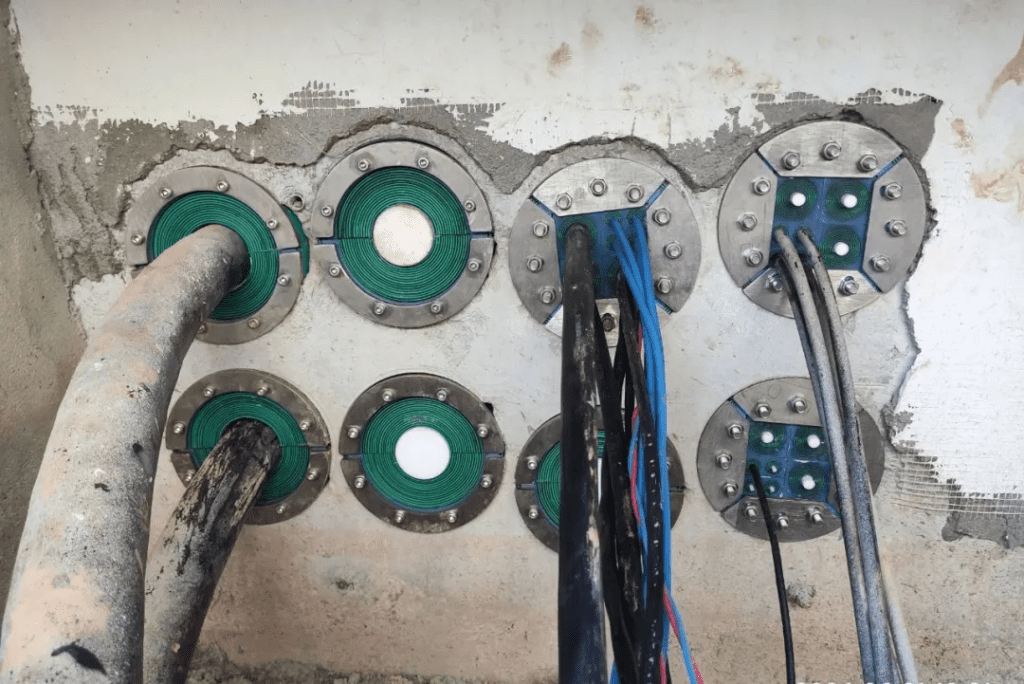

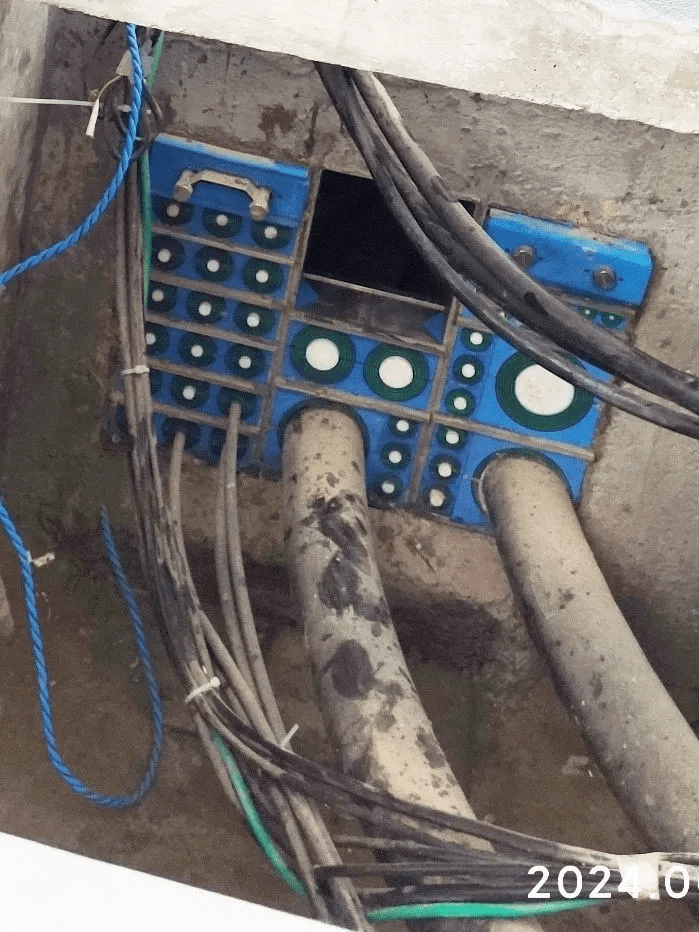

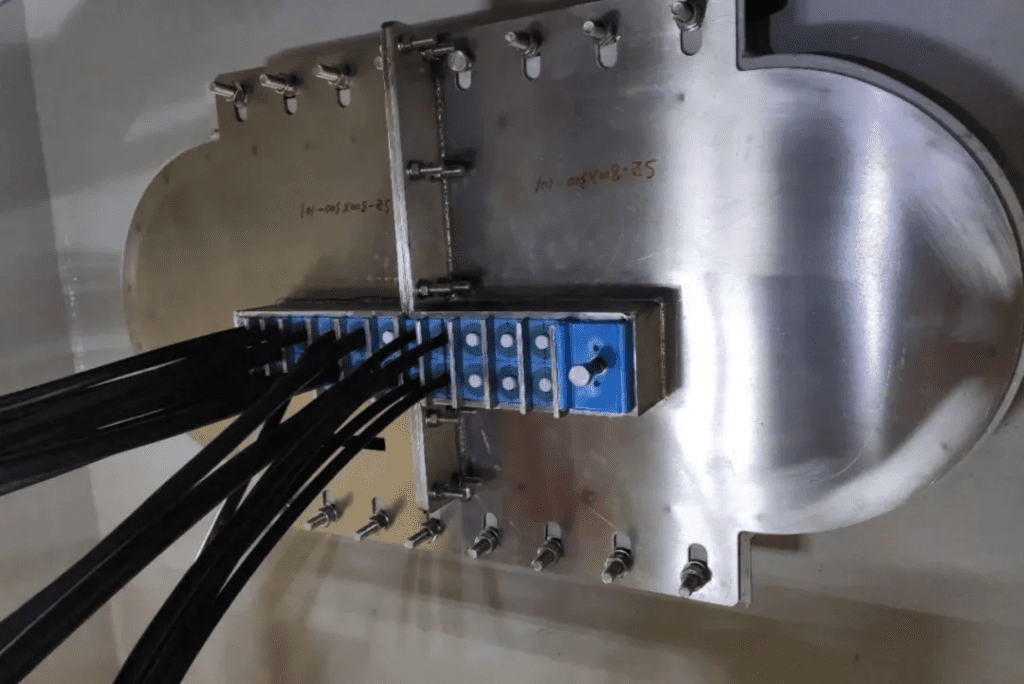

Application photos

TST CABLES modular cable and pipe penetration sealing system is like a fireproof guard for power stations. With its compact structure and high-performance sealing materials, it covers the cabinets with solid protective armor, effectively blocks the intrusion of moisture and dust, and ensures the normal operation of the equipment in harsh environments. The special design and materials cleverly alleviate the impact of unit vibration and reduce vibration transmission, just like a protective umbrella for precision instruments and sensors, ensuring the accuracy and reliability of monitoring data. The sealing system using polymer materials has excellent corrosion resistance and anti-aging properties, fearless of the challenges of high temperature, low temperature, corrosion and condensation, greatly extending the service life of the cabinets and reducing maintenance costs. Its modular design is a powerful assistant for optimizing internal wiring, making cable laying standardized and orderly. During maintenance, modular components can be quickly disassembled, easily inspected and maintained, reducing the difficulty of maintenance, reducing the frequency of shutdown maintenance, injecting a shot of adrenaline into the stable power generation of hydropower stations, and effectively promoting the stable operation of the power grid.

Petrochemical: A safety barrier to ensure production

In the petrochemical industry, cable and pipe sealing has always been a “big worry”. Although traditional sealing materials are easy to install and low-cost, they are often unable to cope with extreme environments such as high temperature, high pressure and corrosion.

