UL3513 0.50-120.0MM2 heat resistant single core cable

This product is a 200℃ silicone high temperature cable certified by UL3513, which is often used for wiring inside equipment. UL3513 certification ensures that this cable meets relevant safety standards and high temperature resistance requirements, and is suitable for electrical connections inside equipment. This silicone high temperature cable can operate stably for a long time in a high temperature environment, ensuring that the wiring inside the equipment is safe and reliable. Therefore, UL3513 silicone high temperature cable is an ideal choice for wiring inside equipment.

GET A QUOTE

heat resistant single core cable Characterization;

-

- Excellent mechanical properties.

Tensile strength>3.45MPa, elongation at break>100%After aging.

Condition:232s 1.0℃/168H

Residual rate of tensile strength>60% Residual rate of elongation at break>25 - Flame retardant: FT2, horizontal burning, burning 1 time, each time 30S, during the test period on the specimen can not send out any particles or droplets that ignite the cotton layer.

Low-temperature bending: -10 ℃ 兾 2 ℃ / 4H, the specimen surface is qualified without cracks

- Excellent mechanical properties.

heat resistant single core cable Electrical Performance:

- Rated temperature: 200 ℃ Rated voltage: 600V

- Spark test: no breakdown when passing through the test electrode. Spark test voltage is 6KV

- Dielectric withstand voltage: 2.0KV, 60 seconds without breakdown

heat resistant single core cable Processing performance:

- Using cold extrusion process

- Or the use of high-temperature vulcanization process

- Good harness processing performance

- Good compatibility in the process of harness processing

- According to UL standard design

heat resistant single core cable Eco-friendly:

- Comply with ROHS/REACH

- Odorless and non-toxic

heat resistant single core cable Appliance:

- Equipment internal wiring

heat resistant single core cable Reference standard:

- UL758-2010、UL1581-2009

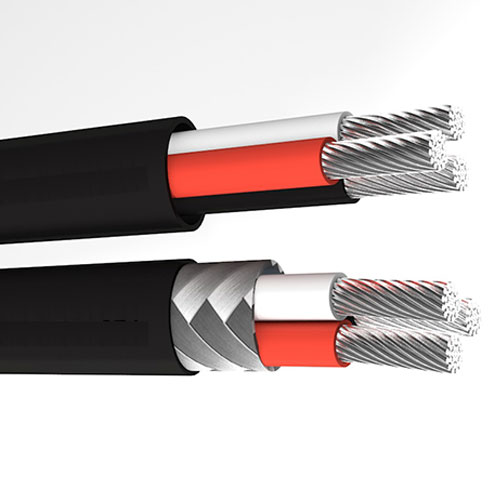

heat resistant single core cable Structure:

- Conductor structure: tin-plated / bare conductor

- Body insulation material: 22 types of silicone rubber insulation

- Braiding: glass fiber braiding

Parameter:

| Silicone rubber insulated wires with conductor temperature not exceeding 200℃ for internal wiring of equipment. Rated temperature:200℃ Rated voltage:600V |

||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Specification mm |

Conductor Structure(mm)±0.005mm | Conductor Resistance

20℃/Km) |

Conductor Diameter(mm) | Insulation Thickness (mm) |

Finished Outer Diameter(mm) |

||

| Average value | Minimum value | Average value | Tolerance | |||||

| 3513 | 0.50 | 16/0.2 | 40.1 | 0.92 | 0.76 | 0.69 | 2.74 | ±0.15 |

| 1.00 | 40/0.18 | 20.00 | 1.30 | 0.76 | 0.69 | 3.13 | ±0.15 | |

| 1.25 | 50/0.18 | 15.10 | 1.50 | 0.76 | 0.69 | 3.30 | ±0.15 | |

| 1.50 | 30/0.25 | 13.70 | 1.60 | 0.76 | 0.69 | 3.43 | ±0.15 | |

| 2.00 | 41/0.254 | 9.50 | 1.90 | 0.76 | 0.69 | 3.70 | ±0.15 | |

| 2.50 | 49/0.25 | 8.21 | 2.00 | 0.76 | 0.69 | 3.97 | ±0.15 | |

| 4.00 | 56/0.30 | 5.09 | 2.60 | 0.76 | 0.69 | 4.41 | ±0.15 | |

| 5.00 | 105/0.254 | 4.02 | 2.96 | 1.15 | 1.01 | 5.57 | ±0.15 | |

| 6.00 | 84/0.30 | 3.39 | 3.20 | 1.15 | 1.01 | 5.78 | ±0.15 | |

| 10.0 | 80/0.40 | 1.88 | 4.13 | 1.52 | 1.37 | 7.47 | ±0.15 | |

| 16.0 | 7/18/0.40 | 1.72 | 5.90 | 1.52 | 1.37 | 9.22 | ±0.15 | |

| 25.0 | 7/28/0.40 | 1.081 | 7.40 | 1.52 | 1.37 | 10.67 | ±0.20 | |

| 35.0 | 1/44/0.4+6/39/0.4 | 0.538 | 8.83 | 1.52 | 1.37 | 12.17 | ±0.20 | |

| 50.0 | 19/21/0.4 | 0.375 | 10.59 | 2.03 | 1.83 | 14.95 | ±0.30 | |

| 70.0 | 19/30/0.4 | 0.277 | 12.65 | 2.03 | 1.83 | 17.01 | ±0.30 | |

| 95.0 | 19/25/0.50 | 0.200 | 14.44 | 2.03 | 1.93 | 18.80 | ±0.30 | |

| 120.0 | 19/32/0.50 | 0.156 | 16.33 | 2.41 | 2.16 | 21.45 | ±0.40 | |

| Braid thickness:0.15mm | ||||||||

This post is also available in:

English