Fire Prevention

Water Tight

- Airtight

Dustproof

Noise Reduction

- EMI/EMP

- Home

- /

- Modular based sealing system|Sealing...

TST Sealing System

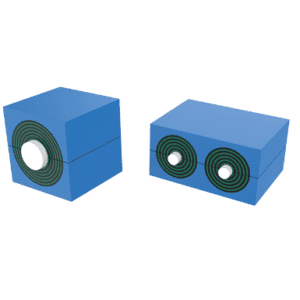

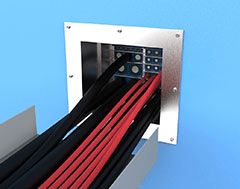

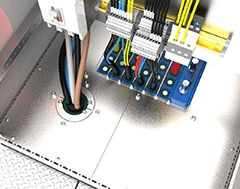

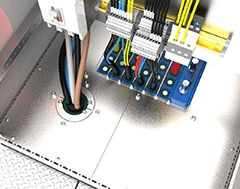

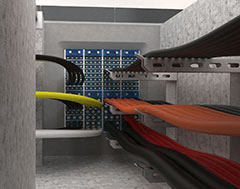

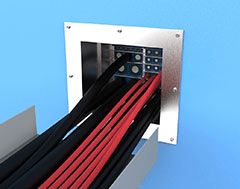

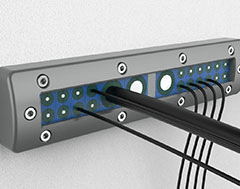

New fireproof plugging materials have made many improvements on the basis of traditional materials, such as modular cable/pipe sealing systems, which have significant advantages in fireproof performance, environmental protection, construction convenience and comprehensive cost, and gradually replaced traditional plugging materials.

Infrastructure construction & Industrial Manufacturing

TST Verification Case

Laboratory

Vault

Pipeline Gallery

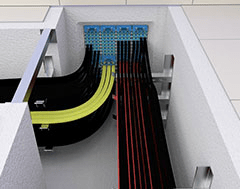

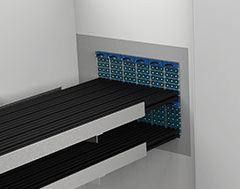

Data Center

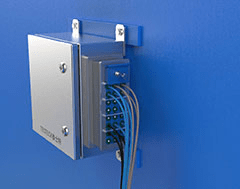

TST cable & pipe penetration sealing system (MCT) is used in pipe corridors, biological laboratories, data centers, airports, industrial installations, mechanical equipment, etc. It can seal cables and pipes conveniently and effectively, prevent fire, and resist multiple risks such as water, gas and rodents.

Sealing requirements:

- Fireproof

- Watertight

- Airtight

- Dustproof

- Noise reduction

- EMI/EMP

- Anti-pest and rodent

- Cable fixing

- Shock absorption

- Pressure resistance

- Corrosion resistance

Solution of TST Sealing System

Certified cable and duct sealing solutions:

- Flexible for different cable and duct sizes

- Built-in spare capacity, easy installation, easy upgrade and retrofit EMC solutions for electrical safety

- Explosion-proof solutions for hazardous areas

- Solutions for cable glands

- Non-welding solutions available for fresh water, chilled water and waste water pipes

Marine Engineering

TST Verification Case

Drilling platform

Booster station

FPSO

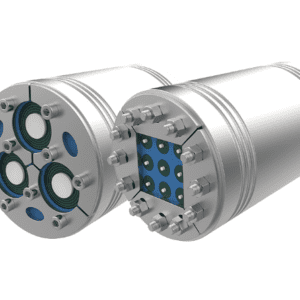

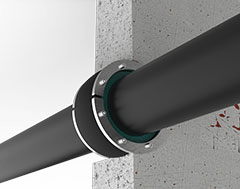

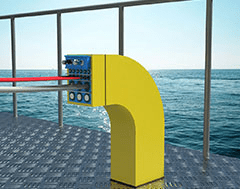

TST multi-cable/pipe penetration sealing system applied to offshore engineering can reduce the risks of fire, explosion, severe weather and other operational hazards, protect equipment and ensure operational performance and reliability.

Sealing requirements:

- Fireproof

- Watertight

- Airtight

- Dustproof

- Noise reduction

- EMI/EMP

- Anti-pest and rodent

- Cable fixing

- Shock absorption

- Pressure resistance

- Corrosion resistance

Solution of TST Sealing System

Certified cable and duct sealing solutions:

- Flexible for different cable and duct sizes

- Built-in spare capacity, easy installation, easy upgrade and retrofit EMC solutions for electrical safety

- Explosion-proof solutions for hazardous areas

- Solutions for cable glands

- Non-welding solutions available for fresh water, chilled water and waste water pipes

Shipbuilding

TST Verification Case

Civilian ships

Military ships

Shipbuilding companies, EPCs, design institutes and owners around the world can use Tester cable/pipe transit sealing systems to solve cable and pipe sealing problems in various complex working conditions in various parts of the hull. A complete set of test reports and industry qualifications can be provided to ensure safety and operational reliability.

Sealing requirements:

- Fireproof

- Watertight

- Airtight

- Dustproof

- Noise reduction

- EMI/EMP

- Anti-pest and rodent

- Cable fixing

- Shock absorption

- Pressure resistance

- Corrosion resistance

Solution of TST Sealing System

Certified cable and duct sealing solutions:

- Flexible for different cable and duct sizes

- Built-in spare capacity, easy installation, easy upgrade and retrofit EMC solutions for electrical safety

- Explosion-proof solutions for hazardous areas

- Solutions for cable glands

- Non-welding solutions available for fresh water, chilled water and waste water pipes

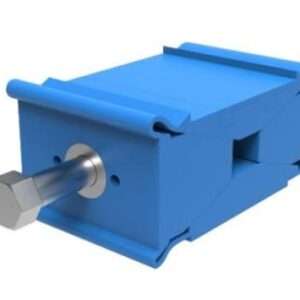

Power Engineering

TST Verification Case

Wind power generation

Hydropower generation

Photovoltaic power generation

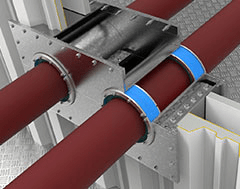

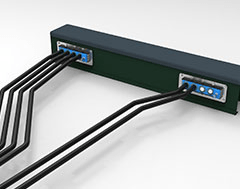

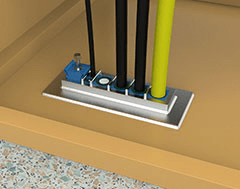

TST provides a complete set of safe and efficient cable/pipe penetration sealing solutions that simplify design, deployment, production and maintenance. They are used in all important areas of the global power energy supply industry to effectively utilize space and minimize the risk of downtime caused by animals, water and dust.

Sealing requirements:

- Fireproof

- Watertight

- Airtight

- Dustproof

- Noise reduction

- EMI/EMP

- Anti-pest and rodent

- Cable fixing

- Shock absorption

- Pressure resistance

- Corrosion resistance

Solution of TST Sealing System

Certified cable and duct sealing solutions:

- Flexible for different cable and duct sizes

- Built-in spare capacity, easy installation, easy upgrade and retrofit EMC solutions for electrical safety

- Explosion-proof solutions for hazardous areas

- Solutions for cable glands

- Non-welding solutions available for fresh water, chilled water and waste water pipes

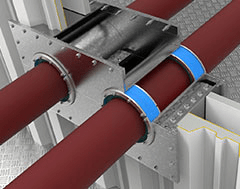

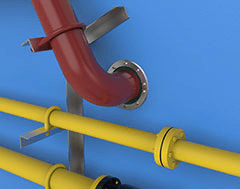

Petrochemical

TST Verification Case

Oil

Natural Gas

Chemicals

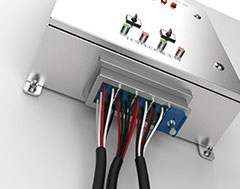

TST cable/pipe penetration sealing system is widely used in harsh and hazardous places in many fields such as energy and chemical industry due to its excellent flexibility. The system effectively prevents multiple potential risks in buildings, sites and cabinets, especially in dangerous occasions and harsh environments, showing excellent protection performance to ensure the safety of life and property.

