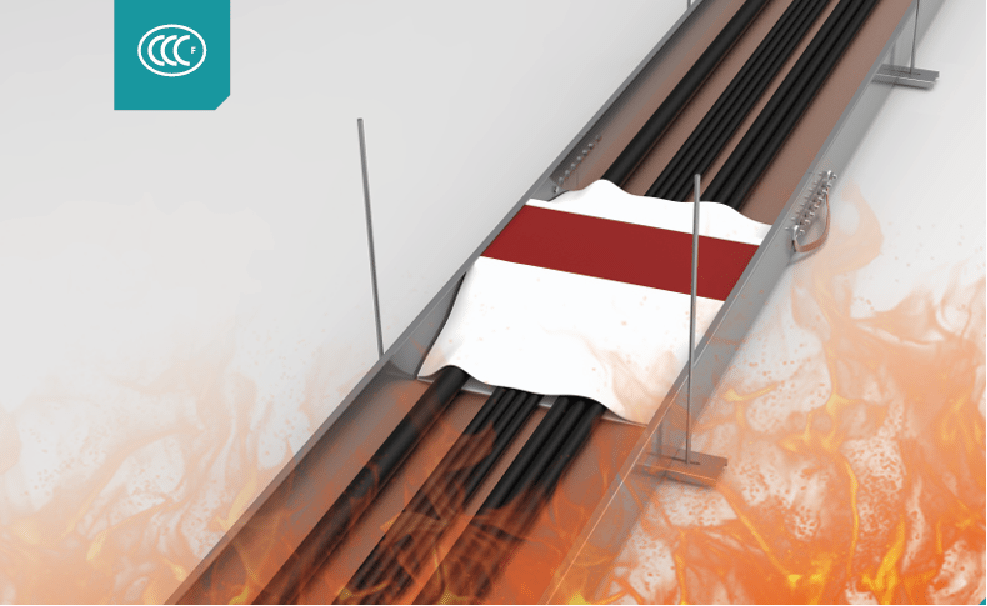

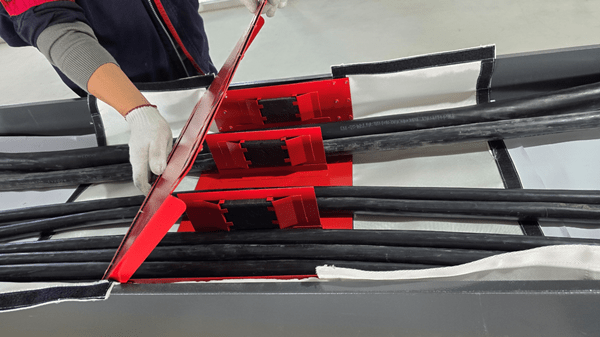

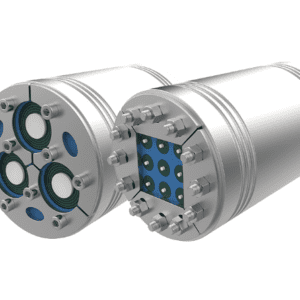

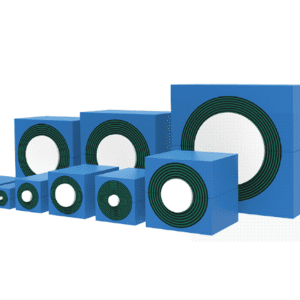

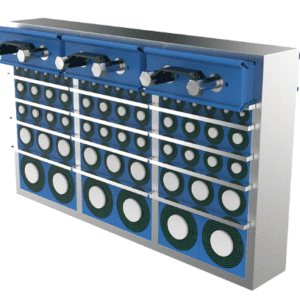

The light fire-blocking section is a fire-blocking isolation product made of a new type of intumescent fireproof material of TST CABLES. It consists of a fuel expansion block, a fireproof cloth, a combined metal frame sprayed with fireproof paint and a fireproofing cloth.

