Silicone DC High Voltage Wire & Cable

Silicone DC High Voltage Wire & Cable is excellent high temperature and low temperature resistance, excellent electrical insulation performance, excellent chemical stability, high voltage resistance, aging resistance, and long service life. It is also flexible and easy to install.

GET A QUOTE

Application:

“Widely used in gas ignition, automotive ignition, high-voltage test benches, televisions, microwave ovens, neon lights, high-voltage internal parts of instruments and meters, installation connections for electronic appliances, and other high-voltage applications.”

Characteristic:

- Rated voltage: 5kV, 10kV, 15kV, 20kV, 25kV, 30kV, 50kV, 100kV.

- Operating temperature: -60~+200°C.

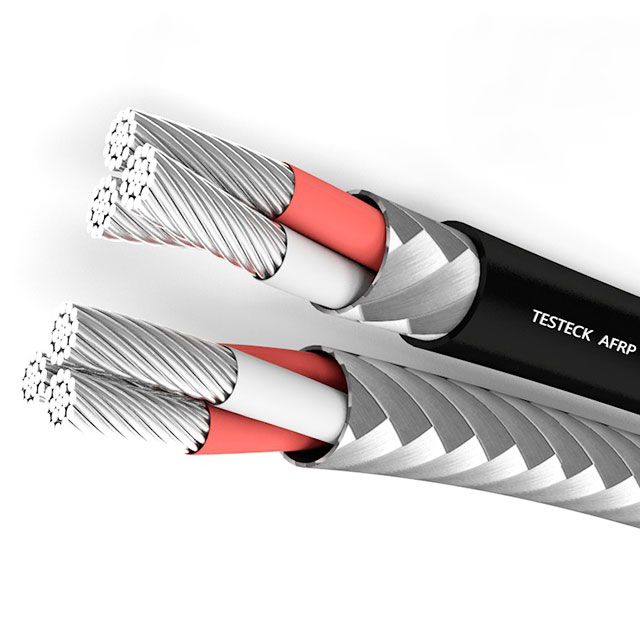

- Conductor: Tinned copper stranded wire.

- Insulation: Silicone rubber.

- Color: Customizable.

Industry Standard

- Q31/0114000209C026-2017

Selection parameter

| Voltage level | Conductor nominal cross section | Conductor structure | Insulation thickness | Average outer diameter | Maximum DC resistance of conductor at 20℃ |

