Do you know what are the uses of flat cables and ribbon cables? TST CABLES introduces the common specifications, uses and advantages of flat cables and ribbon cables in detail.

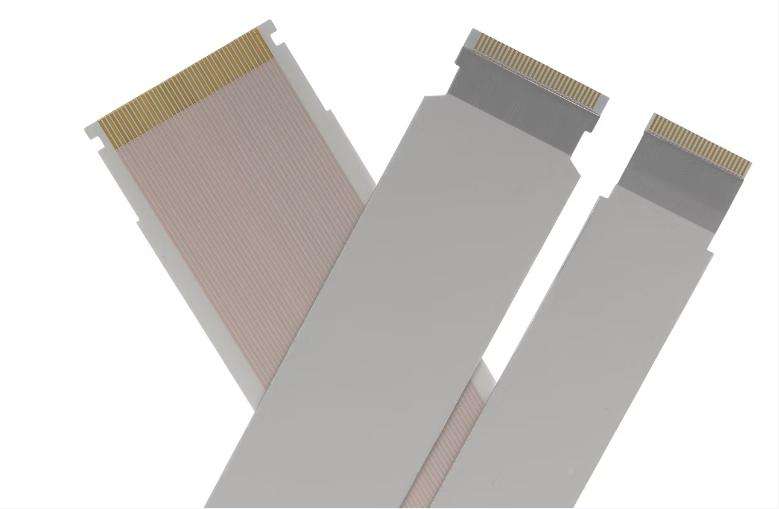

Ribbon cable, ribbon cable (Ribbon Cable), also known as flat cable, rainbow cable, flat flexible cable, etc. (ffc cable, flat cable, flat flexible cable), is a cable composed of multiple parallel wires, usually fixed on a flat insulating substrate. It refers to a cable with multiple wires with flat broadband. Ribbon cable is suitable for connecting electronic appliances, instruments, computers and other control equipment.

The wire and cable industry uses various terms to describe this type of cable, including: ribbon cable, flat cable, flat flexible cable, flat cable, multi-wire flat cable, flat flexible cable, twisted flat cable, braided cable. The concept of ribbon cable is very simple, but its implementation is different. Flat conductor ribbon cable can complete special tasks that ordinary round cables cannot complete.

Ribbon cable conductors are made of a variety of metals, such as copper, aluminum, steel, nickel and other alloys. Among them, copper and aluminum are the most commonly used. The conductor of the round conductor ribbon cable can be composed of a single or 7 strands, and the flat conductor can be made of copper foil cut or flattened from a round wire of the corresponding cross section. In cases where sufficient adhesion between the plastic and the metal conductor is required, black oxidized copper conductors can be used, and in some special cases, brass, bronze, silver or stainless steel can also be used as conductors.

Structure, materials and advantages of ribbon cables

How are flat ribbon cables made? What is the structure?

Conductor: The conductors in ribbon cables can be flat or round. Flat conductors are usually used in flat conductor ribbon cables, while round conductors are used in round conductor ribbon cables. The number of conductors can range from a few to dozens, depending on the specific application requirements.

Insulation layer: The conductor is coated in an insulating material to prevent electrical short circuits. Commonly used insulating materials include polyester (PET), polyimide (PI), polyvinyl chloride (PVC) or Teflon (PTFE), etc.

Support material: Sometimes additional support materials are added between or outside the insulation layers to enhance the physical strength and stability of the cable and prevent the cable from deforming during use.

Jacket: The outermost layer is usually a protective jacket, which can be flexible or semi-rigid, depending on the environment in which the cable is used. The jacket material can be polyester, polyurethane (PU), polyvinyl chloride (PVC) or other weather-resistant materials, providing water resistance, oil resistance, chemical corrosion resistance and abrasion resistance.

Features of ribbon flat cable:

Flat structure: Ribbon cables have a flat shape, which allows them to fit into narrow spaces and are easy to route between circuit boards.

Multi-wire parallel: The cable contains multiple conductors, which can be bare metal wires or insulated. Each conductor independently transmits signals or power.

Color coding: The conductors are usually color-coded to help identify different line functions, such as data, clock or power lines.

Flexibility: Although a little stiffer than round cables, ribbon cables are still flexible and can be bent to accommodate different installation needs.

Connectors: Ribbon cables are often used with specialized connectors, such as ZIF (zero insertion force) connectors or IDC (insulation displacement contact) connectors, which can easily align with the cable’s conductors and establish electrical connections.

Ribbon Flat Cable Materials

Conductor Material: Usually copper, because copper has good conductivity and flexibility.

Insulation Material: Polyester, polyimide, polyvinyl chloride or Teflon, etc.

Sheath Material: Polyester, polyurethane, polyvinyl chloride, etc., choose the appropriate material according to the use environment of the cable.

Advantages of Ribbon Flat Cable

The biggest advantage of ribbon cable is that it allows large-scale termination to specially designed insulation displacement connectors (IDC), although ribbon cable can also be terminated by using crimp contacts or solder barrel connections. The IDC termination method allows the conductors of the insulated wire or cable to be contacted through a connection process that forces a sharp blade to penetrate the insulation layer, eliminating the need to strip the insulation layer of the wire before connection. IDC connectors are classified by pin pitch, number of pins, and number of rows.

High-density wiring: Ribbon cable allows high-density signal and power line layout, suitable for occasions where a large number of wires need to be connected.

Space saving: The flat structure makes the cable occupy much less space than traditional round cables, especially suitable for compact electronic equipment.

Easy to route and manage: Due to their flat shape, ribbon cables are easy to route and manage in tight spaces, reducing cluttered harnesses.

Cost-effectiveness: Relatively low production costs, especially in high-volume production.

Quick connections: Ribbon cables are often used with specially designed connectors, such as IDC (insulation displacement contact) connectors, to facilitate fast, reliable connections and disconnections.

Signal integrity: For some designs, such as ribbon cables with polyimide insulation, good signal integrity and high-frequency performance can be provided.

What are flat ribbon cables used for?

Ribbon cable assemblies are commonly used for internal computer components; specifically hard drives, CD drives, and floppy drives. Other uses include connecting moving components such as print heads, consumer electronics and white goods, test and measurement equipment, automatic termination equipment, robotics, and medical devices.

Internal computer connections: Used to connect hard drives, optical drives, motherboards, and other internal components.

Printers and scanners: Inside these devices, ribbon cables are used for signal and data transmission.

Industrial automation: In control panels and inside machines, ribbon cables are used to connect various sensors and actuators.

Medical Devices: Ribbon cables are used to ensure accurate data transmission and signal integrity in precision medical instruments.

Ribbon Cable Considerations:

Signal Interference: Due to the close distance between the conductors, ribbon cables can suffer from crosstalk issues, especially in high-speed data transmission applications.

Length Limitations: To reduce signal attenuation and interference, ribbon cables are often limited in length.

Maintenance and Replacement: Due to its flat and dense structure, ribbon cables can be difficult to repair when damaged and often require replacement in their entirety.

Ribbon cables are the preferred solution for wiring inside many electronic devices due to their unique design.

Ribbon Cable Technical Specifications

Common Ribbon Cable Specifications

Ribbon cables are typically specified by two values ??- the pitch and the number of conductors in the assembly. The pitch or pitch is available in a variety of distances, typically 0.025″, 0.050″, 0.100″, 0.156″, and 1mm pitches, and custom pitches can be available if needed. The number of conductors or paths in the assembly corresponds to the number of positions the connector can accommodate. Connectors are standardized to a certain number of paths, so assemblies are usually limited to 4, 6, 8, 9, 10, 14, 15, 16, 18, 20, 24, 25, 26, 34, 37, 40, 50, 60, 64, and 80 positions. The most common wire used in ribbon cable assemblies is stranded copper wire, ranging in size from 18 AWG to 34 AWG or finer. The insulation material used in ribbon cables is most commonly PVC, but polyester (PET), polyimide (PI), or Teflon (PTFE) materials are also available.

To simplify termination, ribbon cables are often edge marked or color coded. Edge marking or color coding allows for alignment of certain pins on the connector and reduces the risk of reverse connection. Typically, the color of the edge marking on one side of the ribbon cable contrasts with the rest of the cable, and in some cases the color of the edge marking corresponds to the pitch or center spacing of the cable, for example, 0.050-inch pitch cables often use a red edge marking. This marking is used to indicate the conductor that terminates to pin 1 on the connector. For color-coded cables (rainbow ribbon cables, twisted flat cables), the individual conductors are produced in a repeating color pattern. The pattern usually follows the standard resistor color code, which is brown, red, orange, yellow, green, blue, purple, gray, white, and black. If more than ten conductors are required, the color pattern is repeated.

TST CABLES offers ribbon cables with a range of technical specifications that include, but are not limited to, the following:

Specifications: Ribbon flat cables are typically 16 AWG to 34 AWG (other specifications can be customized)

Voltage: Typically low voltage applications

Temperature: -65℃ to +200℃ (other specifications can be customized)

Color sequence: brown, red, orange, yellow, green, blue, gray, white, black, cyclic or as required by the user.

Ribbon flat cables also have their limitations, such as being susceptible to electromagnetic interference (EMI) and crosstalk, especially at high-speed data transmission. In addition, signal attenuation can be a problem over long distances. Therefore, TST CABLES recommends that you consider the specific application requirements and environmental conditions when selecting cables. If you are ready to order ribbon cables, TST cables engineers are ready to help you! You are welcome to email or call us for quotes and free samples.

Also available in:

English