Technical background

In the fireproof blocking process, the common fire-blocking section is usually built with traditional materials, mainly composed of fireproof boards, fireproof bags, and fireproof mud. There are disadvantages such as long installation and construction time, heavy weight, poor heat dissipation, and short life. In particular, the accumulation of heat from the cable with large heat generation will cause carbonization of the cable insulation layer and outer sheath, which undoubtedly reduces the service life of the cable and increases the fire hazard.

Application scenario

According to the requirements of GB50217 and GB50872, the following parts of the overhead bridge should be equipped with fire-blocking sections:

The branch of the main channel of the overhead bridge;

The long-distance overhead bridge is 100m apart;

The entrance of the overhead bridge to the control room or distribution device, and the factory wall.

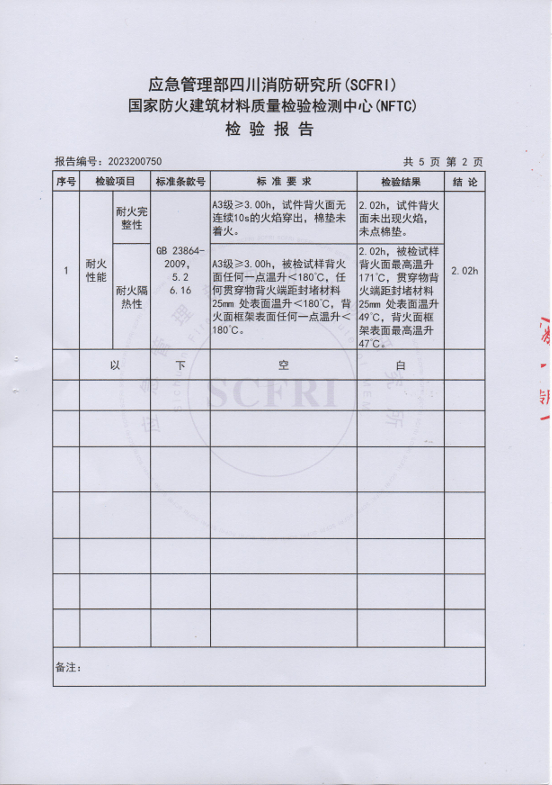

Standard requirements for fire-blocking sections

The fire-blocking section should be constructed with fire-proof sealing materials suitable for cable laying conditions, and should be stable under the conditions of possible water immersion or rodent damage;

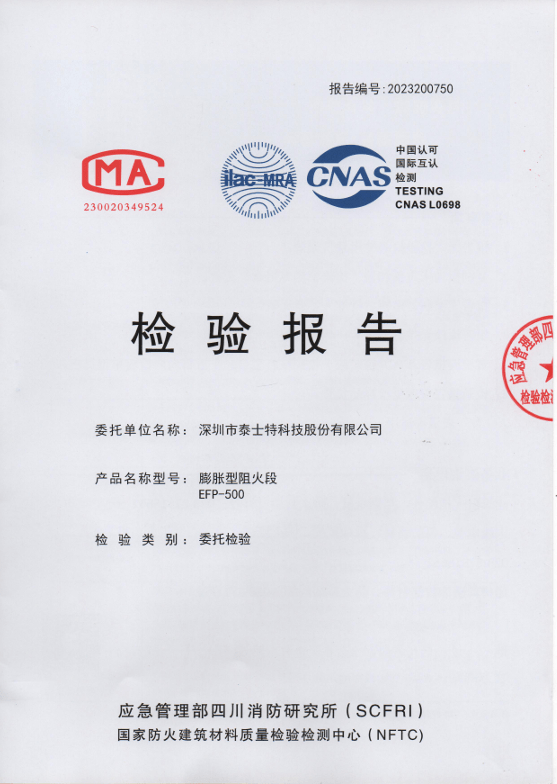

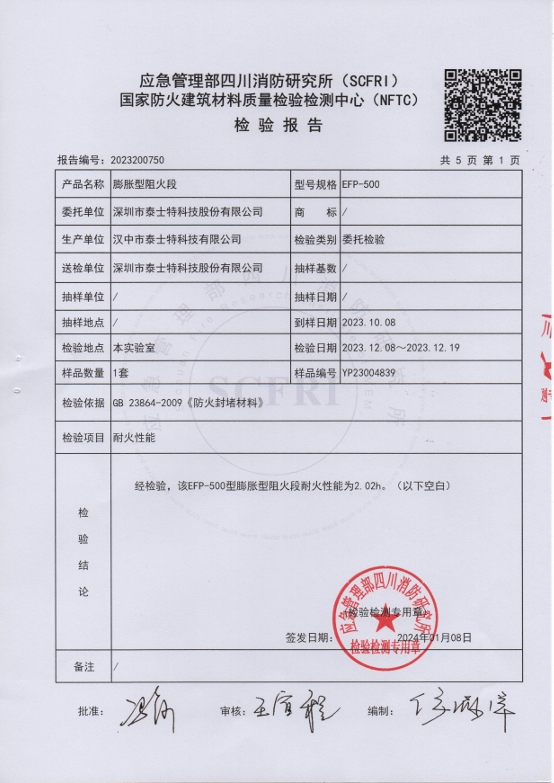

The fire resistance limit should not be less than 1h, and the combustion performance, physical and chemical properties and fire resistance performance should comply with GB23864, and the test conditions should be consistent with the actual conditions.

Technical indicators and characteristics of light fire-blocking section

Technical indicators

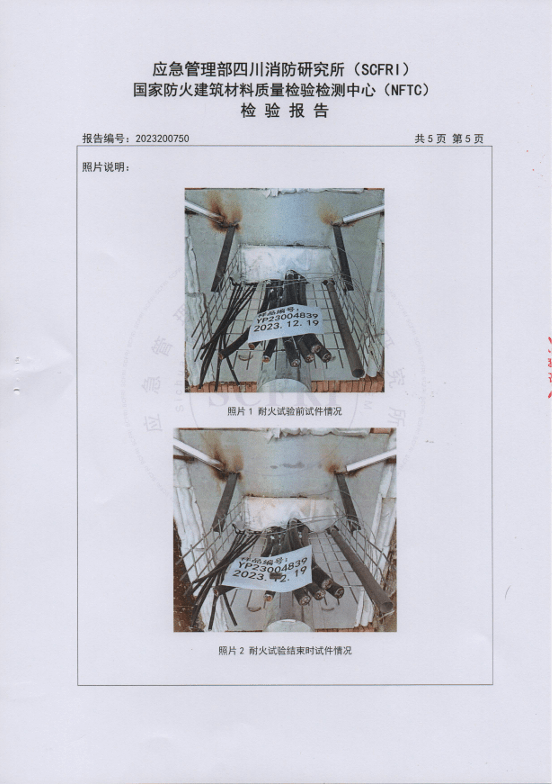

Fireproof grade: GB23864 (2h thermal insulation performance, 2h fire resistance integrity);

Lifespan: 15 years;

Features

Light weight, single set weight is not more than 5kg;

Easy to install, generally it can be installed in 10min~15min;

It is very friendly to transformation or upgrade, and it is very convenient to add or replace cables later;

It can also be installed after the cable is laid;

The materials used have good corrosion resistance and are suitable for a variety of environments, including harsh conditions such as humidity and salt spray

The structure is stable and does not require maintenance;

It is conducive to heat dissipation: its state is almost the same as the laying state in the bridge, which greatly reduces the risk of cable aging caused by heat accumulation in the traditional fire-blocking section;

More beautiful: the design is more modern and beautiful, which can enhance the appearance of the entire building or machine room; due to its low installation and maintenance costs and long service life, the comprehensive cost is lower than that of traditional bridges.

Also available in:

Arabic

English

Indonesian

Japanese

Russian

Vietnamese

Portuguese (Brazil)