What cables are suitable for industrial robot? What are the advantages, application of robot cable? In-depth analysis of the difference between robot cable and ordinary cable.

1. What is a robot cable?

robot cable are a type of flexible cable designed specifically to meet the needs of the robotics industry. They not only improve the performance of robots, but also ensure the safety and efficiency of operations. robot cable play an irreplaceable role in automated production lines, medical equipment, aerospace, military, rescue and other fields.

robot cable, as an indispensable part of modern automation and robotics, play a key role in connecting the brain (control unit) with limbs (actuators, sensors, etc.). They not only need to transmit power, but also be responsible for data communication to ensure that robots can complete various tasks accurately and efficiently. robot cable are used for drag chains or 3D applications. Twistable robot cable meet extremely high industrial stress requirements and have many characteristics such as resistance to hydrolysis and microorganisms, and resistance to ultraviolet rays. TST cables specializes in customizing different types of robot cable, such as American standard UL2586, UL2517, UL2464 cables, PUR robot cable, shielded cables, hybrid cables, fiber optic cables (FOC), motor cables and servo cables.

2. Common types of robot cable:

American standard UL2586, UL2517, UL2464: These are multi-core sheathed wires with the characteristics of torsion resistance, wear resistance, oil resistance, high flexibility, fast signal transmission and long service life.

Wear-resistant and oil-resistant PUR robot cable: Suitable for dynamic bending and torsional movements, designed to withstand up to 10 million torsional movements, with small outer diameter, solid PUR outer sheath, low viscosity surface, and protection against lubricants, acids, alkalis and other chemical media.

Shielded robot cable: In addition to the above characteristics, they also have a shielding layer to prevent electromagnetic interference and ensure clear signal transmission.

3. Performance advantages of robot cable:

Strong durability: robot cable are made of wear-resistant and corrosion-resistant materials, with strong durability and anti-aging ability, and can maintain performance even in high-intensity repetitive movements.

Strong anti-interference: The insulation layer material is well selected and has good anti-interference performance, which can effectively prevent external signals from affecting it and ensure the accuracy and stability of data transmission.

Safe and reliable: The design and manufacturing process is strictly implemented in accordance with international standards to ensure the safety and reliability of the cable during use.

Widely adaptable to different environmental conditions: It can adapt to different environmental conditions, such as high temperature, low temperature, humid or chemically corrosive environments, and ensure normal operation under various harsh conditions.

High flexibility: robot cable have a high bending radius and good flexibility, allowing complex movements in robot joints and arms without being easily damaged.

Excellent signal transmission performance: The internal structure of the cable is optimized to ensure the efficiency of high-speed data and power transmission, which is essential for real-time control and feedback of the robot.

Space saving: The small diameter design helps to wire in a limited space, especially when the internal space of the robot is limited. This is particularly important.

Easy maintenance: Quick connectors and modular design make installation and maintenance easy and fast.

IV. Application of robotic cables

Robotic cables are designed to be flexible, durable, and not easily damaged by repeated bending and twisting. They are commonly used in a variety of robotic and automation equipment applications, including:

1. Robotics

Robotic cables are widely used in robotic arms, grippers, and other robotic components that require flexible cables to transmit signals and power when the robot moves.

2. Automation

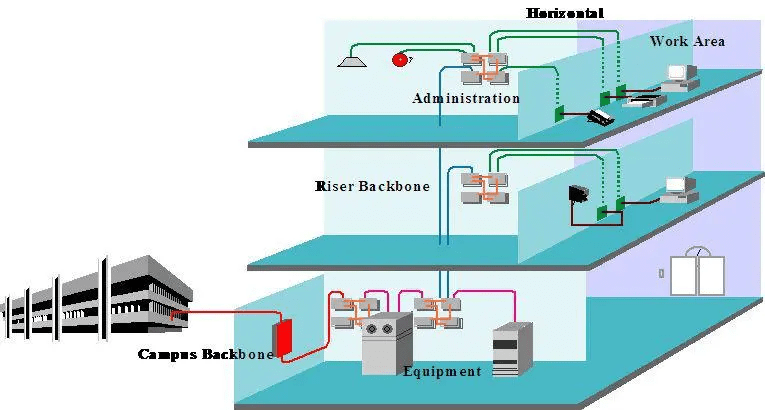

Robotic cables are also used in a variety of automation equipment applications, such as conveyor systems, assembly lines, and industrial machinery. In these applications, the cables need to be able to withstand continuous bending and flexing.

3. Medical equipment

Robotic cables are used in medical equipment, such as MRI machines, surgical robots, and other medical devices that require precise and flexible control.

These cables must be able to transmit signals and power while remaining flexible and lightweight.

4. Aerospace

Robotic cables are used in aerospace applications, such as space exploration and satellite control.

These cables must be able to withstand extreme temperatures, radiation, and other environmental factors when transmitting signals and power to remote devices.

5. Automotive

Robotic cables are used in automotive applications such as automated assembly lines and robotic welding machines.

In these applications, the cables need to be able to withstand high temperatures and resist damage from contact with oil, grease, and other automotive fluids.

6. Other applications

Equipment with torsional and bending motions, machine tools, automated material handling equipment, robots with multiple multi-axis joints, power chains, or machines with moving parts.

Factory and construction projects, multi-axis robots, automated handling equipment, drag chains, or machinery with moving parts. Waterproof and dustproof, resistant to friction and wear.

V. The difference between robot cable and ordinary cables

Robotic cables are essential components in various robotic and automated equipment applications. They provide flexibility, durability, and reliability for the transmission of signals and power.

