Material selection and testing requirements:

- EN50264: This standard deals with cross-linked polyethylene insulation materials. When selecting and testing insulating materials, attention should be paid to their heat resistance, aging resistance, electrical properties, etc. to ensure the stability of the cable in long-term use and under different environmental conditions.

- EN50306: For high voltage cables, special attention should be paid to the dielectric strength and partial discharge characteristics of the insulating materials, etc. These properties directly affect the safety and reliability of cables in high voltage environments.

- EN50382: For silicone-coated glass fiber cloth insulated cables, attention should be paid to the heat resistance and mechanical strength of the silicone coating, as well as the durability and electrical properties of the glass fiber cloth.

Testing and certification standards:

- EN50264: It shall be ensured that the specified insulation resistance test, fire resistance test and electrical performance test are carried out and in strict accordance with the test methods required by the standard.

- EN50306: Partial discharge testing of HV cables is critical but can sometimes be overlooked. Partial discharges are a common precursor to faults in HV cables and therefore must be properly tested and evaluated.

- EN50382: Be aware of the special requirements in the test methods, including testing of electrical characteristics under high temperature conditions, to ensure the reliability of cables in extreme environments.

In-depth analysis ensures that the cable meets the detailed requirements of standards such as EN50264, EN50306 and EN50382:

1、EN 50264 Standard wall cables with special fire performance for rolling stock

Europe Standards railway cables

EN 50264-1、EN 50264-2-1 、EN 50264-2-2 、EN 50264-3-1、EN 50264-3-2;BS 6853、DIN 5510

According to EN 50264-1, EN 50264-2 and EN 50264-3; Complying with BS 6853 and DIN 5510

Applications

These cables are recommended for electric power installation of rated voltages up to and including 3.6/6kV in railway vehicles.

Characteristics

With flexible stranded tinned copper conductor and LSZH insulation and sheath, these cables feature resistance to heat, oil, acid & alkali, cold, abrasion and ozone, excellent mechanical and physical properties, easy to installation, safety and reliability. They are effective in limiting flame propagation and smoke generation under fire conditions, thus eliminating or reducing hazard to people.

Temperature range :-40 ~ 90℃.

Short circuit temperature:200℃(for the duration of 5s)

Mechanical and physical properties

Heat ageing(120℃×240h)

–variation in tensile strength:±30%

— variation in elongation at break:±30%

Oil resistance( Oil immersion:100℃×240h)

