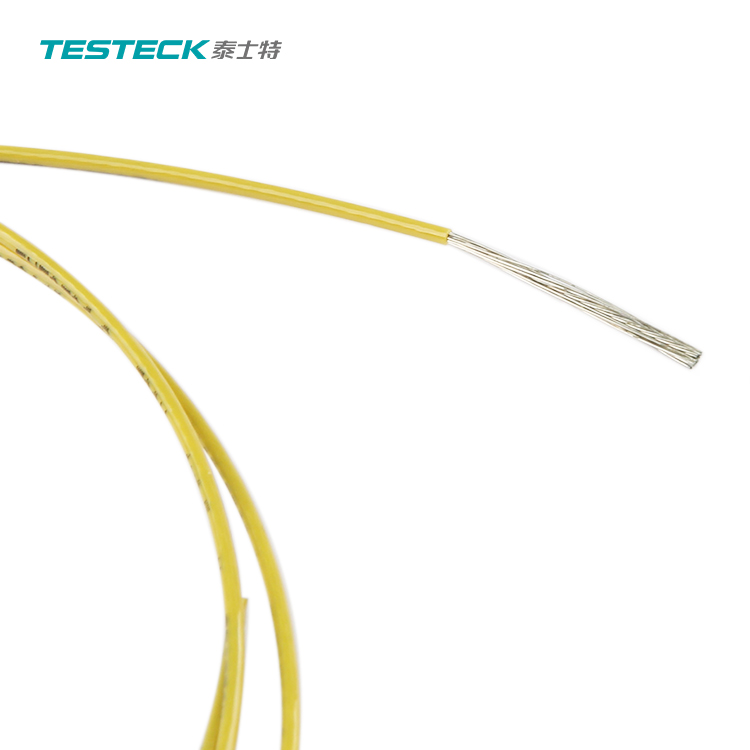

AFF250 Teflon high temperature cable

It has excellent corrosion resistance, oil resistance, strong acid resistance, strong alkali resistance, strong oxidant resistance, etc.; it has excellent electrical insulation properties, high voltage resistance, low high frequency loss, no moisture absorption, and high insulation resistance; it has excellent flame resistance, Aging performance and long service life.

GET A QUOTE

Product model:

- AFF/AFF 250

Implementation standard:

- Q/IRMV1-2008

Product Features:

1. Rated voltage: 300/500V

2. Working temperature: -60~+200℃/250℃

3. Conductor: stranded tin-plated or silver-plated copper wire

4. Insulation: FEP (200℃) or PFA (250℃) Teflon

5. Sheath: FEP (200℃) or PFA (250℃) Teflon

6. Color: red/yellow/blue/white/black/yellow-green/brown/green, etc.

Features/Uses:

It has excellent corrosion resistance, oil resistance, strong acid resistance, strong alkali resistance, strong oxidant resistance, etc.; it has excellent electrical insulation properties, high voltage resistance, low high frequency loss, no moisture absorption, and high insulation resistance; it has excellent flame resistance, Aging performance and long service life.

In the electronics industry, it can be used for temperature compensation wires, low-temperature resistant wires, high-temperature heating wires, aging-resistant wires and flame-retardant wires; in the household appliance industry, it can be used for air conditioners, microwave ovens, electronic disinfection cabinets, rice cookers, electronic hot water bottles, electric Internal wiring of heaters, electric ovens, electric woks, lighting fixtures, etc.

Delivery requirements:

According to the contractual agreement between the two parties, short-section delivery of not less than 10 meters is allowed. Its quantity should not exceed 10% of the total length of delivery.

Specification structure and technical parame

ters: AFF product technical parameters

| Number of cores×section (mm²) |

conductor structure Number of wires/ wire diameter (mm) |

insulation | jacket | ||

|---|---|---|---|---|---|

| insulation | outer diameter | outer diameter | outer diameter | ||

| 2 × 0.12 | 7/0.15 | 0.2 | 0.85 | 0.25 | 2.2 |

| 3 × 0.12 | 7/0.15 | 0.2 | 0.85 | 0.25 | 2.3 |

| 4 × 0.12 | 7/0.15 | 0.2 | 0.85 | 0.25 | 2.6 |

| 5 × 0.12 | 7/0.15 | 0.2 | 0.85 | 0.25 | 2.8 |

| 6 × 0.12 | 7/0.15 | 0.2 | 0.85 | 0.25 | 3.1 |

| 7 × 0.12 | 7/0.15 | 0.2 | 0.85 | 0.3 | 3.15 |

| 10 × 0.12 | 7/0.15 | 0.2 | 0.85 | 0.3 | 4 |

| 12 × 0.12 | 7/0.15 | 0.2 | 0.85 | 0.3 | 4.2 |

| 19 × 0.12 | 7/0.15 | 0.2 | 0.85 | 0.35 | 5 |

| 2 × 0.2 | 7/0.20 | 0.2 | 1 | 0.25 | 2.5 |

| 3 × 0.2 | 7/0.20 | 0.2 | 1 | 0.25 | 2.6 |

| 4 × 0.2 | 7/0.20 | 0.2 | 1 | 0.25 | 2.9 |

| 5 × 0.2 | 7/0.20 | 0.2 | 1 | 0.25 | 3.2 |

| 6 × 0.2 | 7/0.20 | 0.2 | 1 | 0.3 | 3.6 |

| 7 × 0.2 | 7/0.20 | 0.2 | 1 | 0.3 | 3.6 |

| 10 × 0.2 | 7/0.20 | 0.2 | 1 | 0.3 | 4.6 |

| 12 × 0.2 | 7/0.20 | 0.2 | 1 | 0.3 | 4.7 |

| 19 × 0.2 | 7/0.20 | 0.2 | 1 | 0.4 | 5.8 |

| 2 × 0.35 | 19/0.16 | 0.25 | 1.3 | 0.25 | 3.1 |

| 3 × 0.35 | 19/0.16 | 0.25 | 1.3 | 0.25 | 3.2 |

| 4 × 0.35 | 19/0.16 | 0.25 | 1.3 | 0.25 | 3.65 |

| 5 × 0.35 | 19/0.16 | 0.25 | 1.3 | 0.3 | 4.1 |

| 6 × 0.35 | 19/0.16 | 0.25 | 1.3 | 0.3 | 4.5 |

| 7 × 0.35 | 19/0.16 | 0.25 | 1.3 | 0.3 | 4.5 |

| 8 × 0.35 | 19/0.16 | 0.25 | 1.3 | 0.3 | 4.9 |

| 10 × 0.35 | 19/0.16 | 0.25 | 1.3 | 0.4 | 6 |

| 12 × 0.35 | 19/0.16 | 0.25 | 1.3 | 0.4 | 6.2 |

| 19 × 0.35 | 19/0.16 | 0.25 | 1.3 | 0.4 | 7.3 |

| 2 × 0.5 | 19/0.18 | 0.25 | 1.4 | 0.25 | 3.3 |

| 3 × 0.5 | 19/0.18 | 0.25 | 1.4 | 0.25 | 3.4 |

| 4 × 0.5 | 19/0.18 | 0.25 | 1.4 | 0.3 | 4 |

| 5 × 0.5 | 19/0.18 | 0.25 | 1.4 | 0.3 | 4.4 |

| 6 × 0.5 | 19/0.18 | 0.25 | 1.4 | 0.3 | 4.8 |

| 7 × 0.5 | 19/0.18 | 0.25 | 1.4 | 0.3 | 4.8 |

| 8 × 0.5 | 19/0.18 | 0.25 | 1.4 | 0.35 | 5.3 |

| 10 × 0.5 | 19/0.18 | 0.25 | 1.4 | 0.4 | 6.4 |

| 12 × 0.5 | 19/0.18 | 0.25 | 1.4 | 0.4 | 6.6 |

| 19 × 0.5 | 19/0.18 | 0.25 | 1.4 | 0.5 | 8 |

| 2 × 0.75 | 19/0.23 | 0.25 | 1.7 | 0.3 | 4 |

| 3 × 0.75 | 19/0.23 | 0.25 | 1.7 | 0.3 | 4 |

| 4 × 0.75 | 19/0.23 | 0.25 | 1.7 | 0.3 | 4.7 |

| 5 × 0.75 | 19/0.23 | 0.25 | 1.7 | 0.35 | 5.3 |

| 6 × 0.75 | 19/0.23 | 0.25 | 1.7 | 0.35 | 5.8 |

| 7 × 0.75 | 19/0.23 | 0.25 | 1.7 | 0.35 | 5.8 |

| 10 × 0.75 | 19/0.23 | 0.25 | 1.7 | 0.4 | 7.6 |

| 12 × 0.75 | 19/0.23 | 0.25 | 1.7 | 0.4 | 7.9 |

| 19 × 0.75 | 19/0.23 | 0.25 | 1.7 | 0.5 | 9.5 |

| 2 × 1 | 19/0.26 | 0.25 | 1.8 | 0.3 | 4.2 |

| 3 × 1 | 19/0.26 | 0.25 | 1.8 | 0.35 | 4.3 |

| 4 × 1 | 19/0.26 | 0.25 | 1.8 | 0.35 | 5.1 |

| 5 × 1 | 19/0.26 | 0.25 | 1.8 | 0.35 | 5.6 |

| 6 × 1 | 19/0.26 | 0.25 | 1.8 | 0.4 | 6.2 |

| 7 × 1 | 19/0.26 | 0.25 | 1.8 | 0.4 | 6.2 |

| 8 × 1 | 19/0.26 | 0.25 | 1.8 | 0.4 | 6.8 |

| 10 × 1 | 19/0.26 | 0.25 | 1.8 | 0.5 | 8.2 |

| 12 × 1 | 19/0.26 | 0.25 | 1.8 | 0.5 | 8.5 |

| 19 × 1 | 19/0.26 | 0.25 | 1.8 | 0.6 | 10.2 |

| 24 × 1 | 19/0.26 | 0.25 | 1.8 | 0.7 | 12.4 |

| 2 × 1.5 | 19/0.32 | 0.3 | 2.25 | 0.35 | 5.2 |

| 3 × 1.5 | 19/0.32 | 0.3 | 2.25 | 0.35 | 5.3 |

| 4 × 1.5 | 19/0.32 | 0.3 | 2.25 | 0.4 | 6.2 |

| 5 × 1.5 | 19/0.32 | 0.3 | 2.25 | 0.4 | 6.8 |

| 6 × 1.5 | 19/0.32 | 0.3 | 2.25 | 0.4 | 7.5 |

| 7 × 1.5 | 19/0.32 | 0.3 | 2.25 | 0.4 | 7.6 |

| 8 × 1.5 | 19/0.32 | 0.3 | 2.25 | 0.5 | 8.4 |

| 10 × 1.5 | 19/0.32 | 0.3 | 2.25 | 0.5 | 10 |

| 12 × 1.5 | 19/0.32 | 0.3 | 2.25 | 0.5 | 10.4 |

| 19 × 1.5 | 19/0.32 | 0.3 | 2.25 | 0.6 | 12.5 |

| 2 × 2.5 | 19/0.41 | 0.4 | 2.8 | 0.4 | 6.4 |

| 3 × 2.5 | 19/0.41 | 0.4 | 2.8 | 0.4 | 6.4 |

| 4 × 2.5 | 19/0.41 | 0.4 | 2.8 | 0.4 | 7.6 |

| 5 × 2.5 | 19/0.41 | 0.4 | 2.8 | 0.5 | 10.3 |

| 6 × 2.5 | 19/0.41 | 0.4 | 2.8 | 0.5 | |

Note: Other specifications can be customized according to needs

Also available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese