First, the characteristics of silicone wire cable

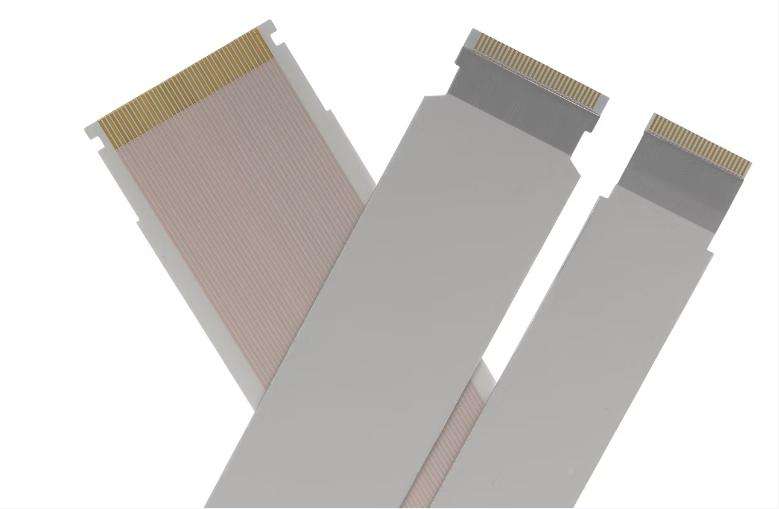

Silicone wire is a high-temperature, weather-resistant, aging-resistant, good insulation properties of the wire, widely used in electronics, electrical, instruments, meters, machinery and other fields. Its insulation and sheath are made of silicone rubber, so it has high temperature resistance.

Second, the oil resistance of silicone wire cable

Silicone wire as a special wire, has a strong oil resistance, can work without the influence of oil. However, it depends on its material and hardness and other parameters. When choosing silicone cable, you should choose different materials and hardness of silicone cable according to different use environment to ensure its normal use.

Third, the selection of the number of silicone cable cores to consider:

- Load demand assessment: first of all, it is necessary to clarify the load demand of the cable, including parameters such as current, voltage and power. According to these parameters, the required cross-sectional area and number of cores can be calculated to ensure that the cable can safely and effectively transmit power.

- Signal Transmission Requirements: If the cable is mainly used for signal transmission, then factors such as the type of signal, transmission speed, and interference immunity need to be considered. Different signaling requirements may require different numbers and configurations of cores.

- Installation space limitations: When selecting the number of cores, the installation space of the cable needs to be considered. Too many cores may lead to an increase in the size of the cable, making it difficult to install in a limited space. Therefore, the number of cores and cable size need to be weighed against the actual situation.

- Cost factor: An increase in the number of cores usually means an increase in the cost of the cable. Therefore, when choosing the number of cores, you need to consider the relationship between performance and cost to find the most suitable balance for the actual needs.

- Safety considerations: Too many cores may lead to excessive stress on the cable during bending or installation, increasing the risk of damage to the cable. Therefore, when choosing the number of cores, you need to ensure that the structural design and manufacturing process of the cable can meet the safety requirements.

- Follow standards and specifications: When selecting the number of cores for silicone cables, relevant cable standards and specifications should be followed to ensure cable compliance and reliability.

The selection of the number of silicone cable cores needs to take into account a number of factors such as load requirements, signal transmission requirements, installation space, cost, safety, and standards and specifications, etc. TST CABLES suggests consulting with our professional engineers during the actual selection process in order to obtain more accurate selection advice and guidance.

Fourth, the use of silicone wire precautions

- The temperature range of silicone wire should be between -60℃ and +200℃.

- When using silicone wire, care should be taken to avoid mechanical damage and puncture.

- Silicone wires should not be in direct contact with polymer materials.

- Silicone wire should not be in prolonged contact with alkaline materials such as calcium hydroxide, potassium hydroxide and sodium hydroxide.

- During the use of silicone wire, it should be installed and used correctly according to the requirements in the product specification.

In summary, silicone wire has strong oil resistance, but when using it, you should pay attention to choosing the right material and hardness, and comply with the precautions for the use of silicone wire to ensure its normal use.

TST CABLES silicone cable, excellent quality, safe and reliable! TST CABLES choose high-quality silicone, high and low temperature resistance, aging, to adapt to a variety of environments. Excellent electrical insulation performance, to protect electrical safety. Soft and easy to bend, convenient wiring. Strictly follow the certification standards, quality is guaranteed. Whether for industrial equipment or household appliances, our silicone cables are your ideal choice. Choose TST CABLES silicone cable to make your equipment run more stable, safe and efficient!

TST CABLES–Specializing in high temperature resistant cable applications and solutions

Fluoroplastic Cables|Polyimide (PI) Cables|Polyetheretherketone (PEEK) Cables|Silicone Rubber Cables

Rail way | Aviation | Marine | Nuclear | Oil & Gas | Wind Power industry applications

For more information on low-smoke, halogen-free, flame-retardant, high-temperature-resistant cables or to customize cables for your machinery or system, visit https://www.tstcables.com/contact-us/

or send an e-mail to:lixiangchao@testeck.com.

Also available in:

English