Huge Temperature Range

-200℃~+1200℃

- Customized Design Production

Small MOQ

Short Lead Time

- Long Time Guarantee

- Home

- /

- High Temperature Cable Heat...

High temperature cable | heat resistant cable (-200℃~+1200℃)

High temperature cable (heat resistant cable) is a type of cable specially designed to cope with extreme high temperature environments. They are able to operate at higher temperatures without affecting their electrical and physical properties. High-temperature cables are widely used in various industrial environments, such as electric power, petroleum, chemical industry, aerospace and other fields.

The insulation material of ordinary cables is easy to soften or melt at high temperatures, resulting in reduced electrical performance, signal interruption, and even short circuits; secondly, its flame retardant properties are poor, and it is easy to burn under high temperatures or fire conditions, aggravating the spread of fire; in addition, ordinary cables The mechanical strength of cables is low and they are easily deformed or broken at high temperatures, affecting their service life.

Finally, ordinary cables are susceptible to chemical corrosion in high temperature environments, causing the insulation layer to age and shortening the overall life of the cable. Therefore, in high-temperature applications, the use of high-temperature cables can significantly improve the safety and reliability of the system.

Below, TST CABLES will introduce you to the characteristics, materials, applications and standards of high-temperature cables in detail.

1. High temperature cables. Advantages of heat resistant cables

High temperature resistance: Able to work in high temperature environments for long periods of time, usually ranging from 100°C to 250°C or even higher (up to 1200°C).

- Chemical resistance: Many high-temperature cable materials have good chemical resistance.

- Abrasion Resistance: The outer material tends to be stronger and resist wear and tear.

- Flexibility: Certain types of high-temperature cables maintain strength while also being flexible, making installation easier.

- Low-smoke halogen-free flame retardant properties: Some high-temperature cables have low-smoke halogen-free flame retardant properties, which can delay the spread of fire under fire conditions.

- Anti-EMI electromagnetic interference: High-temperature cables are designed with anti-interference requirements in mind and adopt a variety of technical means, such as twisted pair structure, multi-layer shielding, etc., to further improve anti-interference capabilities and improve the reliability and reliability of signal transmission. accuracy.

2. High temperature cables and heat resistant cable materials

In order to maintain stable working performance under extreme temperatures, high-temperature cables usually use a series of special materials to make conductors, insulation layers and sheaths. The selection of these materials depends on the cable’s operating environment, temperature range, chemical stability needs, and mechanical strength requirements. Here are several common high-temperature cable materials and their uses:

2.1 High temperature cable conductor materials

Copper (Cu): is one of the most commonly used conductor materials because of its good electrical conductivity and high heat resistance.

Silver-plated copper (Ag-Cu): Silver plating can increase the oxidation resistance of the conductor and is suitable for cables working at high temperatures.

Nickel Alloy (Ni): Nickel alloy conductors can provide better durability and conductivity under certain extreme conditions, such as high temperatures and corrosive environments.

2.2 High temperature cable insulation materials

Fluoroplastic cables (such as PTFE, FEP, PFA):

Polytetrafluoroethylene (PTFE) cable: It has extremely high temperature resistance (up to 260°C), and has very good chemical stability and is not easily corroded by most solvents.

Fluorinated Ethylene Propylene Copolymer (FEP) Cable: Similar to PTFE, but has better processing properties and is suitable for applications that require bending and forming.

Perfluoroalkoxy (PFA) cable: has better mechanical properties and higher transparency than PTFE, suitable for applications requiring high transparency and high temperature resistance.

Silicone rubber cable: soft and with good temperature resistance (up to 200°C), suitable for applications requiring flexibility, such as engine compartment wiring in the automotive industry.

Mica Tape Cable: Usually used in combination with other insulating materials, it can withstand very high temperatures (up to 800°C) and is suitable for electrical connections in extremely high temperature environments.

Polyetheretherketone (PEEK) cable: It is a high-performance engineering plastic with excellent high temperature resistance, chemical stability and mechanical strength.

Polyimide (PI) cable: It is a high-temperature resistant insulating material that is widely used in electrical and electronic equipment in high-temperature environments and is known for its excellent heat resistance and electrical insulation properties.

2.3 High temperature cable sheath material

Fluoroplastics (PTFE, FEP, PFA): Like insulation materials, these materials are also commonly used in jacketing to provide additional protection.

- Silicone Rubber: Also suitable for sheath materials, providing high temperature resistance and flexibility.

- Polyamide (Nylon): Used as a sheath material in some cases, it has good wear resistance and mechanical strength.

- Polyurethane (PU): Has good abrasion and chemical resistance and is suitable for environments that require additional protection.

Other high temperature cable auxiliary materials

- Glass Fiber: Usually used in combination with silicone rubber or other insulating materials to enhance the mechanical strength and temperature resistance of the cable.

- Ceramic Fiber: used in extreme high temperature environments and can withstand temperatures up to 1000°C or more.

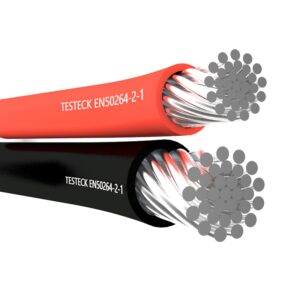

2.4 Composite high temperature cable materials

In some special applications, a combination of materials, such as a composite of mica tape and silicone rubber, or a composite of fluoroplastic and glass fiber, may be used to achieve the best temperature resistance, insulation and mechanical protection effects.

3. High temperature cable application fields

3.1. Aerospace

Engine cabin wiring: Cables in the aircraft engine cabin need to withstand high temperatures and vibrations, and high-temperature cables can work stably in such an environment.

- Sensor connection: Various sensors (such as temperature sensors, pressure sensors) installed in high-temperature areas need to be connected using high-temperature cables.

- Radar and communication systems: Radar and communication systems on aircraft need to maintain the quality of signal transmission in high-temperature environments, and high-temperature cables can provide reliable electrical connections.

3.2. Automobile industry

Engine compartment wiring: The temperature in the automobile engine compartment can reach more than 120°C, and high-temperature cables can maintain electrical performance in this environment.

- Battery Management System (BMS): The battery management system in electric vehicles requires the use of high-temperature cables to connect the battery pack and control system to ensure reliability under high-temperature conditions.

- Exhaust system: Cables near the automobile exhaust system need to be resistant to high temperatures, and high-temperature cables can meet this need.

3.3. Petrochemical industry

Heating furnaces and reactors: In high-temperature equipment such as heating furnaces and reactors, high-temperature cables are used for electrical connections to ensure the normal operation of the equipment under high-temperature conditions.

- Sensors and instruments: Various temperature sensors, pressure sensors and other instrument equipment need to be connected using high-temperature cables.

- Control and signal transmission: In chemical plants, high-temperature cables are used for control and signal transmission to ensure the reliability of the control system in high-temperature environments.

3.4 The difference between LSZH cable and ordinary PVC cable

In terms of physical properties, LSZH and ordinary PVC cables are very different. PVC jumpers are softer, while LSZH jumpers are harder and contain flame retardant compounds. LSZH cables are more beautiful and safer.

PVC cables are made of polyvinyl chloride, and their sheaths release thick black smoke and hydrochloric acid when burned. Unlike PVC cables, LSZH cables have fireproof sheaths, superior flame retardant properties, very little smoke when burning, and no corrosive gas escapes.

Reduce toxic and corrosive gases produced during combustion, and protect personnel and equipment from harm.

3.5 Power transmission

Substations and power plants: High-temperature cables are used for electrical connections within substations and power plants, especially in high-temperature equipment such as transformers and switchgear.

High-voltage transmission lines: In high-voltage transmission lines, high-temperature cables can be used to connect various electrical equipment to ensure stable operation under high-temperature conditions.

3.6 Metallurgical industry

High-temperature furnaces and smelting equipment: In the metallurgical industry, high-temperature cables are used to connect various high-temperature furnaces and smelting equipment to ensure electrical performance in high-temperature environments.

Automated control system: The automated control system on the metallurgical production line requires the use of high-temperature cables to connect various control units to ensure normal operation under high-temperature conditions.

3.7 Medical equipment

Surgical equipment: In the operating room, high-temperature cables are used to connect various surgical equipment to ensure electrical performance during high-temperature sterilization.

Diagnostic instruments: In medical diagnostic instruments, high-temperature cables are used to connect various sensors and controllers to ensure signal transmission quality in high-temperature environments.

3.8 Railway cable

Train electrical system: The train electrical system in rail transit requires the use of high-temperature cables to connect various components to ensure electrical performance under high-temperature conditions.

Signaling and communication systems: Signaling and communication systems in rail transit need to be connected using high-temperature cables to ensure signal transmission quality in high-temperature environments.

3.9 Semiconductor manufacturing

Wafer processing equipment: In the semiconductor manufacturing process, wafer processing equipment requires the use of high-temperature cables to connect various components to ensure electrical performance under high-temperature conditions.

Clean room environment: In clean rooms of semiconductor manufacturing, high-temperature cables are used to connect various equipment to ensure electrical performance and reliability in high-temperature environments.

3.10 New energy

Solar power generation: In solar power generation systems, high-temperature cables are used to connect photovoltaic panels and inverters to ensure electrical performance under high-temperature conditions.

Wind power generation: In wind power generation systems, high-temperature cables are used to connect generators and control systems to ensure electrical performance under high-temperature conditions.

3.11 Scientific research laboratory

High temperature experimental equipment: In scientific research laboratories, high temperature cables are used to connect various high temperature experimental equipment to ensure electrical performance under high temperature conditions.

Testing instruments: In high-temperature testing instruments, high-temperature cables are used to connect various sensors and controllers to ensure signal transmission quality in high-temperature environments.

4. High temperature cable testing standards

High-temperature cables need to undergo a series of rigorous tests before production and use to ensure their performance and safety under high temperatures and other harsh conditions. These tests are usually conducted in accordance with international and national standards and cover many aspects such as electrical properties, mechanical properties, temperature resistance and flame retardant properties. Here are some common high temperature cable testing standards:

4.1. International Electrotechnical Commission (IEC) standards

- IEC 60227: Applicable to polyvinyl chloride insulated cables with rated voltages of 450/750V and below. Although it is not specifically targeted at high-temperature cables, some test items are also applicable to high-temperature cables.

