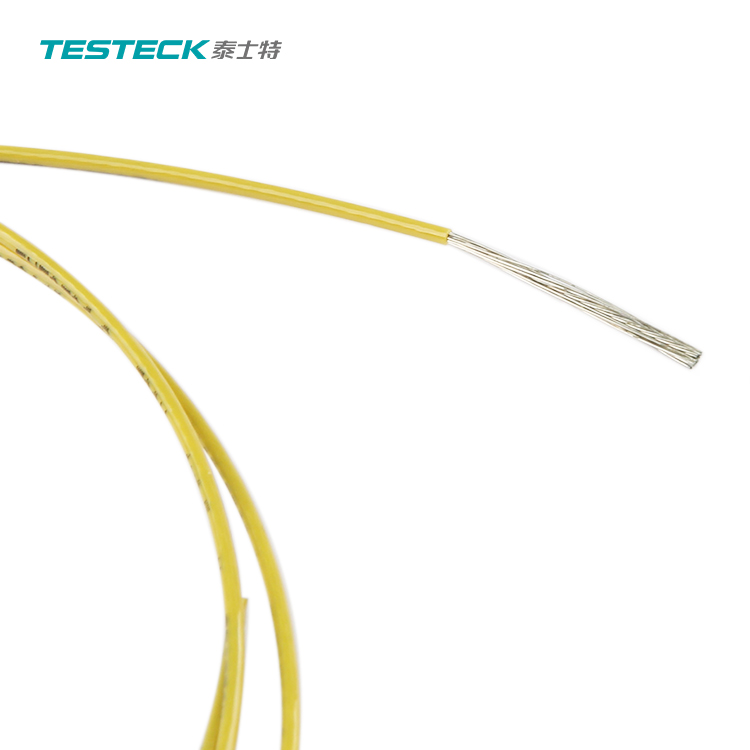

UL3138 10-18AWG high temperature flexible cable silicone wires

Introducing the advanced UL3138 certified 150°C cable, designed to meet the internal wiring needs of appliances in high temperature conditions. UL3138 certified, this cable is guaranteed to maintain excellent electrical performance and structural stability in environments as high as 150°C. The product utilizes top-quality materials and precision machining to ensure durability and reliability under high-temperature operating conditions, providing a high-quality, safe internal power connection solution for a variety of electrical products.

GET A QUOTE

UL3138 10-18AWG high temperature flexible cable Characterization;

- Good elasticity, softness

- Good adsorption ability

- Good heat resistance

- Good cold resistance

- Good weather resistance

- Good chemical stability

- Good heat dissipation properties

- Good flame retardancy

UL3138 10-18AWG high temperature flexible cable Electrical Performance:

- Good electrical insulation properties

- With high resistivity

UL3138 10-18AWG high temperature flexible cable Processing performance:

- Using cold extrusion process

- Or the use of high-temperature vulcanization process

- Good harness processing performance

- Good compatibility in the process of harness processing

- According to UL standard design

UL3138 10-18AWG high temperature flexible cable Eco-friendly:

- Comply with ROHS/REACH

- Odorless and non-toxic

UL3138 10-18AWG high temperature flexible cable Appliance:

- Internal wiring for electrical appliances

UL3138 10-18AWG high temperature flexible cable Reference standard:

- UL758-2010、UL1581-2009

UL3138 10-18AWG high temperature flexible cable Structure:

- Conductor structure: tin/silver/nickel plated copper conductor

- Insulation Material: Silicone Rubber Insulation

Parameter:

| Silicone rubber insulated wires for internal wiring of electrical appliances with conductor temperature not exceeding 150℃. Rated temperature:150℃ Rated voltage:600V |

||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Specification AWG |

Conductor structure(mm)±0.005mm | Conductor Resistance

20℃2/Km) |

Conductor Diameter(mm) | Insulation Thickness (mm) |

Finish Outer Diameter(mm) | ||

| Average value | Minimum value | Average value | Tolerance | |||||

| 3138 | 10 | 105/0.254 | 3.54 | 3.00 | 1.15 | 1.02 | 5.30 | ±0.15 |

| 12 | 65/0.254 | 5.64 | 2.36 | 1.15 | 1.02 | 4.65 | ±0.15 | |

| 14 | 41/0.254 | 8.96 | 1.90 | 1.15 | 1.02 | 4.20 | ±0.15 | |

| 16 | 7/0.49 | 14.60 | 1.50 | 1.15 | 1.02 | 3.80 | ±0.15 | |

| 18 | 7/0.39 | 23.20 | 1.19 | 1.15 | 1.02 | 3.50 | ±0.15 | |

This post is also available in:

English