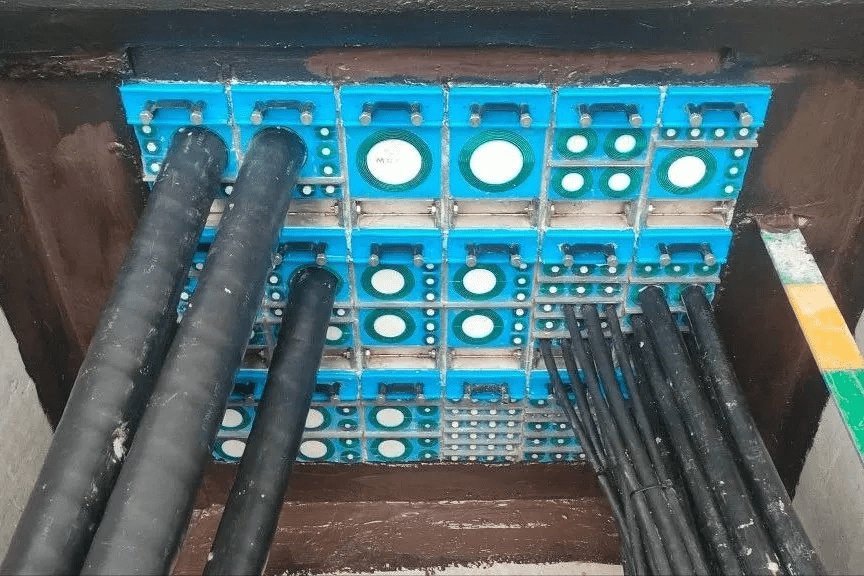

As a pioneer in the field of modular cable penetration sealing in China, TST CABLES has devoted itself to studying the sealing problems in the petrochemical industry and has created modular cable and pipe penetration sealing devices, which have been successfully applied to a new petrochemical project of a certain energy company in Hebei. It has built a “safety wall” for the cable penetration of the cabinet room, instrument control room and other building walls of the project, effectively isolating explosion shock waves, fire, smoke, toxic gases, radiation, chemicals, water, electromagnetic radiation and rodents, etc., to protect the safety of personnel and equipment.

After applying the sealing system, the company did not have any safety accidents caused by cable penetration sealing problems in subsequent production operations, the equipment failure rate was significantly reduced, and the production stability was greatly improved, laying a solid foundation for the company’s efficient and stable production.

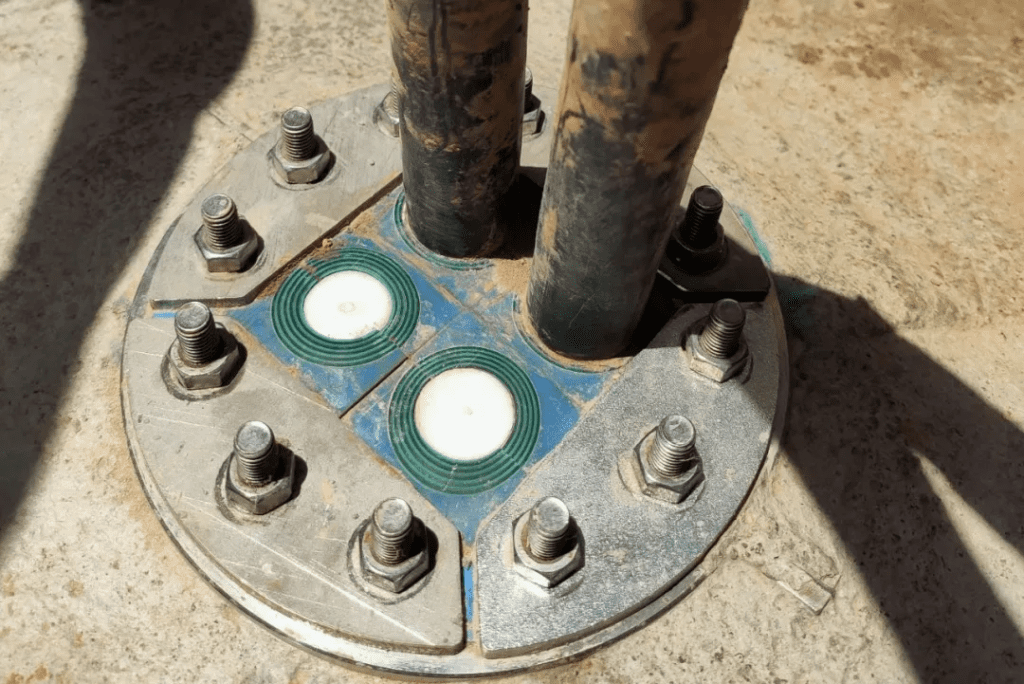

Real-life application photos

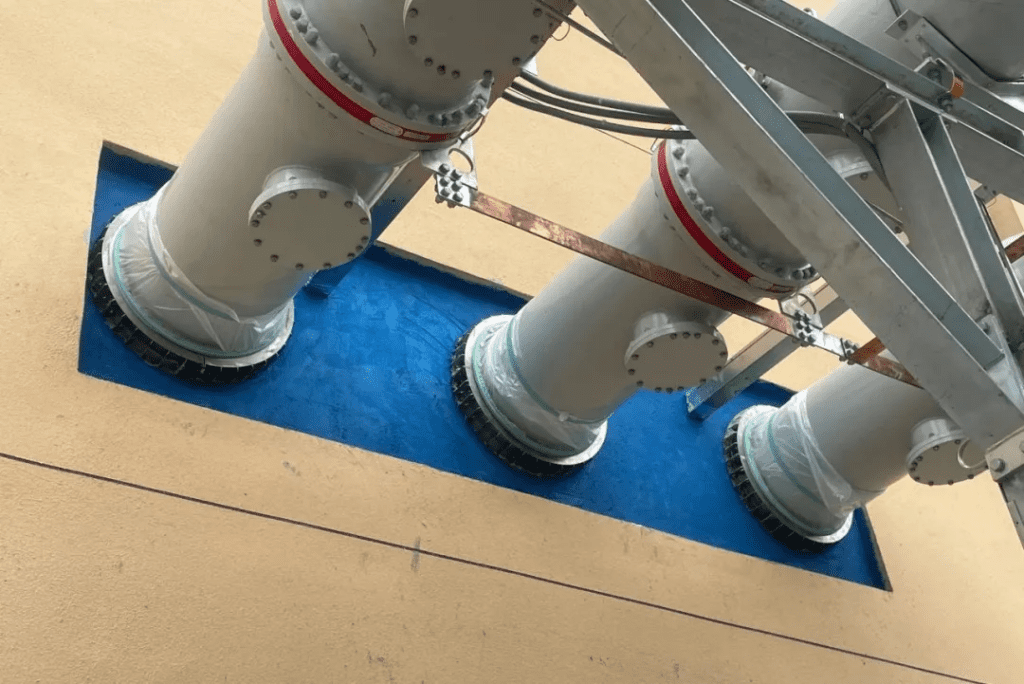

Offshore wind power: wind turbine safety line

The marine environment of offshore wind power platforms is extremely harsh, with high-salinity seawater, high-humidity air and strong ultraviolet rays, which are constantly “attacking” cables, pipelines and their sealing materials. Faced with difficult problems such as water vapor, salt spray, marine life, high temperature, explosive environment, electromagnetic interference, etc., TST CABLES modular cable and pipeline penetration and sealing systems rely on excellent innovative technology to protect offshore wind power platforms.

In a large offshore wind power project on the southeast coast of my country, TST CABLES modular cable and pipeline penetration and sealing systems successfully withstood the test of strong typhoons.

TST CABLES modular cable and pipeline penetration and sealing system system structure provides all-round protection for offshore booster stations, effectively preventing the spread of flames and buying precious time for personnel evacuation and fire fighting and rescue; at the same time, its tight overall structure makes it difficult for marine life to find “invasion” gaps, avoiding biological debris from damaging the sealing system. Its special electromagnetic shielding material and exquisite structural design are like putting an “electromagnetic shield” on the system, effectively blocking external electromagnetic interference, while preventing internal electromagnetic signal leakage, and ensuring the stable operation of power and communication systems.

The penetration parts where the TST CABLES cable and pipe sealing system is applied are sealed intact, without seawater leakage, cable short circuit and other problems, ensuring the continuous and stable operation of the wind power platform in extreme weather, and making great contributions to the reliable power supply of offshore wind power.

Real-life photos of the application

Railway transportation: peace of mind while speeding

Rail transit, as the “artery” of modern cities, is of vital importance for its safe and stable operation. Subways, high-speed railways and other rail vehicles shuttle underground, elevated or in the wild, and the operating environment is complex and changeable. Once a fire occurs, the enclosed space, dense personnel and limited evacuation channels will have disastrous consequences.

TST CABLES modular cable and pipe penetration sealing system is mainly used in key places such as bridge main box girder pipe holes, distribution rooms, shafts, fan rooms, pump rooms, and pump stations in the world-class cross-sea cluster project of the Shenzhen-Zhongshan Channel. It can effectively resist humid salt spray, flood mud, high temperature aging, salt spray corrosion, and can also withstand the test of vibration and rodent bites, ensuring that cables and pipes are well sealed when crossing, moisture, gas and harmful substances can enter seamlessly, and the power, communication and other systems operate stably, which will escort the smooth opening of the Shenzhen-Zhongshan Channel.

Real application photos

Looking back, the traditional cable and pipe penetration and sealing methods are full of drawbacks. Traditional materials are very easy to age, crack, and deform in harsh environments, such as high temperature, high humidity, and strong corrosion scenes, which greatly reduces the sealing performance; in terms of sealing performance, traditional sealing is difficult to take into account multiple requirements such as watertightness, airtightness, fireproofing, and explosion-proofing, and often loses one thing while taking another, which buries hidden dangers for safety.

In contrast, the TST CABLES modular cable and pipe penetration and sealing system is like a storm of innovation, completely subverting tradition. With excellent materials, exquisite design, and powerful performance, it comprehensively resolves the sealing problems of various industries, and shows incomparable advantages in many aspects such as ensuring safety, improving efficiency, reducing costs, and adapting to development.

If you want to learn more about the TST CABLES cable and pipe penetration and sealing system, please feel free to send us an email to communicate, and you can also get free samples.

Also available in:

English