Sealing requirements:

- Fireproof

- Watertight

- Airtight

- Dustproof

- Noise reduction

- EMI/EMP

- Anti-pest and rodent

- Cable fixing

- Shock absorption

- Pressure resistance

- Corrosion resistance

Solution of TST Sealing System

Marine Engineering

TST Verification Case

Drilling platform

Booster station

FPSO

TST multi-cable/pipe penetration sealing system applied to offshore engineering can reduce the risks of fire, explosion, severe weather and other operational hazards, protect equipment and ensure operational performance and reliability.

Sealing requirements:

- Fireproof

- Watertight

- Airtight

- Dustproof

- Noise reduction

- EMI/EMP

- Anti-pest and rodent

- Cable fixing

- Shock absorption

- Pressure resistance

- Corrosion resistance

Solution of TST Sealing System

Certified cable and duct sealing solutions:

- Flexible for different cable and duct sizes

- Built-in spare capacity, easy installation, easy upgrade and retrofit EMC solutions for electrical safety

- Explosion-proof solutions for hazardous areas

- Solutions for cable glands

- Non-welding solutions available for fresh water, chilled water and waste water pipes

Certified cable and duct sealing solutions:

- Flexible for different cable and duct sizes

- Built-in spare capacity, easy installation, easy upgrade and retrofit EMC solutions for electrical safety

- Explosion-proof solutions for hazardous areas

- Solutions for cable glands

- Non-welding solutions available for fresh water, chilled water and waste water pipes

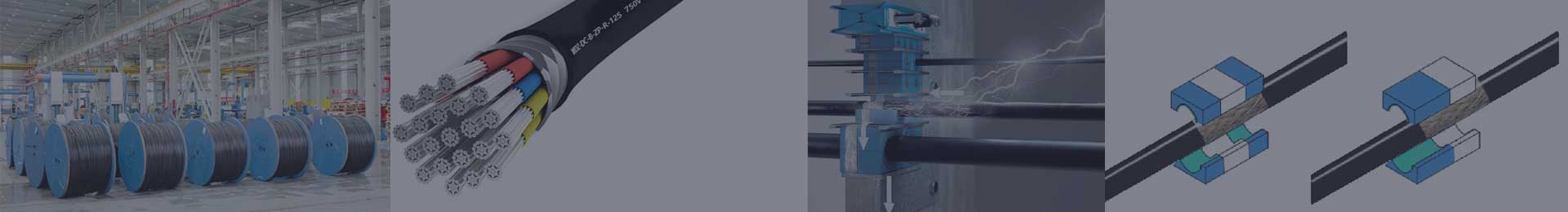

Railway System

TST Verification Case

High-speed rail

Subway

Light rail

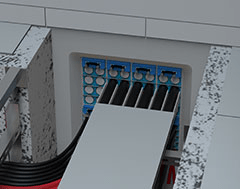

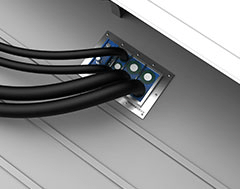

TST certified cable/pipe penetration sealing systems can meet the sealing needs of various complex working conditions (inside the vehicle, outside the vehicle and facilities along the vehicle), can withstand multiple threats such as fire, smoke, water, air impact and vibration, and provide unique solutions with cable stability.

Sealing requirements:

- Fireproof

- Watertight

- Airtight

- Dustproof

- Noise reduction

- EMI/EMP

- Anti-pest and rodent

- Cable fixing

- Shock absorption

- Pressure resistance

- Corrosion resistance

Solution of TST Sealing System

Certified cable and duct sealing solutions:

- Flexible for different cable and duct sizes

- Built-in spare capacity, easy installation, easy upgrade and retrofit EMC solutions for electrical safety

- Explosion-proof solutions for hazardous areas

- Solutions for cable glands

- Non-welding solutions available for fresh water, chilled water and waste water pipes

Related by TST:

How to choose lszh cable railway cable subway fireproof soft cable

Subway fireproof soft cable is a cable designed to meet...

Read MoreDenmark cable Power Cable Denmark High Voltage Cable Solutions

As a Nordic country, Denmark enjoys a high reputation in...

Read More-200℃-+1200℃ Low smoke halogen free flame retardant PEEK cable Aircraft Cable

PEEK cable has super strong mechanical properties, good toughness and...

Read MoreApplication of low smoke zero halogen flame retardant cable(LSOH cable)in EMU

When the EMU shuttles across the vast land, it is...

Read MoreAlso available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese

Portuguese (Brazil)