Fire Resistant

EN45545-2

- Customized Design Production

Small MOQ

Short Lead Time

- Long Time Guarantee

- Home

- /

- Fire Protected Section

Fire Protected Section | Light fire-blocking section

In the fire blocking process, the common fire blocking section is usually built with traditional materials, mainly composed of fireproof board, fireproof bag and fireproof mud. There are disadvantages such as long installation and construction time, heavy weight, poor heat dissipation and short life. In particular, the accumulation of heat from the cable with large heat generation will cause carbonization of the cable insulation layer and outer sheath, which undoubtedly reduces the service life of the cable and increases the fire hazard.

Application for fire protect section:

- The following parts in cable trenches, tunnels and overhead bridges should be set up with fireproof sections;

- The branches of the main channels of public cable trenches, tunnels and overhead bridges;

- The cable trenches and tunnel sections corresponding to multi-section distribution devices;

- Long-distance cable trenches, tunnels and overhead bridges are separated by about 100m, or in the ventilation section of the tunnel, and about 200m outside the plant station

- The entrance of the cable trench, tunnel and overhead bridge to the control room or distribution device, and the factory wall.

New fire-blocking section from TST product introduction

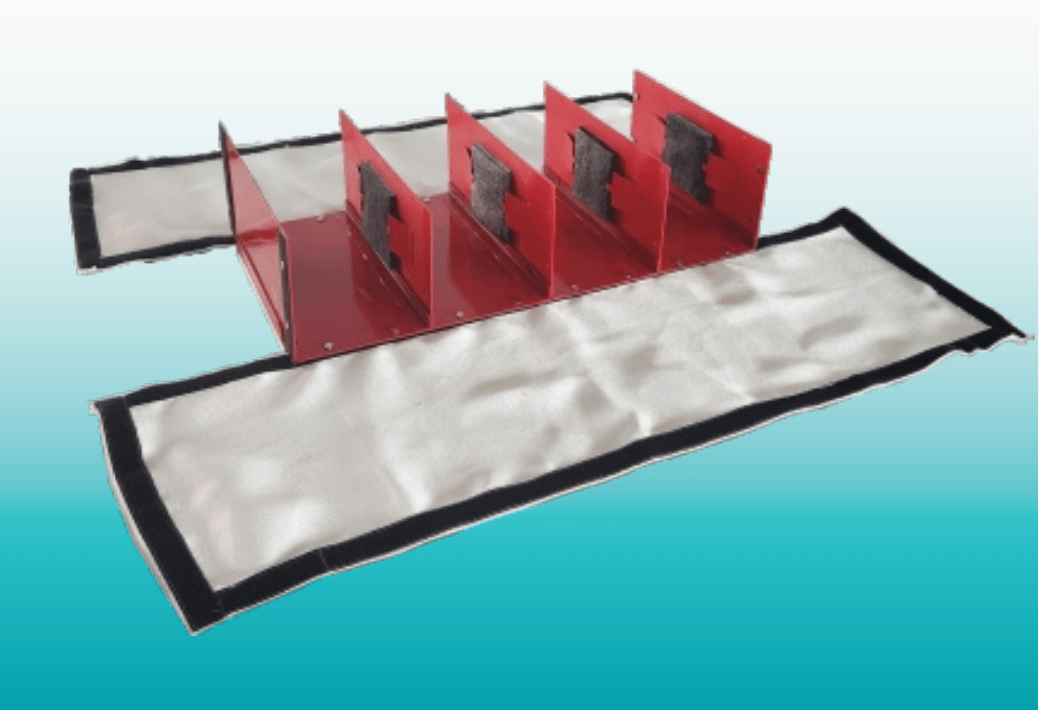

Light fire-blocking section is a fire-proof isolation product made of new intumescent fire-proof material, which is composed of intumescent block, fire-proof cloth, combined metal frame sprayed with fire-proof coating and fire-proof

Flame retardant expansion blocks

Fire retardant fiber cloth

fire retardant coating metal frame

Advantage of light fire protect section

Fire-retardant performance

Equipped with a double fire-blocking system, it significantly improves safety.

- The first layer: fire-resistant fiber cloth, when a fire occurs, the fire-resistant cloth performs the first barrier;

- The second layer: fire-blocking material, the fire-blocking material expands rapidly at high temperatures and fills the cavity, and the material expands to perform the second barrier.

Installation advantages

Lightweight, compact, complete in specifications, and easy to install, it is suitable for applications with or without cable trays installed. Its design allows for easy addition or subtraction of cables without damaging the cable tray structure. A skilled worker can install a set of products in 20 minutes. The product’s upper cover and fireproof fiber cloth are designed to be openable, making it easier to add or subtract cables and more convenient for maintenance.

Product Features

- Lightweight: Standard product, light quality: As a standard product, the light fire-blocking section has corresponding standard specifications for each bridge frame, and is light in weight. The weight of a single set of products is no more than 5Kg, which is very conducive to inventory management and storage, and is also very friendly to the preliminary design.

