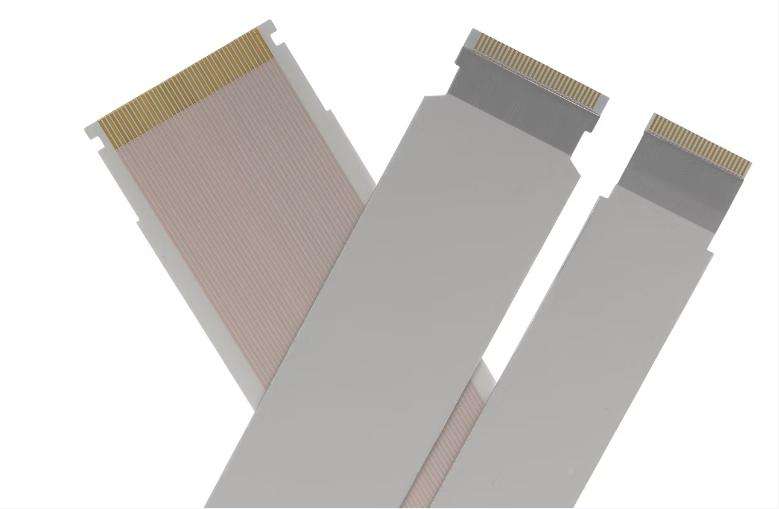

Silicone cable is a special type of cable, its main features and composition are as follows:

First, the main raw materials

Silicone cable mainly adopts two-component plus molding silicone as the main raw material.

Second, the structure and composition

Silicone cable usually includes the outer wrapping layer of the cable and the inner filling material, which are made of silicone. In addition, its main conductor often uses tinned copper wire, and the braid layer may use glass fiber and silicone resin.

Third, the characteristics and performance

- High temperature resistance: Silicone cables are able to work stably at temperatures up to 200°C while maintaining good electrical conductivity and insulation. It can work normally and stably between 60℃ and 200℃, and can even be used continuously for more than 10,000 hours when it reaches 200℃.

- Excellent weather resistance: Silicone cables have excellent weather resistance to extreme environmental conditions such as low temperature, high humidity and UV exposure.

- Superior electrical properties: The electrical properties of silicone cables include low dielectric constant, low dielectric loss, high insulation resistance and stable electrical signal transmission.

- Corrosion resistance: Silicone cables have good resistance to acids, alkalis, solvents and other chemicals.

- Good flexibility: silicone cable has good flexibility, easy to bend and install, suitable for a variety of irregular arrangement of places.

Fourth, the field of application

Due to the unique properties of silicone cable, it has a wide range of applications in many fields, including but not limited to:

- Electric power industry: used in transmission and transformation stations, power plants and other power equipment connection and distribution system.

- Electronics industry: It is widely used in the production process of electronic products, such as the connection of electronic components, wiring of test equipment, etc.

- Communication industry: it can be used in the connection line of communication equipment, such as high-speed transmission cable, Internet server, etc.

- Industrial field: it is suitable for high temperature process and harsh environment of industrial equipment, such as petrochemical industry, iron and steel smelting.

- Aerospace field: Silicone cable is also widely used in the electrical system of aircraft and spacecraft because of its high temperature resistance, impact resistance and other characteristics.

Fifth, the difference between silicone cable and PVC cable

Material composition:

Silicone cable: the use of silicone rubber as insulation and outer sheath material.

PVC cable: the use of polyvinyl chloride (PVC) as an insulating material and outer sheath material.

Temperature resistance:

Silicone cables: have high temperature resistance and can usually be used in temperatures ranging from -50°C to 180°C (and even higher up to 200°C).

PVC cables: have relatively low temperature resistance and are typically used in temperatures ranging from -15°C to 70°C.

Corrosion resistance:

Silicone cables: have good corrosion resistance to some chemicals, such as acids, alkalis, solvents and so on.

PVC cable: has relatively poor corrosion resistance to some chemicals and is more susceptible to damage by chemicals.

Fire resistance:

Silicone cable: has better fire resistance, can maintain insulation effect for a longer time in the fire.

PVC cable: relatively poor fire resistance, easy to burn in a fire, but has a certain flame retardancy, which can reduce the risk of fire.

Elasticity and flexibility:

Silicone cable: has good flexibility and elasticity, easy to bend and install, suitable for irregularly arranged places.

PVC cable: also has a certain degree of flexibility and elasticity, but compared to silicone cable is more rigid.

Cost:

Silicone cable: higher cost.

PVC cables: lower cost, with a high cost performance ratio.

Application areas:

Silicone cable: widely used in electronics, electric power, aerospace and other industries due to its high temperature resistance, weather resistance and other characteristics, especially in the high temperature environment of the equipment wiring.

PVC cable: suitable for wiring in general working conditions, such as household appliances, lighting equipment, computer connecting lines and other power transmission, in ordinary indoor applications can meet the requirements.

Six, silicone cable flame retardant grade

Silicone cable flame retardant rating is mainly based on UL94 standard for classification, the standard developed by the Underwriters Laboratories (UL).

The following is the classification and characteristics of silicone cable flame retardant grade:

- Class V-0: This is the highest flame retardant class in silicone cables. It indicates that the cable will not spontaneously combust within 30 seconds in a vertical combustion test and that the burning drippings will not ignite the cotton pads below. In addition, the flame generated when the cable burns spreads very slowly and can self-extinguish in a very short period of time. v-0 silicone cables are usually used in applications requiring high fire resistance, such as high-temperature electrical equipment, industrial furnaces, and so on.

- Class V-1: In the vertical combustion test, the burning time of this class of cable will not exceed 30 seconds, and the flame will not spread more than 25 centimeters in the vertical direction. At the same time, the cable will not produce burning droplets in the combustion process to ignite the cotton pads below. v-1 silicone cables are suitable for some of the fire performance requirements of certain occasions.

- Class V-2: This is the lower flame retardant class of silicone cables. In a vertical combustion test, the cable will also not burn for more than 30 seconds, but the flame may spread a little farther than in class V-1. Compared to V-0 and V-1, V-2 silicone cables are slightly less flame retardant, but still have some fire resistance.

TST CABLES reminds consumers to be aware that silicone cables from different manufacturers may have different flame retardant properties and qualities. The flame retardant rating of silicone cables is an important indicator of their fire performance. When choosing silicone cables, the appropriate flame retardant rating should be selected according to specific application scenarios and fire protection requirements. When choosing silicone cables, in addition to considering the flame retardant rating, you also need to pay attention to factors such as the manufacturer of the cable, the quality of the material and the environment in which it is used.

For more information on low-smoke, halogen-free, flame-retardant, high-temperature-resistant cables,Silicone cableor to customize cables for your machinery or system, visit https://www.tstcables.com/contact-us/

or send an e-mail to:lixiangchao@testeck.com.

Also available in:

English