In the power industry, cables are important channels for transmitting electrical energy, so it is crucial to ensure cable safety. The installation of fire-blocking partitions or fire-blocking devices (also known as “fire-blocking sections” below) can effectively isolate the fire source when a fire occurs and protect the cables from fire.

According to the requirements of national standards GB50217 and GB50872, fire-blocking partitions, commonly known as “fire-blocking sections” in the industry, should be set at the following locations to minimize the impact of fire on cable trays. The installation locations include:

◆ The branch of the main channel of the cable bridge;

◆ The cable trench and tunnel section corresponding to the multi-section distribution device;

◆ The long-distance cable trench, tunnel and overhead bridge are about 100m apart, or the tunnel ventilation section;

◆ The entrance of the cable trench, tunnel and overhead bridge to the control room or distribution device, and the factory wall;

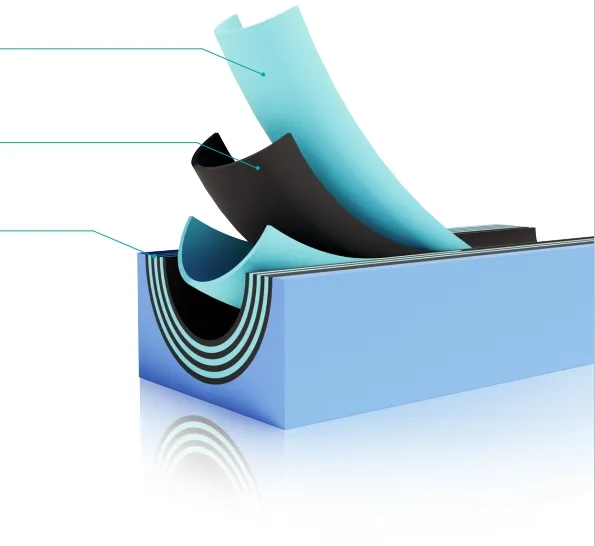

The light fire-blocking section is a product made of expanded flame-retardant materials, fire-proof cloth, metal components, etc. It can not only block the flame, but also has heat insulation performance. Its fireproof grade is 2h, GB23864 (2h heat insulation performance, 3h fire resistance integrity). As an alternative to traditional products, it has the characteristics of lightness, easy installation, and excellent fireproof performance. Installing it on the cable bridge solves the problem of complex disassembly of the traditional fire-proof base material flame-retardant section (box) when adding or reducing cables. There is no need to repeatedly apply and load and unload fire-proof bags, fire-proof mud and fire-proof boards, which is easy to maintain; it reduces the load-bearing capacity of the bridge, has higher strength and beauty, and has a long service life, saving maintenance costs.

It is widely used in cable tray fire isolation projects in power, rail transit, ships, petrochemicals, basic buildings, etc.

Application of light fire-blocking sections

In the power industry, light fire-blocking sections are mainly used in cable trays, because cable trays are important facilities for cable laying in the power industry. The application of fire-blocking sections can prevent the spread of fire in the vertical direction, buy time for personnel evacuation and fire fighting and rescue, and ensure the safety of equipment and personnel.

Technical advantages of light fire-blocking sections

- Lightness: Light fire-blocking sections are a standard product. Each type of bridge has corresponding standard specifications and is light in weight. The weight of a single set of products is no more than 5Kg, which is very conducive to inventory management and storage. This is very friendly to both early design and later installation.

- Fireproof and anti-corrosion performance: Light fire-blocking sections can work in harsh environments such as humid working conditions and high temperatures. According to GB23864, the fire protection level is ≧2h; the life is ≧20years. It has good fireproof performance and can effectively isolate the fire source when a fire occurs.

- High temperature resistance, conducive to heat dissipation: The light fire-blocking section can still maintain stable performance in high temperature environment. In the light fire-blocking section, the cable will not be completely wrapped by fire-proof mud, fire-proof bag, etc. like the traditional fire-blocking section. Its state is almost the same as the laying state in the bridge frame, which greatly reduces the risk of cable aging caused by heat accumulation in the traditional fire-blocking section.

- Easy installation, easy to add/replace cables: The upper cover plate and fire-proof fiber cloth of the product are openable structures. Adding or reducing cables will not damage the original structure, which brings many conveniences for later capacity expansion and maintenance. It can be installed before and after the cable is laid, and it is also very fast to add cables later. Under the premise of not destroying the product structure, for large specifications, you only need to peel off the Velcro, open the upper cover and put the cable in. For small specifications, you don’t even need to open the upper cover. Pass the cable through the light fire-blocking section and stick the Velcro again. Skilled workers can quickly complete the construction of the light fire-blocking section within 15 minutes, reducing the difficulty and cost of construction.

- Compliance with standards: Comply with GB50217-2018 “Design Standard for Cables in Power Engineering”, GB50872-2012 “Design Fire Protection Code for Hydropower Engineering”, GB23864-2009 “Fireproof Sealing Materials” and other standard documents.

The application of light fire-blocking sections in the power industry has significant advantages, which can effectively solve problems such as fire spread and cable aging, and ensure the safe operation of the power system. With the rapid development of my country’s power industry, light fire-blocking sections will play a greater role in the power industry in the future.

TST cables focuses on providing light fire-blocking sections and modular cable and pipe penetration and sealing system products for users in various industries, and provides customers with more suitable solutions with high-performance products and professional selection and after-sales services.

As an enterprise dedicated to the research and development and production of fireproof sealing products, it will make greater contributions to the safe development of my country’s power industry with more complete cable trays and fireproof sealing products.

If you want to learn more about TST cables cable and pipe penetration and sealing systems, you are welcome to contact TST CABLES by email at any time, and you can also get free samples and receive power industry application solutions and materials.

Also available in:

English