- Flame retardant and high temperature resistant: It has good flame retardant properties and can prevent the spread of fire under the action of fire source. In high temperature environment, the light fire-blocking section can still maintain stable performance and is not easy to damage.

- Corrosion resistance: It has strong corrosion resistance and is suitable for a variety of environments.

- Environmentally friendly: Environmentally friendly materials are used in the production process, which conforms to the concept of green environmental protection.

- Conducive to heat dissipation: In the light fire-blocking section, the cable will not be completely wrapped by fire-proof mud, fire-proof bag, etc. like in the traditional fire-blocking section. Its state is almost the same as the laying state in the cup holder, which greatly reduces the risk of cable aging caused by heat accumulation in the traditional fire-blocking section.

- Easy to install: The light fire-blocking section is simple to construct and easy to install. Skilled workers can quickly complete the construction of the light fire-blocking section within 5 minutes.

- Long service life: Stable structure and long service life. It can work in harsh environments such as humid working conditions and high temperatures, and its service life is more than 30 years.

Operating environment

- Ambient temperature: -45℃~150℃

- Humidity: 0~100%

- Ozone concentration: ≥100pp

- Protective shell weight: ≥5kg

Metal structural parts

- Use 2mm galvanized sheet

- Surface sprayed with fire retardant paint

Flame retardant expansion material and flame retardant sponge

The flame retardant expansion material, one of the key materials in the fire-blocking section, is in the form of a solid flat plate. It expands when exposed to heat (temperature 160°C), with an expansion ratio of >500%.

After preheating and expansion, its shape changes to a flocculent material and forms a completely incombustible carbon layer. The flocculent material formed by expansion will wrap around the cable surface and fill the gap between the cable and the metal frame to achieve the flame retardant function.

In the early stage of a fire, when the temperature rise does not reach 160°C, the fireproof cloth arranged on both sides of the fire-blocking section can prevent the flame from transferring to the other side (the back of the fire), achieving the function of blocking the initial fire.

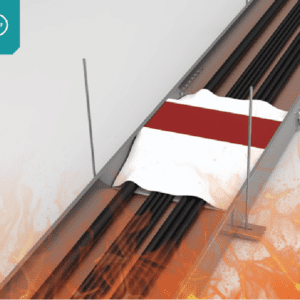

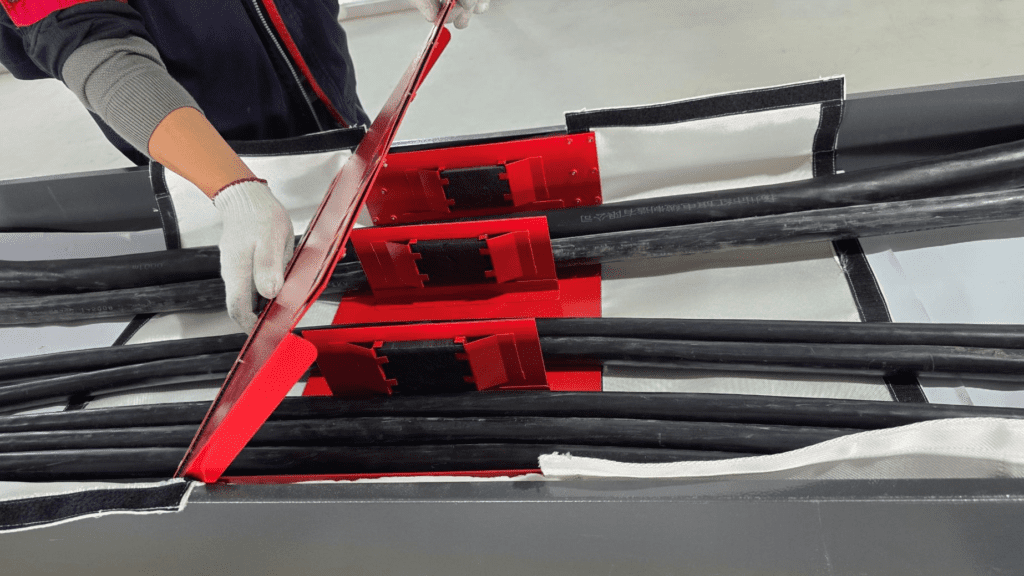

Installation and Schematic Diagram

Lift cable to install bottom plate & fiber fireproof cloth

Sketch of installing the partition plate

Sketch of installing the partition plate

Sketch of installing fireproof cloth on the upper part

Sketch of the installation position of the light intumescent fireproof section

the fireproof section is installed in the cable tray cover, and the identification plate is hung on the outside of the cable tray

Application Case of fire protect section

Firewalls based on lightweight intumescent fireblocks

In the cable tunnel, based on the light expansion fire-blocking section technology, fire-resistant bricks, Class A normally closed fire doors, and light expansion fire-blocking sections are combined with component fire walls. After the cable tray is laid, the light expansion fire-blocking section is installed in the cable tray where the fire wall is required, the cable tray cover is covered, and the wall is built with fire-resistant bricks combined with concrete, the cable tray is built in the wall, and the Class A normally closed fire door is installed on the wall.

