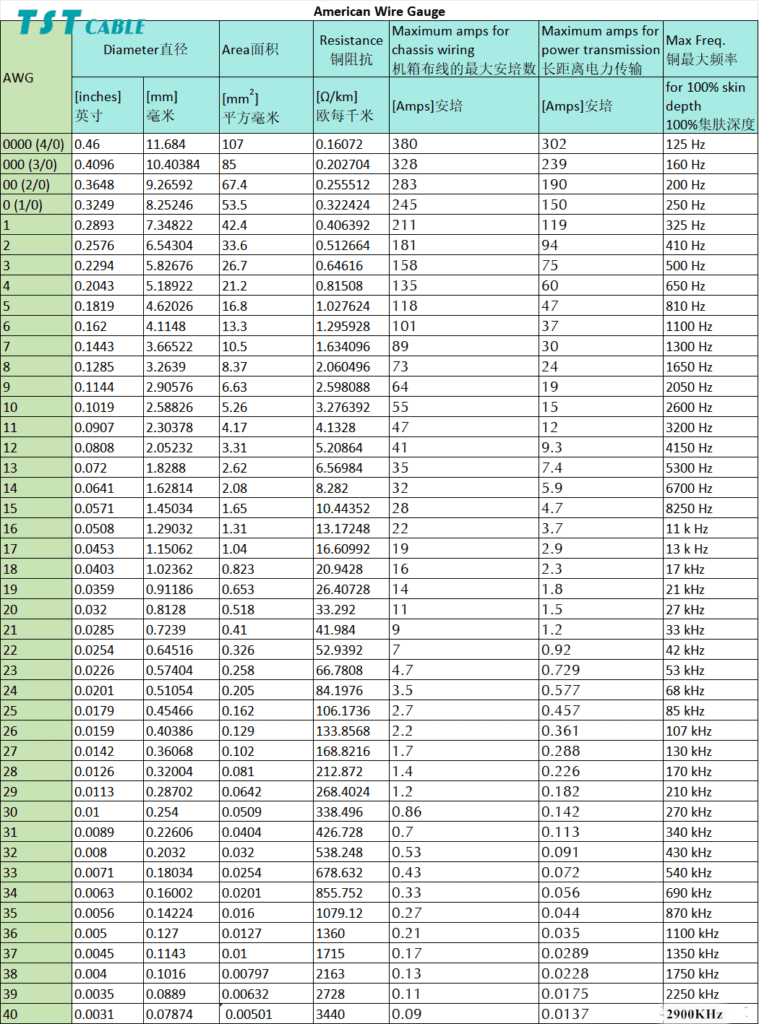

AWG (American Wire Gauge) and MCM (Thousands of Circular Mils) are two standards used to indicate wire size. They are mainly used to describe the cross-sectional area of the wire, but use different units and conversion methods

AWG (American Wire Gauge)

AWG is a logarithmic scale system, and the wire diameter is reduced by about half for every 3 AWG numbers.

AWG 0 (also written as 1/0 or called “aught”) represents a larger wire size, and the larger the number, the thinner the wire.

MCM (Thousand Circular Mils)

MCM stands for “Thousand Circular Mils”, where 1 circular mil is equal to the area of a circle with a diameter of 1 mil (one thousandth of an inch).

For larger wire sizes, MCM is usually used to indicate, such as 250 MCM, 350 MCM, etc.

Conversion method

For smaller wire sizes, AWG is usually used; for larger wire sizes, MCM may be used. The conversion between the two can be done in the following ways:

Direct lookup table: The easiest way is to use a readily available AWG to MCM comparison table. These tables list the cross-sectional area (in MCM) corresponding to different AWG specifications.

Calculation formula:

If you need to calculate instead of look up, you can use the following formula to convert AWG to MCM:

Diameter (mil) = 5761/(92)(36−AWG)/19Diameter (mil) = 5761/(92)(36−AWG)/19 Then use this diameter to calculate the cross-sectional area (in square mils), and finally divide by 1000 to get the MCM value.

Or it is easier to use the approximate formula for estimation: Area in circular mils = 92 (36-AWG) / 39 × 1000 Area in circular mils = 92 (36-AWG) / 39 × 1000 Common conversions: For example, 4/0 (AWG 0000) is equivalent to 211.6 MCM. AWG 1000 kcmil (or 1000 MCM) is equivalent to approximately 4/0 AWG. Please note that for very large or very small wire sizes, the actual application may exceed the standard AWG range. In this case, MCM or other units such as square millimeters (mm²) will be used directly. In actual engineering applications, it is usually recommended to refer to specific product manuals or industry standard documents, because the data provided by the manufacturer is the most accurate and reliable. In addition, some professional tools and software can also help to quickly complete this conversion.

