In the power industry, cable trays carry a large number of cables and are responsible for the transmission and distribution of electrical energy. However, once a fire occurs in a cable tray, it may cause serious consequences and pose a huge threat to the safe operation of the power system. Therefore, it is crucial to set up fire-blocking sections (fire sections/fire partitions) on cable trays and select appropriate fire-blocking sections (fire sections/fire partitions) materials. In the power industry, the purpose of implementing fire-blocking sections (fire sections/fire partitions) is to effectively isolate fires, prevent the spread of fire, ensure the safe operation of power facilities, and reduce casualties and property losses. The implementation of fire-blocking sections (fire sections/fire partitions) not only helps to ensure the stability of the power system, but also helps to improve the disaster resistance of power facilities, and provides strong guarantees for the sustainable development of my country’s power industry.

01 Why must the power industry set up fire-blocking sections?

National standards stipulate hard regulations

According to the requirements of GB50217 and GB50872, the following parts should be set up with fireproof sections:

Firewalls or fire-blocking sections should be set up in the following parts of cable trenches, tunnels and overhead bridges:

1) Branches of public cable trenches, tunnels and overhead bridge main channels;

2) Cable trenches and tunnel sections corresponding to multi-section distribution devices;

3) Long-distance cable trenches, tunnels and overhead bridges are separated by about 100m, or in tunnel ventilation sections, and about 200m outside the factory and station;

4) Cable trenches, tunnels and overhead bridges to the entrance of the control room or distribution device, and the factory wall.

The composition of fireproof walls and fire-blocking sections should use fireproof sealing materials suitable for the environmental conditions of cable laying, and should be stable under the possible immersion of water or rodent damage.

The power industry needs to avoid fire risks

The power industry has a high fire risk. With the increase in the number of years of operation, the aging of power equipment is becoming more and more serious, which can easily lead to fire accidents such as equipment short circuit and insulation breakdown. In addition, there may be external fire sources near power facilities, such as welding, etc.; short circuits, grounding and other faults may occur during the operation of power lines, leading to fires.

02 How are the materials and performance of fire-blocking sections stipulated in national standards?

According to relevant national standards, the fire resistance limit of fire-blocking components such as fire-blocking and fire-blocking sections should not be lower than the fire resistance limit of the components of the penetrating parts (such as building walls, floor slabs, etc.), and should not be lower than 1h. Its combustion performance, physical and chemical properties and fire resistance performance should comply with the provisions of the current national standard “Fire-blocking Materials” GB23864, and the test conditions should be consistent with the actual use conditions.

According to the national standard, the materials of fire-blocking sections or “fire-blocking sections/fire-blocking sections” in the power industry should meet the following standards in combination with the actual application of the power industry:

- High temperature stability: Fire-blocking sections or “fire-blocking sections/fire-blocking sections” should maintain stable performance in high temperature environments, and should not be easily burned, deformed or cracked.

- Fire resistance: Fire-blocking sections or “fire-blocking sections/fire-blocking sections” should have good fire resistance and be able to effectively isolate the fire source when a fire occurs.

- Corrosion resistance: Fire-blocking sections or “fire-blocking sections/fire-blocking sections” should have good corrosion resistance to adapt to the special environments of hydropower, wind power, nuclear power and other fields.

- Durability: Fire-blocking sections or “fire-blocking sections/fire-blocking sections” should have a long service life to reduce replacement frequency and operation and maintenance costs.

- Environmental protection performance: Fire-blocking sections or “fire-blocking sections/fire-blocking sections” should meet environmental protection requirements and reduce the impact on the environment.

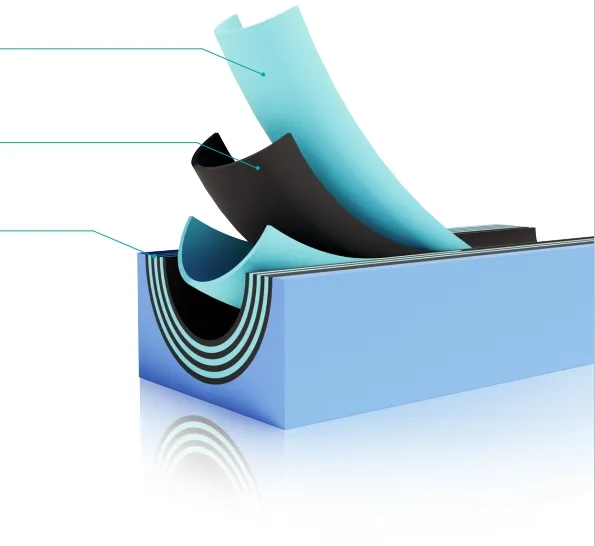

(↓↓↓The following picture is a real shot of the installation of TST CABLES light fire-blocking section)

03 What are the materials for fire-blocking section? There is always one that suits you best!

The most commonly used materials for fire-proof separation of cable trays are fire-proof boards, fire-proof coatings, fire-proof bags, fire-proof mud, and TST CABLES alternative products such as light fire-proof sections. Their advantages and disadvantages are as follows:

(I) Fire-proof coating

Advantages: convenient construction, low cost, and comprehensive protection of cable trays.

Disadvantages: poor fire resistance and durability, requiring regular maintenance and repainting.

(II) Fire-proof bag

Advantages: simple installation, good fire resistance, and can effectively prevent the spread of fire.

Disadvantages: heavy weight, large space occupation, affecting the laying and maintenance of cables, and difficult to dissipate heat.

(Fireproof board (left) Fireproof board (right))

(III) Fireproof board

Advantages: high strength, not easy to damage.

Disadvantages: unstable fire resistance and relatively complex installation.

(IV) Light fire-blocking section

Advantages: easy installation, excellent fire-proof performance, good heat dissipation, and convenient for adding or replacing cables; from the perspective of long-term effects, its performance and maintenance cost advantages are obvious.

Disadvantages: It replaces traditional products and is currently only used in some hydropower, thermal power and other industries, and has low visibility.

In the power industry, the installation of fire-blocking sections (fire-proof sections/fire-proof partitions) on cable trays is an important measure to ensure the safe operation of the power system. Choosing appropriate fire-blocking section materials can effectively improve the fire-proof performance of cable trays and reduce the losses caused by fire. When selecting fire-blocking section materials, it is necessary to fully consider factors such as the type and purpose of the cable tray, fire-proof performance and durability, construction difficulty and cost, and make a comprehensive trade-off to make the best choice.

As an enterprise that focuses on providing light fire-blocking sections and modular cable and pipe penetration sealing system products to users in various industries, TST CABLES will continue to increase its R&D investment in light fire-blocking sections and other fire-proof blocking products to continuously improve the performance and quality of its products. At the same time, TST CABLES will actively cooperate with various industries to provide customized fire protection solutions for different places. Through continuous efforts, TST CABLES will make greater contributions to the fire safety of cable trays in the power industry with more complete light fire-retardant products and better pre-sales, in-sales and after-sales services.

Also available in:

English