Tunnel entrance and exit firewall

It is recommended to install modular firewalls at the entrance and exit of the tunnel, which can prevent a large amount of smoke from spreading into the factory and causing harm to personnel even in the event of a fire. The fire protection level of the modular firewall is 2h (GB23864). The modular sealing components have passed the type test of the National Fireproof Material Supervision and Inspection Center and hold the CCCF certification. They support redundant design, support non-destructive disassembly and assembly, are conducive to standardized cable laying, and have a service life of more than 30 years.

Cable bridge through the wall

It is recommended to set up a modular firewall, which can prevent a large amount of smoke from spreading into the factory and causing harm to personnel even when a fire occurs. The fire protection level of the modular firewall is 2h (GB23864). The modular sealing components have passed the type test of the National Fireproof Material Supervision and Inspection Center and hold the CCCF certification. They support redundant design, support non-destructive disassembly and assembly, are conducive to standardized cable laying, and have a service life of more than 30 years.

Application scenarios and importance of different industries

Industrial plants

The MCT can handle high cable density and reduce the size and weight of the cabinet, saving time and manpower and being prepared for emergency changes.

Data centers and server rooms

In data centers and server rooms, cable trays are used to manage large amounts of data transmission cables, ensuring the stability and security of data transmission.

Subways and tunnelsn und

In underground facilities such as subways and tunnels, cable trays are used to lay power, communication and control cables. These environments have high requirements for cable protection.

Hospitals and laboratories

Hospitals and laboratories require a large number of medical equipment and experimental equipment. Cable trays are used to neatly lay cables while ensuring the safety and reliability of cables.

Outdoor facilities

Such as substations, wind farms, solar power stations, etc., cable trays are used to protect cables from external environmental influences such as ultraviolet rays, rain, dust, etc.

Chemical and petroleum industries

Chemical & petroleum industries, cable trays need to be able to resist corrosive chemicals and high temperatures to ensure long-term and stable operation of cables.

Ships and offshore platforms

Cable trays are used to lay power, control and communication cables in ships and offshore platforms. These environments have extremely high requirements for cable protection.

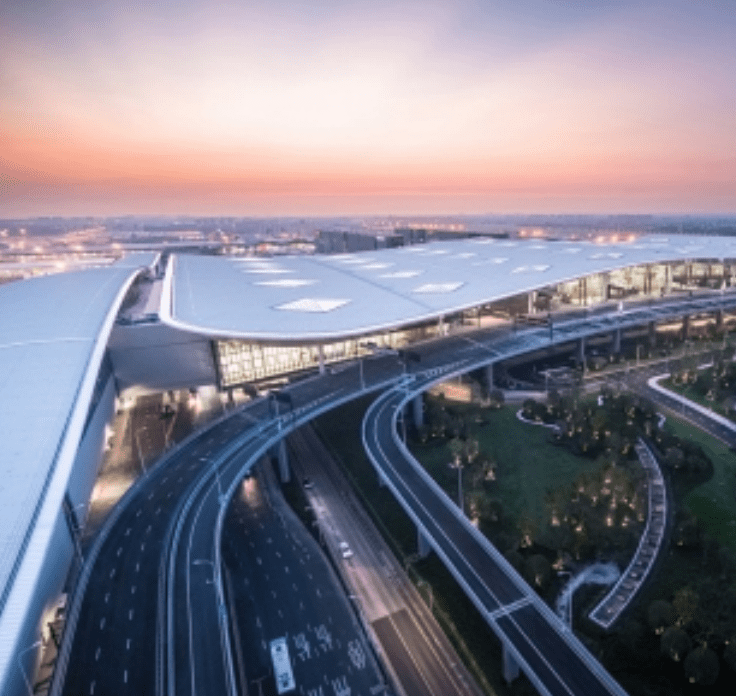

Public facilities

Cable trays are used to manage a large number of power and communication cables in airports, railway stations, stadiums, etc., to ensure the safety of public facilities.

TST Cases in various industries

TST Case & Certification

Related by TST:

Cross linked polyethylene cable (XLPE) deciphers the heat resistance code of rail transit cables

The rapid development of rail transit has put forward higher...

Read MoreHow to choose lszh cable railway cable subway fireproof soft cable

Subway fireproof soft cable is a cable designed to meet...

Read MoreDenmark cable Power Cable Denmark High Voltage Cable Solutions

As a Nordic country, Denmark enjoys a high reputation in...

Read More-200℃-+1200℃ Low smoke halogen free flame retardant PEEK cable Aircraft Cable

PEEK cable has super strong mechanical properties, good toughness and...

Read MoreAlso available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese

Portuguese (Brazil)