Are you looking for a Flat Flexible Cable ffc manufacturer that can operate stably at high temperatures of 200℃~1200℃? TST cable will show you the characteristics, applications and technology development trends of flexible cables.

Introduction to Flat Flexible Cable ffc

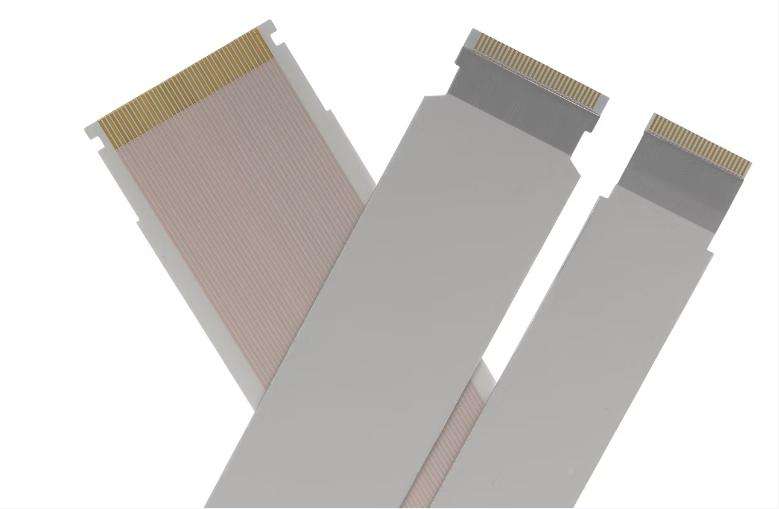

Flat Flexible Cable ffc (FFC), sometimes also called Flexible Printed Circuit (FPC), is a flat cable made of a multi-strand copper wire conductor wrapped with insulating material and pressed by a high-tech automated equipment production line through a sheath material. It has the advantages of softness, free bending and folding, relatively thin thickness, small size, simple connection, easy disassembly, etc. The number and spacing of wires can be arbitrarily selected to make wiring more convenient, greatly reduce the volume of the product, reduce production costs, and improve production efficiency. It is suitable for data transmission cables or power transmission in electrical equipment. Common specifications include 0.5mm, 0.8mm, 1.Omm, 1.25mm, 1.5mm, 2.0mm, 2.5mm and other flexible cables with various spacings. The design of FFC allows it to bend and fold in a small space, which is very suitable for use in environments that require frequent movement or limited space.

Flat Flexible Cable ffcs are used for power connections and control signal lighting of various mobile power devices in industries such as lifting, transportation, machinery, electrical, mining, etc. with working voltages below 450/750V and ambient temperatures of -70~260℃.

It has the following characteristics: Nitrile compound is used for insulation and sheath. Improve the softness and corrosion resistance of the cable. TST CABLES can customize various specifications of Flat Flexible Cable ffcs according to customer needs, and add steel wire ropes or other load-bearing elements on both sides of the core.

The wide application of FFC cables is due to its light, flexible, efficient transmission characteristics, and ability to adapt to complex space and mobile needs. With the continuous advancement of technology, FFC will continue to play a key role in more innovative fields.

Advantages of Flat Flexible Cable ffcs

Light, thin and compact: FFC takes up little space, is light in weight, and is suitable for layout in limited spaces.

High flexibility: Able to withstand multiple bends, suitable for connecting components that require frequent movement.

Cost-effectiveness: Compared with traditional round cables, FFC can reduce costs and simplify the assembly process in some applications.

Signal integrity: In high-frequency signal transmission, FFC can provide good signal integrity and low signal loss.

Easy to design and integrate: The shape and size can be customized according to specific needs, which is convenient for integration into various electronic devices.

Flat Flexible Cable ffc (FFC) structure and materials

Flat Flexible Cable ffc (FFC) materials and structure

The main materials of FFC cable include conductor, insulation layer and protective layer. The basic structure of FFC consists of conductor layer and insulation layer, where the conductor layer can be single layer or multi-layer, and the insulation layer is wrapped around the outside of the conductor layer to form a flat cable structure. In some high-performance FFCs, additional shielding layers and reinforcement layers may also be included to provide better electromagnetic compatibility (EMC) and mechanical protection.

Conductor layer: Usually a thin wire made of copper, used to transmit electrical signals. The thickness and width of the conductor layer can be customized according to different application requirements.

Insulation layer: Covering on the conductor layer, it plays the role of electrical isolation to prevent short circuit. Common insulating materials include polyimide, polyester (PET), polyvinyl chloride (PVC), etc.

Protective layer: In some FFCs, there is an additional protective film to increase the mechanical strength and durability of the cable and protect the conductor and insulation layer from external damage.

Connector: Both ends of the FFC are usually equipped with special connectors for connecting to the motherboard or other circuit boards of electronic devices for quick plugging and unplugging.

Conductor material: The most commonly used is copper, especially high-purity oxygen-free copper (OFC), because of its good conductivity and flexibility. The conductor is usually in the form of multiple strands of fine copper wires twisted together to enhance the softness and tensile strength of the cable.

Insulation layer material:

Polyimide: It has excellent thermal stability, chemical stability and mechanical strength, and is suitable for high temperature environments.

Polyester (PET): It has low cost and is suitable for medium temperature and non-extreme environments.

Polyvinyl chloride (PVC): It is used in some non-high temperature applications, such as internal connections of household appliances.

Silicone: It has good heat resistance and flexibility, and is suitable for occasions requiring high flexibility and temperature resistance.

Protective layer material: usually polyimide or polyester film, sometimes rubber or silicone is used to increase the mechanical strength and environmental resistance of the cable.

Flat Flexible Cable ffc (FFC) temperature range

The temperature range of Flat Flexible Cable ffc (FFC) mainly depends on the selected insulation material and protective layer material. For example:

Polyimide cable (Polyimide): The operating temperature range is usually -55°C to +200°C or above, and some special grades can reach +260°C.

Polyester cable (PET): The operating temperature range is about -40°C to +105°C.

Polyvinyl chloride cable (PVC): The operating temperature range is usually around -20°C to +80°C.

Silicone cable (Silicone): The operating temperature range is wide, usually -60°C to +200°C, or even higher.

Application field of Flat Flexible Cable ffc

FFC is widely used in many fields due to its unique advantages:

Consumer electronics: such as mobile phones, tablets, laptops, digital cameras, etc., used for connection between internal components.

Medical equipment: In medical equipment that requires high precision and miniaturization, such as endoscopes, wearable medical devices, etc., FFC can provide reliable signal transmission.

Automotive electronics: In modern cars, FFC is used for internal connections such as dashboards, navigation systems, entertainment systems, etc. to save space and reduce weight.

Industrial automation: In scenarios such as automation equipment, robots, sensor networks, etc., FFC can provide flexible data and power transmission.

Aerospace: In aerospace equipment that requires extreme reliability and lightweight, the thinness and flexibility of FFC make it an ideal choice.

Wearable technology: Internal wiring of smart watches, fitness trackers, virtual reality (VR) and augmented reality (AR) devices.

Flat Flexible Cable ffc design and manufacturing

The design and manufacturing of FFC involves precise processes, including conductor calendering, insulation coating, cutting, stamping, welding connectors and other steps. With the advancement of technology, the manufacturing process of FFC has gradually been automated and standardized, improving production efficiency and product quality.

Latest progress and future trends of Flat Flexible Cable ffcs (FFC/FPC)

Latest progress

Material innovation: The development of new materials has given FFC better heat resistance, chemical resistance and higher mechanical strength, broadening its application range in harsh environments.

Integration improvement: With the development of microelectronics technology, FFC is not just a simple conductive path, but integrates more functions, such as embedded sensors, antennas, etc., becoming an indispensable part of smart devices.

Ultra-thin and miniaturization: By improving the manufacturing process, FFC has become thinner and narrower, suitable for more complex and compact electronic devices.

Application of environmentally friendly materials: Considering environmental protection and sustainability, more and more FFCs use recyclable or biodegradable materials to reduce the impact on the environment.

Future trends

Integration of flexible display technology: With the development of flexible display screens, FFC will be more used to connect flexible screens and motherboards to realize truly foldable and bendable electronic devices.

Internet of Things and 5G technology: Driven by the Internet of Things and 5G communication technologies, FFC will carry higher frequency and larger bandwidth signal transmission, and put forward higher requirements for signal integrity.

Smart Manufacturing and Automation: In Industry 4.0 and automated production lines, the demand for FFC will continue to grow, especially in sensor networks, robotic arms and other application scenarios.

Expansion of Biomedical Applications: FFC will be more widely used in the biomedical field, such as implantable medical devices, biomonitoring sensors, etc., requiring FFC to have higher biocompatibility and safety.

Personalization and Customization: With the advancement of 3D printing technology, personalized customization of FFC will become possible to meet specific design and functional requirements.

As a key technology for internal connection of electronic devices, Flat Flexible Cable ffcs (FFC/FPC) are ushering in new development opportunities with the continuous advancement of science and technology. Whether it is material innovation, increased integration, or enhanced environmental awareness, it indicates that FFC will play a more important role in the future electronics industry. With the rise of emerging technologies such as the Internet of Things, 5G, and smart manufacturing, the application scenarios of FFC will be broader and become a bridge connecting the future smart world.

The FFC cable developed by cable manufacturer TST cables uses high-quality oxygen-free copper conductors and high-performance polyimide insulation layers to ensure the stability and efficiency of signal transmission. The wide operating temperature range, from -60°C to +260°C, can easily cope with various extreme environmental challenges.

Each FFC cable undergoes strict quality control, from material screening to finished product testing, every step is refined. TST cables has world-class production equipment and a professional technical team to ensure product consistency and reliability.

TST cables provides personalized customization services. No matter what specifications, sizes or special functions you need, we can tailor them according to your needs to ensure that FFC perfectly fits your equipment and achieves free, stable and efficient connection.

If you have any questions, needs or want to get free samples of high-temperature cables for flexible cables, you can contact us by email or phone at any time.

Also available in:

English