UL3645 6-30AWG high temperature coaxial cable silicone wires

This is a high temperature coaxial cable that complies with UL3645 and has excellent high-temperature resistance and can be used at temperatures up to 200°C. It is a high-temperature cable that complies with UL3645 and has excellent high-temperature resistance. It is mainly used for wiring inside enclosed electrical appliances, providing reliable insulation and electrical performance to ensure the normal operation and safety of electrical equipment. In addition, the cable has anti-aging and chemical corrosion resistance, which makes it suitable for a variety of harsh working environments.

GET A QUOTE

high temperature coaxial cable Characterization;

- Good elasticity, softness

- Good adsorption ability

- Good heat resistance

- Good cold resistance

- Good weather resistance

- Good chemical stability

- Good heat dissipation properties

- Good flame retardancy

high temperature coaxial cable Electrical Performance:

- Good electrical insulation properties

- With high resistivity

high temperature coaxial cable Processing performance:

- Using cold extrusion process

- Or the use of high-temperature vulcanization process

- Good harness processing performance

- Good compatibility in the process of harness processing

- According to UL standard design

high temperature coaxial cable Eco-friendly:

- Comply with ROHS/REACH

- Odorless and non-toxic

high temperature coaxial cable Appliance:

- Internal wiring for enclosed appliances

high temperature coaxial cable Reference standard:

- UL758-2010、UL1581-2009

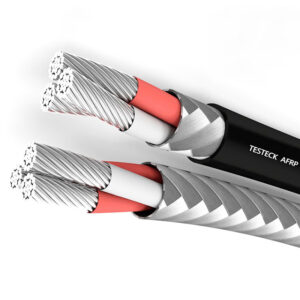

high temperature coaxial cable Structure:

- Conductor structure: tinned/bare conductor

- Insulation Material: Silicone Rubber Insulation

- Braid: Glass fiber braid (or silicone sheath)

Parameter:

| Silicone rubber insulated wire for internal use with conductor temperature not exceeding 200℃. Rated temperature:200℃ Rated voltage:1000V |

||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Specification AWG | Conductor Structure(mm)±0.005mm | Conductor Resistance

20℃(Ω/Km) |

Conductor Diameter(mm) | Insulation Thickness (mm) |

Finished Outer Diameter(mm) | ||

| Average value | Minimum value | Average value | Tolerance | |||||

| 3645 | 2 | 7/95/0.254 | 0.555 | 8.58 | 1.52 | 1.37 | 11.62 | ±0.20 |

| 4 | 7/60/0.254 | 0.882 | 6.82 | 1.52 | 1.37 | 9.86 | ±0.20 | |

| 6 | 7/38/0.254 | 1.403 | 5.43 | 1.52 | 1.37 | 8.85 | ±0.15 | |

| 8 | 168/0.254 | 2.230 | 3.80 | 1.52 | 1.37 | 7.25 | ±0.15 | |

| 10 | 105/0.254 | 3.55 | 3.00 | 1.15 | 1.02 | 5.70 | ±0.15 | |

| 12 | 65/0.254 | 5.64 | 2.36 | 1.15 | 1.02 | 5.06 | ±0.15 | |

| 14 | 41/0.254 | 8.96 | 1.88 | 1.15 | 1.02 | 4.60 | ±0.15 | |

| 16 | 26/0.254 | 14.60 | 1.50 | 1.15 | 1.02 | 4.20 | ±0.15 | |

| 18 | 16/0.254 | 23.20 | 1.19 | 1.15 | 1.02 | 3.90 | ±0.15 | |

| 20 | 21/0.18 | 36.70 | 0.92 | 1.15 | 1.02 | 3.62 | ±0.15 | |

| 22 | 7/0.254 | 59.40 | 0.76 | 1.15 | 1.02 | 3.46 | ±0.15 | |

| 24 | 7/0.20 | 94.20 | 0.61 | 1.15 | 1.02 | 3.30 | ±0.15 | |

| 26 | 7/0.16 | 150.00 | 0.48 | 1.15 | 1.02 | 3.20 | ±0.15 | |

| 28 | 7/0.127 | 239.00 | 0.38 | 1.15 | 1.02 | 3.10 | ±0.15 | |

| 30 | 7/0.10 | 381.00 | 0.30 | 1.15 | 1.02 | 3.00 | ±0.15 | |

| Braid thickness:0.20mm | ||||||||

This post is also available in:

English