Special wires and cables is a series of products with unique properties and special structure, equivalent to a large number of ordinary wires and cables, with higher technical content, use of more stringent conditions, smaller batches, higher value-added features, special cables are commonly used in the military market, the civilian market (petrochemical, metallurgical machinery, real estate and construction, information and communication, automotive industry, such as ships), oil platforms (deep-well survey cables, deep-well submerged oil pump cables, heating, temperature control and other multi-functional cables), civil aviation, etc., the development direction of diversification. Specialty cables are commonly used in military market, civilian market (petrochemical, metallurgical machinery, real estate and construction, information and communication, automobile and shipbuilding industries), oil platform (deep-well survey cable, deep-well submersible oil pump cable, heating self-control temperature and other multi-functional cables), civil aviation, and so on, with diversified development directions.

1、High temperature resistant cable

Aerospace, rolling stock, energy, iron and steel, non-ferrous metal smelting, oil mining, electrical machinery and other fields need to use high-temperature-resistant wires and cables. Long-term continuous operating temperature of 125 degrees, 135 degrees, 150 degrees, 180 degrees, 200 degrees, 250 degrees and more than 250 degrees of high-temperature resistant wire and cable, commonly used irradiated cross-linked polyolefin, silicone rubber, fluorine resin, polyimide, mica, magnesium oxide and other wires and cables. Now introduces two new high temperature wire and cable.

Polyethersulfone (PES) insulated wire and cable

With excellent heat resistance, physical and mechanical properties, electrical insulation properties, extrusion molding, especially with the continuous use at high temperatures and rapid changes in temperature environment can still maintain stable performance and other outstanding advantages: heat distortion temperature of 200-220 degrees, the continuous use of the temperature of 180-200 degrees, the UL temperature index of 180 degrees; can be resistant to hot water or steam at 150-160 degrees, at high temperatures It is not subject to the erosion of acid and alkali at high temperature.

Modulus of elasticity in -100-200 degrees almost unchanged, especially at 100 degrees above than any one thermoplastic resin is better; coefficient of linear expansion is small, and its temperature dependence is also small; non-toxicity, recognized by the U.S. FDA, but also in line with Japan’s Ministry of Health and Welfare Notice No. 434 and No. 178 requirements; self-extinguishing, do not add any flame retardant has an excellent flame-retardant properties, up to UL94V-150 degrees. It is self-extinguishing and has excellent flame retardancy without the addition of any flame retardant, and can reach UL94V-0 grade (0.46mm).

Polyether ether ketone (PEEK) insulated wire and cable

Polyether ether ketone is a super heat-resistant thermoplastic resin. Long-term continuous use temperature of 250 degrees, UL temperature index of 250 degrees, PEEK is a flexible resin, and good creep resistance, and self-extinguishing, without adding any flame retardant up to UL94V-1 level (thickness of 0.3mm), 94V-0 (thickness of 1.5mm), 94V-5 (thickness of 3.2mm) requirements.

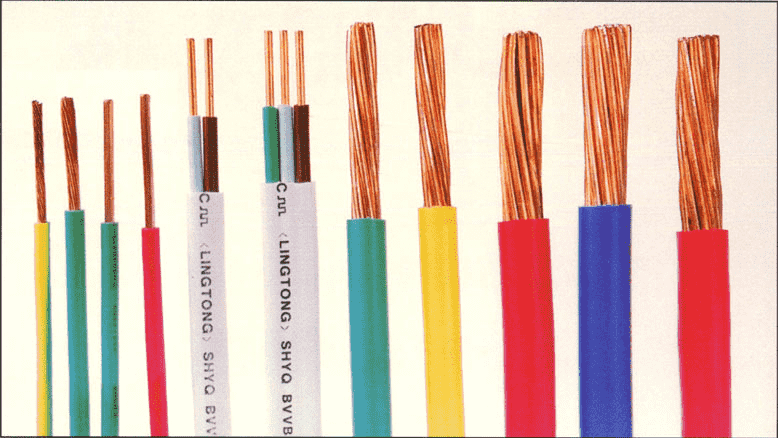

Picture

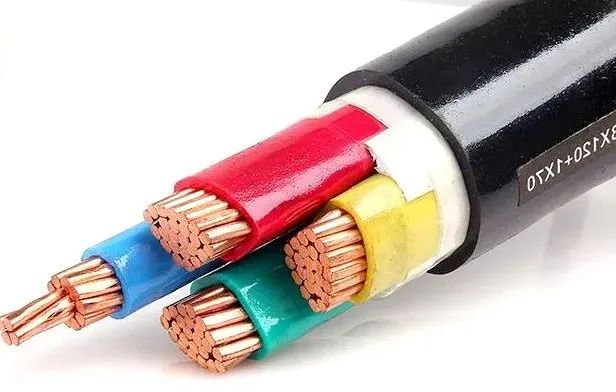

2、Cable with special purpose and structure

Low inductance cables

There is a difference between strong and weak power, and here we introduce a low inductance cable for strong power. This cable has a heat dissipation device, used for all kinds of contact welding machine, arc welding machine and pneumatic welding clamp connected between the new water-cooled low-sensitive cable, with a simple and reasonable structure, cooling water flow, will not form a blockage blocking and limiting the phenomenon of heat dissipation effect, long service life and other characteristics.