- IEC 60245: Applicable to rubber insulated cables with rated voltages of 450/750V and below. It also includes some tests applicable to high-temperature cables.

- IEC 60331: Specifies the integrity test of cables under fire conditions to ensure that the cable can still maintain functionality for a period of time in a fire.

- IEC 60332 series: Covers a series of test methods for the flame retardant performance of cables, including flame propagation testing of single cables, flame propagation testing of bundled cables, etc.

- IEC 60332-3: Flame propagation test of bundled cables, simulating the behavior of cable bundles in a fire.

- IEC 60332-1: Flame propagation test of single insulated wire and cable.

- IEC 60332-3-22: Vertical bracket combustion test of bundled cables to evaluate the behavior of cable bundles in flames.

4.2. Underwriters Laboratories (UL) standards

- UL 1581: This is a widely recognized standard that covers a variety of cable tests, including flame retardant testing (such as VW-1 testing), heat resistance testing, oil resistance testing, etc.

- UL 1332: Applicable to cables used in high temperature environments, stipulating the heat resistance and other related characteristics of the cable.

- UL 1581 VW-1: Vertical Bracket Burning Test, used to evaluate the flame retardant performance of individual cables.

4.3. European Standard (EN)

- EN 50575: This standard specifies the performance classification of cables in fire, including smoke density, flame propagation speed and other indicators.

- EN 50399: Specifies the performance test methods of cables under fire conditions, including combustion test, smoke density test, etc.

4.4. Chinese National Standard (GB)

- GB/T 18380.11: Similar to IEC 60332-1, it specifies the flame propagation test of single insulated wires and cables.

- GB/T 18380.22: Similar to IEC 60332-3-22, specifies the vertical bracket burning test for bundled cables.

- GB/T 18380.23: Specifies the horizontal bracket burning test for bundled cables.

- GB/T 18380.31: Specifies the flame propagation test method for cables.

- GB/T 18380.32: Specifies the flame propagation test method for cables, applicable to cables with special requirements.

5. High temperature cable test content

The testing of TST CABLES high-temperature cables usually includes the following aspects:

Temperature resistance test: Test the performance of the cable at different temperatures to ensure that it can still maintain electrical performance under high temperature conditions.

Flame retardant test: Evaluate the performance of the cable in flames to ensure that it can delay the spread of fire.

Mechanical performance testing: including bending test, tensile test, etc. to ensure that the cable can withstand certain mechanical stress during installation and use.

Electrical performance testing: Test electrical parameters such as cable resistance, insulation resistance, and withstand voltage to ensure its electrical performance in high-temperature environments.

Through these test standards, high-temperature cables can meet the requirements for use in various industrial environments, ensuring their safety and reliability under high temperatures and other harsh conditions. When selecting and purchasing high-temperature cables, it is very important to understand and comply with the appropriate testing standards.

6. Cooperate with cable supplier TSTcables to customize high quality high temperature cables

Chinese high temperature cable manufacturer TST Cable reminds customers that customized cables (-260℃, -200℃, -95℃, 70℃, 90℃, 105℃, 135℃, 200℃, 250℃, 260℃, 400℃, 900 ℃, 1000℃, 1100℃, 1200℃), the selection and application of high temperature cables, low temperature cables, flame-retardant cables, and fire-resistant cables are not only related to the matching of technical performance, but also need to consider the operating temperature range, installation conditions and environment of the equipment, Comprehensive factors such as transportation conditions, construction, after-sales, ecological environmental impact, safety regulations and future development trends ensure that while meeting the current and future actual needs of the enterprise, it also contributes to the sustainable development of human ecological and environmental protection.

TSTcables high temperature resistant cables use top materials and insulation technology to easily cope with the challenges of extreme high and low temperature environments of -260°C to 1200°C. Their excellent thermal stability and flame retardant properties protect your industrial heart. From deep mines to fiery furnaces, from cutting-edge technology laboratories to exploration of the vast universe, we use our ingenuity to endow cables with extraordinary toughness and intelligent potential. Stably transmitting power in the harshest ultra-high temperature environments, TSTCABLES innovative technology injects inexhaustible power into cutting-edge fields such as petroleum, aerospace, medical, marine, and military, guarding and supporting every dream that challenges the limits. If you have customized cable needs for high-temperature cables, please feel free to contact our engineers by email or phone (lixiangchao@testeck.com) and we can also provide free samples.

Related by TST:

Comparison between rail transit cables and other cables

With the development of high-speed railways and urban rail transit,...

Read MoreSelection Guide for Fire Resistant Power Cables

Fire-resistant power cables are cables specially designed to maintain normal...

Read MoreCross linked polyethylene cable (XLPE) deciphers the heat resistance code of rail transit cables

The rapid development of rail transit has put forward higher...

Read MoreHow to choose lszh cable railway cable subway fireproof soft cable

Subway fireproof soft cable is a cable designed to meet...

Read MoreAlso available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese

Portuguese (Brazil)