Railway Cable aircraft cable Vehicle jumper cable EN50382

Railway Cable aircraft cable Vehicle jumper cable which applied in Railway control system (Railway Power Cable, Control Cable, Railway Data Transmission Cable, Railway Sensor Cable, Ticket machine), Railway communication system (Railway Coaxial Cable, RF Cable, Railway Ethernet Cable), Railway multimedia system (Speaker Cable, Microphone Cable, Video Cable for monitor.)

GET A QUOTE

Product introduction

TST Cables supplies Railway system cables met EN 45545-2, IEC 60332-1-2 / IEC 60332-3, EN60305, EN 61034-2, EN 60864-2, EN 60754 -1 / EN 60754-2 which applied in Railway control system (Railway Power Cable, Control Cable, Railway Data Transmission Cable, Railway Sensor Cable, Ticket machine), Railway communication system (Railway Coaxial Cable, RF Cable, Railway Ethernet Cable), Railway multimedia system (Speaker Cable, Microphone Cable, Video Cable for monitor.). We provide wide range OEM service of railway rolling stock items from wire to multicores cable spec for customer’s application.

Product parameters

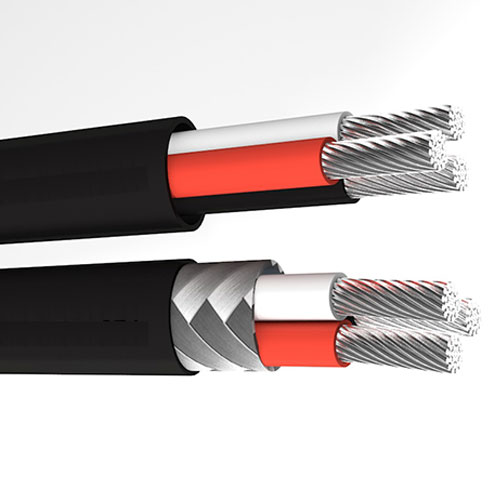

- Model: TST-382 Jumper Cable

- Conductor: Tinned copper conductor Category 6 construction

- Insulation: silicone rubber

- Braided reinforcement: polyester or aramid

- Rated voltage: 3.6/6.0kV

- Dielectric strength:>8MPa

- Elongation at break:>200%

- Cable bending radius: 6D (D cable outer diameter)

- Operating temperature: -50°C to +150°C

- Service voltage:300V/500V

- Test voltage :2,500V

- Minimum bend radius in fixed installation 5 x outer diameter

- Minimum bend radius in flexible installation 7.5 x outer diameter

Optimized cable structure:

power jumper, control jumper, data jumper, comprehensive jumper

Satisfied applications

① Fire resistance ② Low smoke emission

③ Low toxicity ④ Sun aging resistance ⑤ Oil resistance

⑥ Weather resistance ⑦ Mechanical resistance

Reliability

TST cables many years of experience in jumper cables: The verification of bending durability and torsional durability is an effective guarantee for the safety of vehicle operation. The experiment is more than 500,000 times according to JRLS J 1000-5.4.2 and JRIS J 100-5.4.3, experiments were conducted more than 500000 times.

Fire resistant properties

- EN45545-2 HL1 — HL3 Test

- single vertical EN60332-1-2

- Smoke density EN61034-2

- toxicity EN50305-9-2

All qualification certifications for the railway industry

- CRCC certified enterprise

- TS22163 (International Railway Quality Management System)

- ISO9001 (quality system)

- CE product certification

- ECER118 fire protection

Also available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese