Differences between bare copper wire, tinned copper wire and copper clad aluminum wire

There are many types of copper wires on the market. Common ones can be divided into bare copper wire, tinned copper wire and copper clad aluminum wire. Bare copper wire is ordinary copper wire, also known as environmentally friendly copper wire. Many people are not very clear about the three types of copper wires. Let TST CABLES take you to understand.

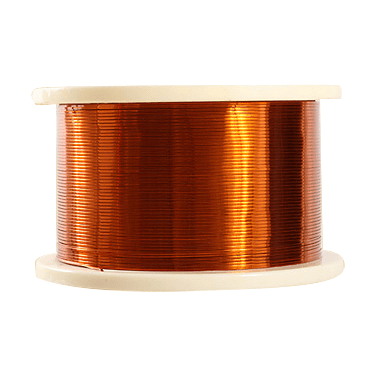

1. Bare copper wire

Bare copper wire is a copper wire made by drawing pure copper rods. It has a yellow appearance, a single material, copper metal inside and outside, and the color varies depending on the purity of copper. In terms of physical properties, bare copper wire is soft and has excellent conductivity.

2. Tinned copper wire

Tinned copper wire is made of 99.99% red copper as the core wire, and is made of hot-dip tin-based alloy; the product has the characteristics of bright appearance, uniform color, strong adhesion of the tin layer, and high oxidation resistance. Tinned copper wire is made by drawing pure copper rods into wires and then using hot-dip tinning technology to plate a thin layer of tin on the surface of the copper wire. Because tin is a silver metal, tinned copper wire generally appears silver in appearance. Tinning copper wire is mainly to prevent copper from being exposed to air and oxidized to form verdigris. Verdigris has poor conductivity and increases resistance. Tinned copper wire is relatively soft and has good conductivity. Compared with bare copper wire, it has stronger corrosion resistance and oxidation resistance, which can greatly extend the service life of weak current cables. In addition, tinning of copper wire can also prevent the insulating rubber from becoming sticky, the wire core from becoming black and brittle, and improve its solderability.

1. Composition: Copper core wire, coating is pure tin or lead-tin alloy.

2. Coating thickness: (h)

| Thickness Grade | Type I | Type II |

| Coating thickness | 3≤8 | 8≤12 |

3. Electrical conductivity:

At a temperature of 20℃

The electrical conductivity of diameters above 0.6mm is ≤0.0182Ωmm2/m

The electrical conductivity of diameters below 0.6mm is ≤0.0190Ωmm2/m

- Mechanical properties

| Diameter | Tensile strength N/mm2 | Elongation % | Repeated bending | |

| Load (g) | Number of times | |||

| 0.40 | >200 | >15 | 250 | 5 |

| 0.50 | >200 | >18 | 250 | 5 |

| 0.60 | >200 | >20 | 500 | 6 |

| 0.80 | >220 | >20 | 500 | 6 |

| 1.00 | >220 | >20 | 500 | 6 |

| 1.20 | >220 | >20 | 500 | 6 |

5. Solderability Conforms to SJ2422-83 standard

6. Application: Mainly used for leads of components such as resistors and capacitors

Product performance:

| Serial number | Items | Features |

| 1 | Appearance | The surface is bright and uniform in color, without tin peeling, black spots, cracks, burrs, yellowing, tin nodules and other abnormalities. |

| 2 | Wire diameter | Allowable deviation ±0.01mm. |

| 3 | Tin plating thickness | Thin plating: 1.5-2.5mm; medium plating: 2.5-4.0mm; thick plating: 4 mm or more |

| 4 | Elongation | ≥15% (or as required by customers) |

| 5 | Repeated bending | ≥4 times |

| 6 | Tensile strength | ≥245KG/mm2 |

| 7 | Weldability | 250±2℃ lead-free tin immersion for 2±0.5s, new tin can adhere to more than 95%. |

| 8 | Aging test | Baked at 200±5℃ for 1 hour, no yellowing or blackening. |

| 9 | Continuity | After three cycles of hydrochloric acid and sodium polysulfide solution testing, no copper exposure or black spots. |

| 10 | Binding strength | After winding more than 6 times and immersing in saturated sodium polysulfide, no cracks or blackening |

3. Copper clad aluminum wire

Copper clad aluminum wire usually adopts the cladding welding manufacturing technology, which concentrically clads the copper strip on the outer surface of the aluminum rod core wire, and forms a strong metallurgical bond between the copper layer and the core wire, so that the two different metal materials are combined into an inseparable whole, which can be drawn and annealed like processing a single metal wire. During the drawing process, the copper and aluminum change diameters in the same proportion, and the volume ratio of the copper layer remains relatively constant. Copper clad aluminum wire is very light, and compared with the previous two, its conductivity is much worse, its flexibility is not enough, it is easy to break, and its corrosion resistance and oxidation resistance are also relatively low.

Differences between bare copper wire, tinned copper wire, and copper clad aluminum wire

So, what are the differences and similarities between these three wires? Let’s take a look.

Appearance

Tinned copper wire is silver, bare copper wire and copper clad aluminum wire are purple. Just cut a section vertically and neatly, look at the cross section, if it is purple, it is copper wire; if it is white, it is copper clad aluminum wire.

Tool scraping

Tinned copper wire appears purple after scraping, bare copper wire remains purple, and copper-clad aluminum mesh appears white with snowflakes. The same effect can be achieved by rubbing the copper wire on a cement floor.

Fire test

Put the copper wire close to the flame. If it forms a ball-like object after burning, it is copper material; if the metal wire turns white after burning and droops and breaks when touched by hand, it is copper-clad aluminum mesh.

TST CABLES has been focusing on the production and processing of high-temperature cables such as copper-plated/nickel-plated/tin-plated for more than 20 years, and can produce red copper wire, tin-plated red copper wire, brass wire, phosphor bronze wire, chrome-zirconium copper wire, and mica wire. If you have customized copper/nickel/tin-plated high-temperature cables, DC cables, AC cables, low-smoke halogen-free cables, high-temperature cables, coaxial cables, UL cables, Teflon wires, armored wires, industrial cables, power cables, control cables and other products, and need further technical support or cable solutions, you can always send an email to the professional cable engineer of TST Cable Factory (email: lixiangchao@testeck.com, please state your country, your industry, and your needs in the email, we can provide you with free samples)

Also available in:

English