200℃ Lightweight high-temperature resistant anti-interference railway signal control cable & wire

Lightweight high-temperature resistant anti-interference railway signal control cable & wire specifically developed for railway vehicles. This cable is halogen-free, meaning it does not contain halogen compounds. In the event of a fire, it does not release any corrosive gases, making it safer for passengers and equipment. It is flame-retardant, meaning it resists the spread of fire, and emits low levels of smoke, reducing visibility obstruction and potential respiratory hazards. The cable also has a low toxicity index, minimizing the harmful effects of any potential emissions.

GET A QUOTE

Application:

Lightweight high-temperature resistant anti-interference railway signal control cable & wire is particularly suitable for wiring control panels, electrical control boxes, carriage wiring, power supply to various systems in terminal boxes, and ground connections for mobile devices within railway vehicles. It meets the requirements of European railway fire protection standards, ensuring compliance with safety regulations and standards in railway applications.

Characteristic:

- Temperature resistance: -50°C to 200°C

- Voltage rating: 600V

- Insulation strength: >10MPa

- Elongation at break: >125%

- Fire resistance rating: Meets HL3 of EN45545-2 R15/R16

Industry Standard:

- Comply with TB/T1484.1-2017 and TJ/CL254-2013 locomotive and passenger car vehicle cable requirements through EN45545, HL1, HL2 and HL3 requirements inside and outside the vehicle.

- Comply with the requirements of BS6853:1999 for la, lb, and class locomotives regarding internal and external cables. Passed

- BS6853:1999 and DIN5510-2:2009 fire, smoke, and toxicity tests. Comply with the requirements of flammability class S1~S5 in DIN5510-2:2009.

- Passed China Railway Products CRCC certification.

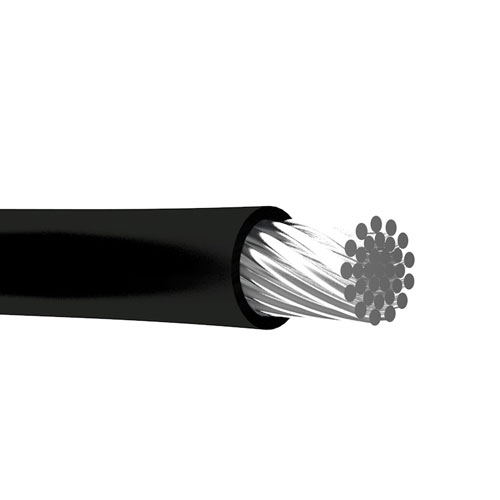

Structure:

- Conductor: Flexible tinned annealed copper wire with Class 5 structure.

- Insulation: Standard low-smoke, halogen-free elastomeric compound.

- Jacket: Standard low-smoke, halogen-free elastomeric compound.

- Cable bending radius: 6 times the cable outer diameter (6D).

Selection parameter

| Nominal cross section | Number of wires * Conductor diameter | Conductor stranding diameter | Insulation average thickness | Outer diameter (D) | 20℃ conductor resistance max | Reference weight | Fire load | ||

|---|---|---|---|---|---|---|---|---|---|

| min | max | min | min | max | |||||

| mm | n xmm | mm | mm | mm | mm | mm | Ω/km | Kg/k m | KJ/m |

| 0.5 | 19×0.18 | 0.8 | 0.95 | 0.18 | 1.15 | 1.45 | 40.1 | 5.9 | 22 |

| 0.75 | 37×0.16a | 1 | 1.15 | 0.18 | 1.35 | 1.65 | 26.7 | 8.1 | 27 |

| 1 | 37×0.18a | 1.1 | 1.3 | 0.18 | 1.45 | 1.8 | 20 | 10.1 | 33 |

| 1.5 | 37×0.23a | 1.45 | 1.65 | 0.22 | 1.95 | 2.3 | 13.7 | 16.5 | 58 |

| 2.5 | 37×0.30 | 1.85 | 2.15 | 0.28 | 2.5 | 2.85 | 8.21 | 27.5 | 72 |

Also available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese