UL3278 4/0-8AWG high temperature wire 18 awg cables

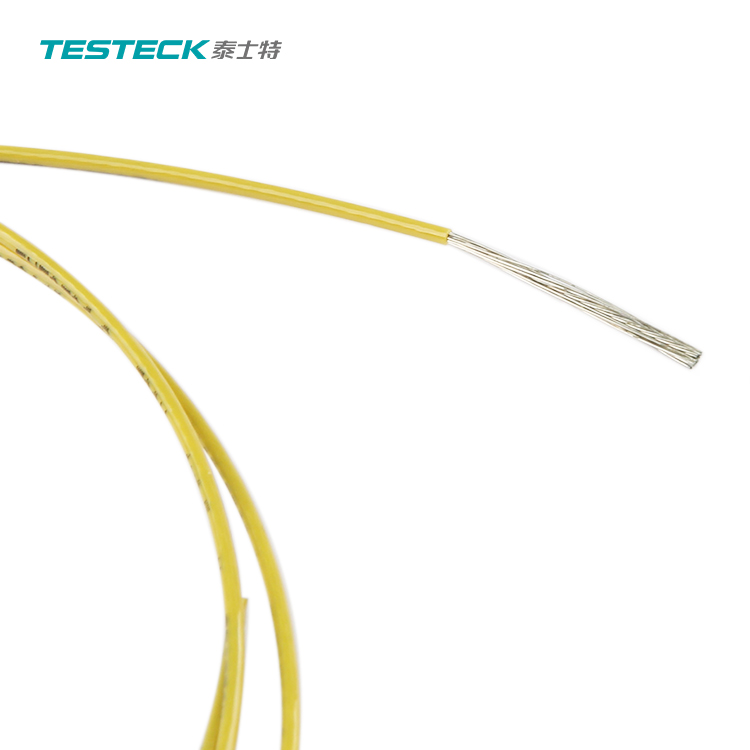

This UL3278 certified 150°C cable is designed for internal wiring of electrical appliances and is particularly suitable for applications such as heating equipment and lighting fixtures. With its excellent high temperature resistance, it can maintain stable and safe operation in harsh environments up to 150°C for long periods of time. Complying with the stringent requirements of UL3278, this cable provides reliable electrical connections and long-lasting durability, making it an ideal solution for high-temperature electrical equipment.

GET A QUOTE

UL3278 4/0-8AWG high temperature wire 18 awg Characterization;

- Good elasticity, softness

- Good adsorption ability

- Good heat resistance

- Good cold resistance

- Good weather resistance

- Good chemical stability

- Good heat dissipation properties

- Good flame retardancy

UL3278 4/0-8AWG high temperature wire 18 awg 18 awg Electrical Performance:

- Good electrical insulation properties

- With high resistivity

UL3278 4/0-8AWG high temperature wire 18 awg Processing performance:

- Using cold extrusion process

- Or the use of high-temperature vulcanization process

- Good harness processing performance

- Good compatibility in the process of harness processing

- According to UL standard design

UL3278 4/0-8AWG high temperature wire 18 awg Eco-friendly:

- Comply with ROHS/REACH

- Odorless and non-toxic

UL3278 4/0-8AWG high temperature wire 18 awg Appliance:

- Internal wiring of electrical appliances (e.g., heating and lighting equipment)

UL3278 4/0-8AWG high temperature wire 18 awg Reference standard:

- UL758-2010、UL1581-2009

UL3278 4/0-8AWG high temperature wire 18 awg Structure:

- Conductor structure: tinned/bare conductor

- Insulation Material: Silicone Rubber Insulation

- Braiding:Glass Fiber Braid

Parameter:

| Internally wired, silicone rubber insulated wire with conductor temperature not exceeding 150°C Rated temperature:150℃ Rated voltage:600V |

||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Specification AWG |

Conductor Structure(mm)±0.005mm | Conductor Resistance

20℃Ω/Km) |

Conductor Diameter(mm) | Insulation Thickness (mm) |

Finished Outer Diameter(mm) | ||

| Average value | Minimum value | Average value | Tolerance | |||||

| 3278 | 4/0 | 19/44/0.404 | 0.172 | 15.48 | 2.03 | 1.83 | 19.95 | ±0.30 |

| 3/0 | 19/87/0.254 | 0.219 | 13.68 | 2.03 | 1.83 | 18.15 | ±0.30 | |

| 2/0 | 19/70/0.254 | 0.277 | 12.26 | 2.03 | 1.83 | 16.72 | +0.30 | |

| 1/0 | 19/55/0.254 | 0.349 | 10.88 | 2.03 | 1.83 | 15.35 | ±0.30 | |

| 1 | 19/44/0.254 | 0.440 | 9.72 | 2.03 | 1.83 | 14.20 | ±0.20 | |

| 2 | 7/95/0.254 | 0.555 | 8.58 | 1.52 | 1.37 | 12.02 | ±0.20 | |

| 4 | 7/60/0.254 | 0.882 | 6.82 | 1.52 | 1.37 | 10.26 | ±0.20 | |

| 6 | 7/38/0.254 | 1.403 | 5.41 | 1.52 | 1.37 | 8.85 | ±0.20 | |

| 8 | 168/0.254 | 2.230 | 3.80 | 1.52 | 1.37 | 7.25 | ±0.20 | |

| Braid thickness:0.20mm | ||||||||

This post is also available in:

English