Below is a simplified conversion table between AWG (American Wire Gauge), MCM (Thousands of Circular Mils) and metric units (square millimeters, mm²). Please note that the actual values may vary slightly, and the data provided by the cable manufacturer TST CABLES or the official standards should be referred to for specific applications.

AWG MCM (kcmil) mm² (approximate)

| AWG | MCM (kcmil) | mm² (approximation) |

| 4/0 (0000) | 211.6 | 107 |

| 3/0 (000) | 167.8 | 85.0 |

| 2/0 (00) | 133.1 | 67.4 |

| 1/0 (0) | 105.5 | 53.5 |

| 1 | 83.7 | 42.4 |

| 2 | 67.4 | 33.6 |

| 3 | 53.5 | 26.7 |

| 4 | 42.4 | 21.2 |

| 5 | 33.6 | 16.8 |

| 6 | 26.7 | 13.3 |

| 8 | 16.5 | 8.37 |

| 10 | 10.4 | 5.26 |

| 12 | 6.53 | 3.31 |

| 14 | 4.11 | 2.08 |

| 16 | 2.58 | 1.31 |

| 18 | 1.62 | 0.820 |

| 20 | 1.02 | 0.511 |

For larger wire sizes, MCM is often used, and here are a few common examples:

250 MCM ≈ 126.7 mm²

300 MCM ≈ 151.1 mm²

350 MCM ≈ 175.6 mm²

400 MCM ≈ 200.0 mm²

500 MCM ≈ 250.0 mm²

600 MCM ≈ 298.1 mm²

700 MCM ≈ 348.4 mm²

750 MCM ≈ 377.0 mm²

800 MCM ≈ 400.0 mm²

1000 MCM ≈ 500.0 mm²

Please note that these conversions are approximate and may vary slightly in different literature. When performing critical design or engineering calculations, always confirm that the conversion tables used are up to date and in accordance with local codes and standards. If more precise values or specific application recommendations are required, the technical manual of the relevant cable product or the manufacturer should be consulted.

In addition to the above conversion tables between AWG, MCM and metric units (square millimeters, mm²), there are some additional information and notes to help you better understand and apply these conversions.

1. Circular Mil:

Circular mil is a commonly used unit of wire cross-sectional area in the United States, defined as the area of a circle with a diameter of 1 mil (0.001 inches). Its advantage is that it does not require the use of π to calculate the circular area, because for any circle with a diameter of D mils, its area A is D^2 circular mils.

2. Thousand circular mil (kcmil or MCM):

When the wire size exceeds 4/0 AWG, it is usually expressed in thousands of circular mils (MCM). For example, 250 kcmil means that the cross-sectional area of the wire is equal to 250,000 circular mils.

3. Conversion formula:

The conversion from circular mil to square millimeter can be done with the following formula:

mm² = circular mil

1973.5

Conversely, the conversion from square millimeter to circular mil can be done with this formula:

Circular mil = mm² * 1973.5

Notes

Standard differences: Different countries and regions may have different wire size standards. For example, in Europe, the IEC standard is more commonly used; while in North America, AWG and MCM are more common. Therefore, special attention needs to be paid to this in multinational projects.

Temperature coefficient: The resistivity of the wire changes with temperature, which affects the selection of the wire. Make sure to consider the maximum temperature in the working environment and the safe current carrying capacity of the wire.

Mechanical strength: When selecting the wire size, not only the electrical performance but also the mechanical strength should be considered. Especially in outdoor or industrial environments, the wire may be affected by physical stress.

Installation method: The laying method of the wire (such as direct burial, overhead, in pipeline, etc.) will also affect its heat dissipation effect, and thus affect the current carrying capacity. Under different installation conditions, the same size of wire may have different rated currents.

Cost-Benefit Analysis: While larger conductors can reduce voltage drop and improve efficiency, they also cost more. Therefore, when designing a power system, a cost-benefit analysis should be performed to find the optimal conductor size.

Practical Application Recommendations

Consult manufacturer information: For specific engineering projects, you should consult the technical manual or data sheet provided by the cable manufacturer to obtain the most accurate product specifications and recommended conditions of use.

Follow local regulations: Make sure that all conductor size selections comply with local electrical installation regulations and safety standards, such as NEC (National Electrical Code), CEI (Italian Electrotechnical Commission), or other applicable standards.

Consider future development: When selecting conductor size, consider the possible increase in load requirements in the future and reserve a certain margin to facilitate system expansion and upgrades.

By considering the above factors, you can make a more informed choice and ensure that the selected conductor can meet current needs and adapt to possible changes in the future. If you have specific application scenarios or questions, please continue to ask questions and I will try my best to help.

Attachment: Latest AWG/MCM wire gauge metric conversion table in 2025.png

Also available in:

Arabic

English

Japanese

Russian

Portuguese (Brazil)