This new type of low-sensitivity cable also includes cable and cable ends with solidly mounted joints, and the cable is also composed of positive cable core and negative cable core installed in the outer hose. As such low-sensitivity cable is generally used for the voltage of 25-50V, the current in the 7000-12000A between the occasion, the cooling water in the cable short-circuit conductive phenomenon is basically negligible, so in this low-sensitivity cable does not use the isolation of the positive cable core and the negative cable core of the rubber hose, but only to set up a special cross-section of the spoke (commonly known as “) Plum blossom core” shape) of the core frame, its “wheel center” and adjacent “spokes” of the space enclosed between the direction of the axis that is the formation of longitudinal grooves, longitudinal grooves on the core frame and the cable is configured with the same number of the total number of positive cores, the cable is part of the positive cable core and the negative cable core. The cable is part of the positive cable core and negative cable core were resting on the core frame of the longitudinal grooves in the device outside the hose composition. Positive cable core and negative cable core of the two ends of the head were the same pole collection of bundles clamped in the core clamp, and then solidly mounted on the connector, the cable’s outer hose end of the head set in the connector at the end of the end of the section, and with a set of outside the hose outside of the tightening hoop tight sealing.

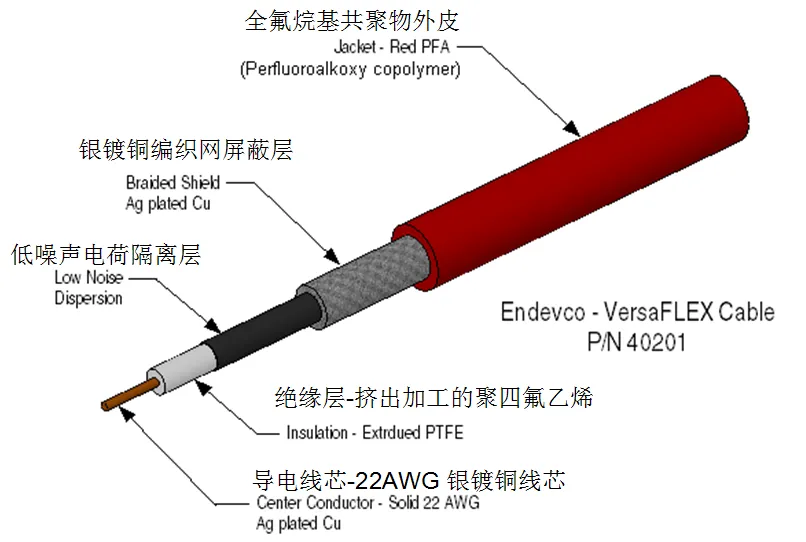

Low noise cable

Under the action of external factors such as bending, vibration, shock, and temperature change, the cable itself produces an impulse signal of less than 5mV, which is known as a low-noise cable, also known as shock-proof instrumentation cable. They are used for the measurement of tiny signals in many fields such as industry, medicine, and national defense. There are polyethylene insulated low-noise cables, F46 insulated low-noise cables, irradiation-resistant low-noise cables, low-capacitance low-noise cables, hydrophone cables, watertight low-noise cables, and other types and specifications of cables.

The causes of noise in cables are:

1) Molecular friction within the medium itself;

2) Changes in the capacitance of the cable;

3) The piezoelectric effect of the cable medium;

4) Charge generation by friction between the conductor and the medium in the cable, i.e., the separation of charge generated when the contact between the conductor and the insulation is broken.

In the polyethylene insulation surface extrusion of a thin layer of semi-conductive (thickness 0.20-0.30mm) of low-noise cables has been rapid development, the noise value of 2-3mV, for the work of 400 degrees of low-noise cables, can be solved by using high-temperature-resistant semiconducting fibers wrapped around the solution, and the noise can be up to 5mV.

3、Functionalized cable

Containing fluorine resin self-control stabilized 135 degrees heating cable

Self-controlling and stabilizing 135 degree heating cable composed of polyvinylidene fluoride (PVDF)/fluoroelastomer alloy/carbon black multi-complex. Its thermal range is different, showing different degrees of PTC conductive properties and conductive stability, which is due to the degree of crystallization of the substrate and crystalline morphology by different cooling speeds affect the insulation.

Electroluminescent wire and cable

Electroluminescent wires are the latest products in the field of international luminescent display, similar in appearance to ordinary wires and cables, the surface layer of the colored fluorescent plastic casing, which works continuously without any heat radiation, power consumption of only 50-60 for the LED lights, for the 20-30 string lights, neon lamps 1-5. such products are widely used to create energy-saving, environmentally friendly, healthy display of the lighting of a new era, with the following characteristics With the following features:

(1) light-emitting delicate and soft, bright colors, three-dimensional and a strong sense of perspective, suitable for night visual inspection.

2)Energy-saving, environmental protection and safety; the product has low power consumption and a wide range of applicable voltage. The use and abandonment will not produce any environmental pollution, and at the same time will not be dangerous to the human body.

(3) Soft, foldable and bendable, can be knotted, cut and spliced at will without affecting the light-emitting properties, easy and quick to use, installation without professional guidance.

(4) for the continuity of light-emitting devices, at the same time can be controlled according to the phone and match the actual types of dynamic multi-color flashing.

(5) Can be directly fixed on the surface of decorative objects using transparent tape, glue, pins, nails and so on.

Picture

4、New green insulated environmentally friendly cable

CMP cable

Can pass the UL highest flame retardant grade standard cable, for CMP cable. in the ordinary cable outside the extrusion of a thin layer of FEP (i.e., F46) sheath that can meet this requirement. Generally speaking, low-smoke halogen-free base material is polyolefin, which has a high fuel heat, is highly combustible, so they have to be mixed with metal hydrate filler to inhibit its flammability, but the role of hydration after the exhaustion of water, will cause fierce combustion, and FEP’s heat of combustion is very small, do not burn in case of fire.

Also available in:

English