| KV | mm2 | Number of roots/single wire diameter | mm | mm | Ω/km |

| 5 | 0.2 | 7/0.20 | 1 | 2.6 | 95 |

| 0.35 | 19/0.16 | 1 | 2.8 | 53.1 | |

| 0.5 | 16/0.20 | 1 | 3 | 10.1 | |

| 0.75 | 24/0.20 | 1.2 | 3.6 | 26.7 | |

| 1 | 32/0.20 | 1.3 | 4 | 20 | |

| 1.5 | 30/0.25 | 1.5 | 4.6 | 13.7 | |

| 2.5 | 49/0.25 | 1.6 | 5.4 | 8.21 | |

| 10 | 0.2 | 7/0.20 | 1.3 | 3.2 | 95 |

| 0.35 | 19/0.16 | 1.3 | 3.4 | 53.1 | |

| 0.5 | 16/0.20 | 1.3 | 3.6 | 10.1 | |

| 0.75 | 24/0.20 | 1.5 | 4.2 | 26.7 | |

| 1 | 32/0.20 | 1.5 | 4.4 | 20 | |

| 1.5 | 30/0.25 | 1.8 | 5.2 | 13.7 | |

| 2.5 | 49/0.25 | 1.8 | 5.8 | 8.21 | |

| 4 | 56/0.30 | 2 | 6.8 | 5.09 | |

| 6 | 84/0.30 | 2 | 7.6 | 3.39 | |

| 15 | 0.2 | 7/0.20 | 1.7 | 4 | 95 |

| 0.35 | 19/0.16 | 1.7 | 4.2 | 53.1 | |

| 0.5 | 16/0.20 | 1.7 | 4.4 | 40.1 | |

| 0.75 | 24/0.20 | 2 | 5.2 | 26.7 | |

| 1 | 32/0.20 | 2 | 5.3 | 20 | |

| 1.5 | 30/0.25 | 2.2 | 6 | 13.7 | |

| 2.5 | 49/0.25 | 2.2 | 6.6 | 8.21 | |

| 4 | 56/0.30 | 2.4 | 7.6 | 5.09 | |

| 6 | 84/0.30 | 2.4 | 8.4 | 3.39 | |

| 20 | 0.2 | 7/0.20 | 1.8 | 4.2 | 95 |

| 0.35 | 19/0.16 | 1.8 | 4.4 | 53.1 | |

| 0.5 | 16/0.20 | 1.8 | 4.6 | 40.1 | |

| 0.75 | 24/0.20 | 2.2 | 5.6 | 26.7 | |

| 1 | 32/0.20 | 2.2 | 5.8 | 20 | |

| 1.5 | 30/0.25 | 2.4 | 6.4 | 13.7 | |

| 2.5 | 49/0.25 | 2.4 | 7 | 8.21 | |

| 4 | 56/0.30 | 2.6 | 8 | 5.09 | |

| 6 | 84/0.30 | 2.6 | 8.8 | 3.39 | |

| 25 | 0.2 | 7/0.20 | 2.5 | 5.6 | 95 |

| 0.35 | 19/0.16 | 2.5 | 5.8 | 53.1 | |

| 0.5 | 16/0.20 | 2.5 | 6 | 40.1 | |

| 0.75 | 24/0.20 | 2.7 | 6.6 | 26.7 | |

| 1 | 32/0.20 | 2.7 | 6.8 | 20 | |

| 1.5 | 30/0.25 | 2.9 | 7.5 | 13.7 | |

| 2.5 | 49/0.25 | 2.9 | 8 | 8.21 | |

| 4 | 56/0.30 | 3.1 | 9 | 5.09 | |

| 6 | 84/0.30 | 3.1 | 9.8 | 3.39 | |

| 30 | 0.2 | 7/0.20 | 3 | 6.6 | 95 |

| 0.35 | 19/0.16 | 3 | 6.8 | 53.1 | |

| 0.5 | 16/0.20 | 3 | 7 | 40.1 | |

| 0.75 | 24/0.20 | 3.4 | 8 | 26.7 | |

| 1 | 32/0.20 | 3.4 | 8.2 | 20 | |

| 1.5 | 30/0.25 | 3.6 | 9 | 13.7 | |

| 2.5 | 49/0.25 | 3.6 | 9.4 | 8.21 | |

| 4 | 56/0.30 | 3.8 | 10.5 | 5.09 | |

| 6 | 84/0.30 | 3.8 | 11.2 | 3.39 | |

| 50 | 0.2 | 7/0.20 | 7 | 14.6 | 95 |

| 0.35 | 19/0.16 | 7 | 14.8 | 53.1 | |

| 0.5 | 16/0.20 | 7 | 15 | 40.1 | |

| 0.75 | 24/0.20 | 7.2 | 15.6 | 26.7 | |

| 1 | 32/0.20 | 7.2 | 15.8 | 20 | |

| 1.5 | 30/0.25 | 7.5 | 16.6 | 13.7 | |

| 2.5 | 49/0.25 | 7.5 | 17.2 | 8.21 | |

| 4 | 56/0.30 | 8 | 19 | 5.09 | |

| 6 | 84/0.30 | 8 | 20 | 3.39 | |

| 100 | 1 | 32/0.30 | 12 | 25 | 20 |

| 1.5 | 30/0.25 | 13 | 27.8 | 13.7 | |

| 2.5 | 49/0.25 | 13 | 28.5 | 8.21 | |

| TIPS:According to the technical agreement between the two parties, products of other specifications can be produced. | |||||

Also available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese

WHY CHOOSE TST

19 quality tests before cable shipment

R&D personnel account for 42% of the company’s headcount

Support all kinds of customization, free sampling

10,000 ㎡ factory, annual production capacity of 2,000,000 meters