600V to 25kV XLPE-LSFH (cross-linked polyethylene – low smoke zero halogen) cable is a cable specially designed for use in application scenarios that require high electrical performance, environmental protection characteristics and safety standards. This type of cable combines the advantages of XLPE as an insulation material and the characteristics of LSFH sheath material, and is suitable for power transmission and distribution under a variety of environmental conditions.

600V to 25kV XLPE-LSFH Cable Main Features

Cross-linked polyethylene (XLPE) insulation:

High electrical performance: XLPE has excellent electrical insulation properties, can withstand higher voltage levels (from 600V to 25kV), and has good dielectric strength.

Temperature resistance: XLPE is able to remain stable over a wide operating temperature range, typically operating in the range of -40°C to +90°C, and up to +250°C in short circuits.

Anti-aging: Due to its chemical structure, XLPE is not easy to age and has a long service life.

Low Smoke Zero Halogen (LSFH) Sheath:

Environmental Protection and Safety: In the event of a fire, LSFH materials release very little smoke and do not contain halogens, which means that no toxic or corrosive gases are produced, which is conducive to the evacuation of personnel and reduces damage to equipment.

Mechanical Protection: LSFH sheath provides good physical protection against wear and other physical damage in daily use.

Adaptability:

This cable is suitable for indoor and outdoor installation, especially for places with strict environmental protection requirements, such as public buildings, hospitals, schools, subways, etc.

It can be used for fixed laying, or it can be selected according to specific needs whether it has flame retardant or fire resistant properties.

Application Fields of 600V to 25kV XLPE-LSFH Cables

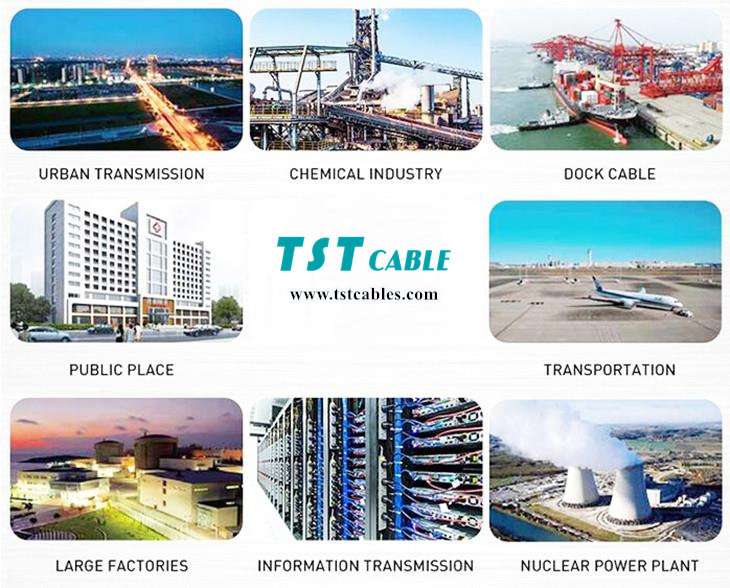

Industrial Facilities: Including factories, mines and other places where high-voltage power transmission is required.

Commercial Buildings: Power distribution systems in large buildings such as office buildings and shopping malls.

Public Transportation: Power supply for rail transportation systems such as subways and railways.

Energy Industry: Grid access for new energy projects such as wind farms and solar power stations.

Data Center: Provide reliable power supply while meeting strict fire safety standards.

Standards and Certifications

This type of cable usually needs to comply with relevant international or national standards, such as IEC 60502, EN 50521 or other application-specific standards. In addition, in some regions, it may be necessary to pass local certification by the authority, such as Russian Maritime Registration Society type approval and factory approval if the target market is Russia or follows Russian standards.

Application requirements for 600V to 25kV XLPE-LSFH cables

- Voltage level matching: Make sure that the rated voltage of the selected cable matches the operating voltage in the actual application. For application scenarios with different voltage levels (such as 600V, 3.3kV, 6.6kV, 11kV, 22kV, etc.), it is necessary to select cables of corresponding specifications to ensure safe operation.

- Environmental adaptability: Considering the specific environmental conditions (temperature, humidity, chemical exposure, etc.) where the cable will be deployed, select XLPE-LSFH cables with appropriate protective characteristics. For example, additional sheath material protection may be required in corrosive environments.

- Fire resistance: In places with strict fire protection requirements, such as underground tunnels and high-rise buildings, XLPE-LSFH cables with excellent flame retardant properties should be selected, and whether specific fire resistance standards need to be met should be considered.

600V to 25kV XLPE-LSFH cable installation precautions

- Bending radius: Pay attention to the minimum bending radius of the cable during installation to avoid excessive bending that may damage the insulation layer. Generally speaking, the bending radius should not be less than 10 to 20 times the outer diameter of the cable, and the specific value depends on the specific model of the cable and the manufacturer’s recommendations.

- Tensile strength: Pay attention to controlling the tension during laying to prevent damage to the internal structure of the cable due to excessive stretching. Normally, the maximum allowable tension should be clearly stated in the product manual.

- Joint handling: It is crucial to properly handle cable joints. Appropriate connectors must be used and sealed in accordance with specifications to prevent moisture intrusion and electrical failures.

- Grounding design: Reasonably plan the grounding scheme of the cable system to ensure personal safety and normal operation of equipment. Especially in high-voltage systems, good grounding can effectively reduce electromagnetic interference and the risk of electric shock.

600V to 25kV XLPE-LSFH cable maintenance

- Regular inspection: Regularly inspect the installed cable system, especially those parts in harsh environments, such as checking for external damage, signs of aging, or loose joints.

- Cleaning and anti-corrosion: Keep the cable surface clean and clean dust, oil and other pollutants in time; for exposed metal parts, take necessary anti-corrosion measures to extend the service life.

- Testing and evaluation: Use professional equipment to test the electrical performance of the cable, including insulation resistance measurement, partial discharge detection, etc., so as to detect problems early and repair them in time.

- Documentation: Establish a complete maintenance file to record the results of each inspection and any maintenance activities, which will help track the trend of cable status changes and optimize subsequent management strategies.

600V to 25kV XLPE-LSFH cables have become an indispensable part of modern power transmission and distribution systems due to their excellent safety, environmental protection and electrical performance. Choosing the right cable type is essential to ensure the safety, reliability and efficiency of the system.

Through the above detailed application requirements, installation instructions and maintenance recommendations, the advantages of 600V to 25kV XLPE-LSFH cables can be maximized to ensure the safety and reliability of power transmission while extending the service life of the cables. Whether it is a new project or an upgrade of an existing facility, it is crucial to choose the right cable type and follow the correct operating procedures. If you need 600V to 25kV XLPE-LSFH cables, please email us and get free samples.

Also available in:

English