Features of High Temperature Cable Silicone Cable:

The main features of silicone cables are high temperature resistance, insulation, flame retardant, acid and alkali resistance, aging resistance, weather resistance, high strength, high modulus, anti-static, and smooth appearance. There are many kinds of them, such as fluoroplastic insulated high-temperature wire, silicone rubber insulated high-temperature wire, high-temperature electronic wire, silicone rubber insulated braided wire, multi-core high-temperature cable, PEEK wire, and mineral insulated fire-resistant cable. Silicone rubber high voltage wire, PTFE high voltage wire and PTFE wire, nylon sheathed wire, mica high temperature wire, and aircraft waxed wire.

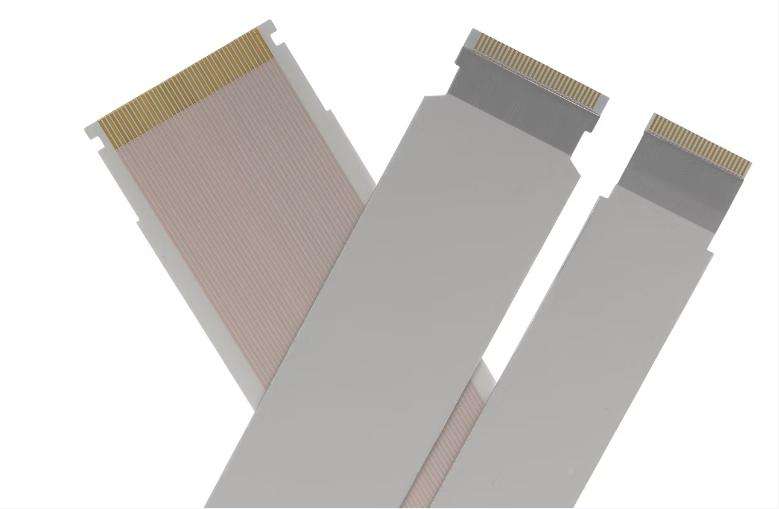

The quality of silicone cables can be seen at a glance from the appearance of the wires and cables. The appearance of silicone high temperature wire is required to be smooth and round, even and uniform luster, no visible debris, no mechanical damage, no flattening, no deviation from the core (not exceeding the specified deviation, bubble trachoma, bamboo, twisted shape, obvious particles and so on. As can be seen, the thickness of the sheath has a certain impact on the quality of silicone high temperature wire. Of course, the thickness of the sheath does not meet the standard, if the thickness exceeds the standard, also does not meet the standard.

The material performance of silicone cable is not reflected by the thickness, but according to the standard requirements. If a certain index fails to meet the standard, it will directly affect the quality of silicone high temperature wire. After the silicone high temperature cable is laid, it will be energized for a long time and generate heat. The allowable working temperature of the conductor is 70, and the allowable long-term working temperature of the silicone high-temperature wire is 180. in summer, the working temperature will rise. These temperatures will be dissipated through the outer jacket. The thickness of the sheath will increase and it will be difficult to dissipate the heat, which will affect the service life of the silicone high temperature wire. Under the action of heat, the insulation layer will undergo a series of physical and chemical changes, losing its original excellent performance, resulting in a significant decline in insulation performance, or even short circuit, affecting the normal operation of the unit.

Silicone cable (PVC wire) general temperature range of -15 ~ 80, and silicone high-temperature wire up to -60 ~ 200. PVC wire life is short, generally about two years, poor flexibility, poor aging resistance, easy to crack in the sun, suitable for indoor lamps and household appliances. Polyvinyl chloride wire is harder, with smooth surface and high brightness. The cost of PVC wire of the same specification is much lower than silicone high temperature wire, the compressive strength is lower than silicone wire, and the bending recovery ability of PVC wire is poor. Once bent and folded, it is very difficult to return to its original form. However, silicone high temperature wire has drawbacks, such as poor tear resistance of the jacket and high manufacturing costs.

High Temperature Cable Silicone cable shopping guide:

- Define the use environment and requirements: first of all, define the use environment of the silicone cable, such as temperature range, humidity, chemical corrosion and so on. At the same time, understand the cable’s rated voltage, current load and other requirements, in order to choose the appropriate cable specifications and types.

- Check the appearance and quality of the cable: high-quality silicone cables should have a smooth, rounded, glossy and uniform appearance, with no visible debris, mechanical damage, flattening, deviation from the core and other defects. In addition, the thickness of the cable’s sheath should be in accordance with the standard, too thick or too thin may affect the performance of the cable.

- Concerned about the high temperature resistance of the cable: the high temperature resistance of the silicone cable is one of its important features. When shopping, make sure that the cable can withstand the required operating temperature range to avoid damage to the cable due to high temperature.

- Consider the electrical insulation performance of the cable: electrical insulation performance is a key indicator of the safety of the cable. When selecting, choose silicone cables with good electrical insulation performance to ensure electrical safety.

- Pay attention to the flexibility and bending performance of the cable: silicone cables usually have better flexibility and bending performance to adapt to different wiring needs. When shopping, you can pay attention to the minimum bending radius of the cable and other parameters to ensure that it can meet the actual use requirements.

- Check the certification and standards of the cable: when shopping for silicone cables, you should check whether the cable meets the relevant certification standards, such as ROHS certification, UL certification and so on. These certifications can ensure that the cable meets the relevant requirements and improve the safety of use.

- Choose reputable brands and suppliers: Choosing brands and suppliers with good reputation and word-of-mouth can ensure the quality and after-sales service of the cables. When purchasing, you can find out the supplier’s qualification, production experience and customer evaluation and other information.

TST CABLES engineers’ suggestion:

When purchasing silicone cables, you need to consider many factors such as the usage environment, appearance quality, high temperature resistance, electrical insulation performance, flexibility and bending performance as well as certification standards. Through careful comparison and selection, you can find the most suitable silicone cable products for your needs. If you need high quality silicone cables, please contact TST CABLES.

TST CABLES silicone cable, excellent quality, safe and reliable! TST CABLES choose high-quality silicone, high and low temperature resistance, aging, to adapt to a variety of environments. Excellent electrical insulation performance, to protect electrical safety. Soft and easy to bend, convenient wiring. Strictly follow the certification standards, quality is guaranteed. Whether for industrial equipment or household appliances, our silicone cables are your ideal choice. Choose TST CABLES silicone cable to make your equipment run more stable, safe and efficient!

TST CABLES–Specializing in high temperature resistant cable applications and solutions

Fluoroplastic Cables|Polyimide (PI) Cables|Polyetheretherketone (PEEK) Cables|Silicone Rubber Cables

Rail way | Aviation | Marine | Nuclear | Oil & Gas | Wind Power industry applications

For more information on low-smoke, halogen-free, flame-retardant, high-temperature-resistant cables or to customize cables for your machinery or system, visit https://www.tstcables.com/contact-us/

or send an e-mail to:lixiangchao@testeck.com.

Also available in:

English