1. Physical properties

a. Excellent mechanical properties

b. Excellent thermal stability

C. Good low temperature flexibility

d. Good flame retardancy

e. High chemical resistance

g. Good chemical stability

2. Electrical properties

a. Good electrical insulation properties

b. Good dielectric properties

3. Processing performance

a. Use hot extrusion processing

b. Can be twisted and multi-core twisted wires

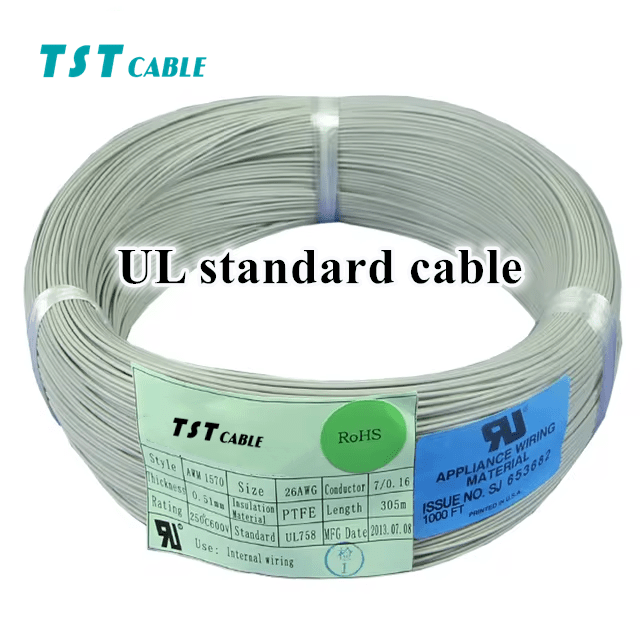

C. Designed according to UL standards

4. Environmental protection

a. Low smoke and halogen-free

b. Compliant with ROHS/REACH

4. Environmental protection

a. Compliant with ROHS/REACH

Application:

Wires for connecting electronic equipment

Reference standards:

UL758-2010, UL1581-2009

| model | SpecificationAWG | Conductor structure(pieces/mm) | Conductor resistance20℃(Q/Km) | Conductor diameter (mm) | Insulation thickness(mm) | Finished outer diameter(mm) | ||

|---|---|---|---|---|---|---|---|---|

| average value | Minimum | average value | tolerance | |||||

| ul3597 | 16 | 26/0.254 | 14.60 | 1.50 | 0.40 | 0.33 | 2.30 | ±0.10 |

| 18 | 16/0.254 | 23.20 | 1.17 | 0.40 | 0.33 | 1.97 | ±0.10 | |

| 20 | 21/0.18 | 36.70 | 0.95 | 0.40 | 0.33 | 1.75 | ±0.10 | |

| 22 | 17/0.16 | 59.40 | 0.76 | 0.40 | 0.33 | 1.56 | ±0.10 | |

| 24 | 11/0.16 | 94.20 | 0.61 | 0.40 | 0.33 | 1.41 | ±0.10 | |

| 26 | 7/0.16 | 150.00 | 0.48 | 0.40 | 0.33 | 1.28 | ±0.10 | |

| 28 | 7/0.127 | 239.00 | 0.38 | 0.40 | 0.33 | 1.18 | ±0.10 | |

| 30 | 7/0.10 | 381.0 | 0.30 | 0.40 | 0.33 | 1.10 | ±0.10 | |

Additional note: In addition to the cables with the above specifications, other specifications of UL cables can also be customized. For details, please contact us by email.

Also available in:

English