Due to the particularity of the robot’s operating environment, the design and material selection of robot cable have higher requirements than ordinary cables, which are specifically reflected in the following aspects:

1. High flexibility and durability of robot cable

Bending life: robot cable often need to perform frequent bending movements in a small space. Therefore, they must have extremely high bending life, usually up to millions of times or more, to avoid disconnection or signal interruption due to excessive wear.

Material selection: The outer sheath usually uses high-elastic material, such as polyurethane (TPU), which has good wear resistance and tear resistance and can withstand the friction and pulling generated during the movement of the robot.

2. Shielding and anti-interference ability of robot cable

Electromagnetic compatibility (EMC): robot cable often integrate power lines and signal lines. In order to prevent electromagnetic interference, a shielding layer design is used inside the cable, such as metal braiding or aluminum foil shielding, to ensure the accuracy and stability of data transmission.

Data transmission: With the improvement of the intelligence of robots, high-speed data transmission has become increasingly important. To this end, robot cable use high-performance coaxial cables or optical fibers to achieve high-bandwidth, low-latency data exchange.

3. Environmental adaptability of robot cable

Temperature range: Robots may work in extreme temperatures, from frozen warehouses to high-temperature foundries, so cables must be able to maintain stable performance over a wide temperature range.

Chemical and oil resistance: In some application environments, cables may be exposed to chemicals or lubricants, which requires cable materials to have good chemical resistance to prevent corrosion or degradation.

4. Safety of robot cable

Flame retardant and low smoke and halogen-free: Considering the safety of the robot’s operating environment, robot cable are usually made of flame retardant materials, low smoke and halogen-free, which can slow down the spread of fire and reduce the generation of harmful smoke even in the event of a fire.

Electrical safety: The cable design follows strict electrical safety standards to ensure that it will not cause harm to humans or equipment when operating under high voltage or high frequency conditions.

5. Modularity and customization of robot cable

Connectors: robot cable are usually equipped with quick connectors for easy installation and maintenance, and also support modular connection methods to adapt to different types of robots and application scenarios.

Customized design: In view of the diversity of robot applications, cable suppliers often provide customized services to design cable lengths, types and protection levels according to the specific needs of customers.

6. Intelligentization and integration of robot cable

Intelligent monitoring

Health monitoring system: The new generation of robot cable begins to integrate intelligent monitoring technology, which monitors the status of cables in real time through built-in sensors, including parameters such as temperature, current, and voltage, and timely warns of potential faults, realizes predictive maintenance, and avoids unexpected downtime caused by cable problems.

Integrated solution

Composite cables: In order to simplify robot design and reduce wiring complexity, composite cables with multiple functions have come into being. This type of cable integrates power supply, signal, data transmission and even pneumatic pipelines, which not only reduces the number of cables, but also improves the compactness and reliability of the system.

7. Sustainability and environmental protection of robot cable

Green materials

Recyclable materials: With the improvement of environmental awareness, robot cable manufacturers have begun to explore the use of recyclable or bio-based materials as the outer sheath and insulation layer of cables to reduce the impact on the environment.

Energy efficiency optimization

Energy-saving design: Cable design optimization, such as reducing resistance and reducing signal loss, can effectively reduce the overall energy consumption of robots and improve energy efficiency. This is also an important direction for the development of robot cable in the future.

8. Standardization and interoperability of robot cable

With the widespread application of robot technology around the world, the standardization and interoperability of cables have become particularly important. The International Organization for Standardization (ISO) and other relevant organizations are working hard to develop unified cable interface standards and test specifications to promote compatibility between different brands and types of robots and reduce the difficulty and cost of system integration.

9. Future prospects of robot cable

Material innovation

Nanomaterials and new polymers: In the future, the advancement of nanotechnology and the development of new high-performance polymers will bring revolutionary changes to robot cable, such as lighter, stronger and smarter cables.

Wireless technology

Wireless power supply and data transmission: Although the application of wireless technology in the field of robots is still in its infancy, with the maturity of wireless charging and wireless data transmission technology, future robots may get rid of the constraints of cables and achieve complete wireless freedom of movement.

The development of robot cable is a continuous evolutionary process, which closely follows the advancement of robot technology. robot cable are a vital component of robot systems. Their design and manufacturing need to comprehensively consider mechanical properties, electrical properties, environmental adaptability and safety, etc., to meet the needs of efficient and reliable operation of robots in complex and changing working environments. With the continuous advancement of robotics technology, robotic cables will also develop towards higher performance and smarter direction in the future, becoming an important force to promote automation and intelligent manufacturing.

Work with TST cables to get high-quality robotic cables

As a robotic cable manufacturer, TST cables is the most stable and high-quality partner for your robotic equipment. TST cables focuses on the design, development, production and sales of high-performance robotic cables, integrating cutting-edge technology and exquisite craftsmanship to create an industry benchmark that can withstand tens of millions of twists and resist EMI interference. Small diameter design, space saving, halogen-free, oil-resistant, low smoke halogen-free flame retardant, high and low temperature resistance, fearless of any complex environmental challenges. From precise sensing signals to strong power transmission, every meter of cable carries safety and trust. Work with TST cables to make your robot more agile and intelligent, and jointly create a new era of automation. As one of the world’s leading suppliers of robotic cables, TST cables provides you with a variety of power connection solutions for any application that requires robotic cables. For more information about robotic cables, flexible cables or to place a sample order, please feel free to contact us by email or phone.

Also available in:

English