— Variation in tensile strength:±30%

— Variation in elongation at break:±40%

Electrical properties

Uo Rated voltages Uo

— Unsheathed cable:0.6KV/1KV;1.8KV/3KV

— Sheathed cable:1.8KV/3KV;3.6KV/6KV

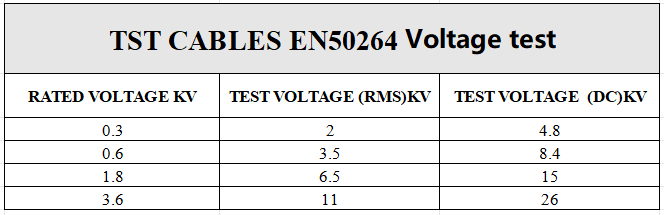

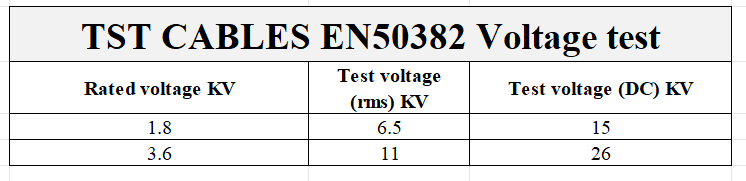

Voltage test

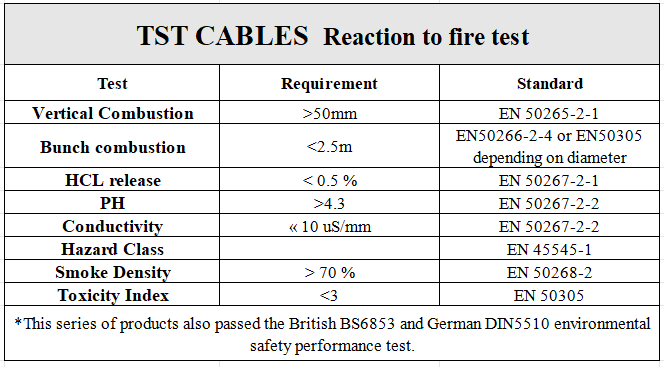

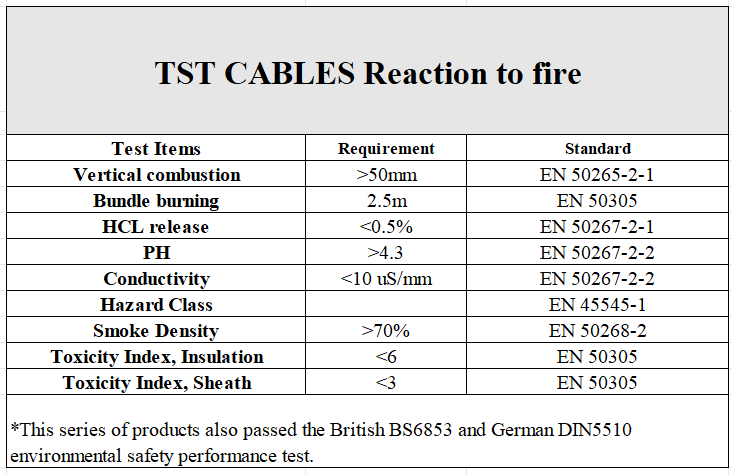

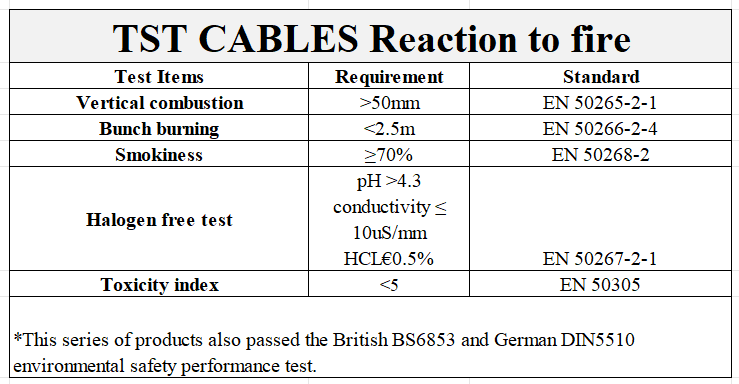

Reaction to fire

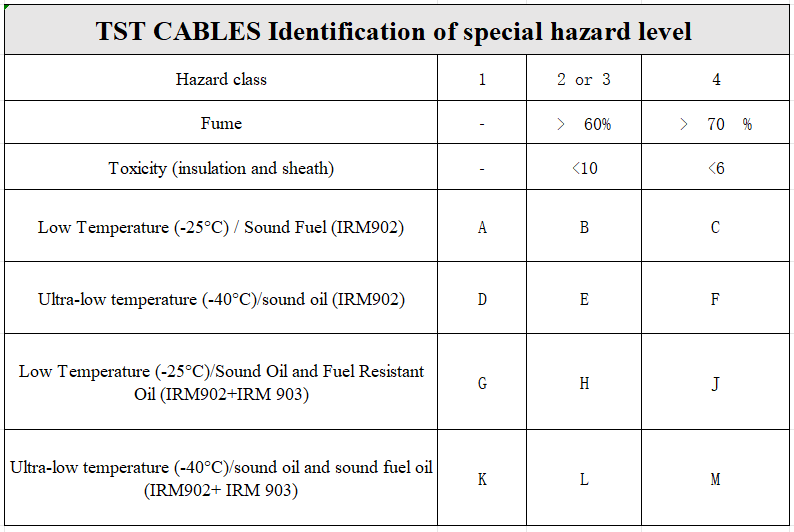

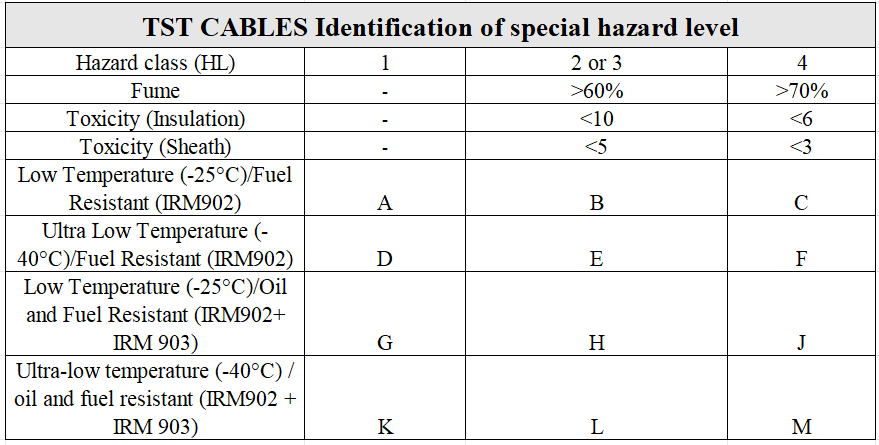

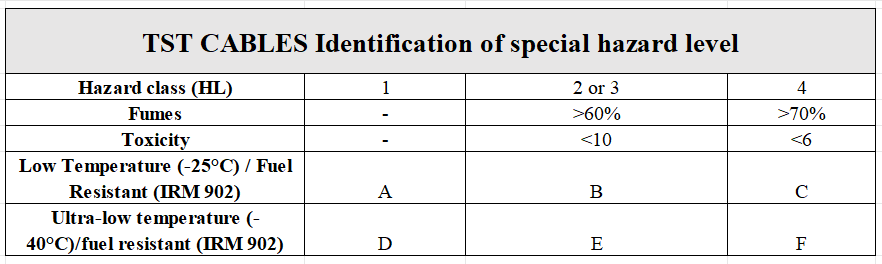

Identification of special hazard level

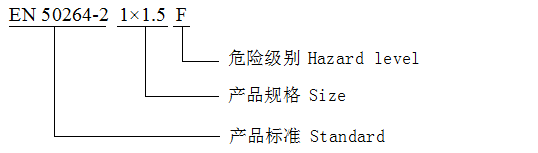

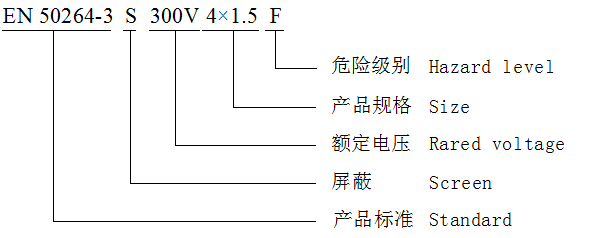

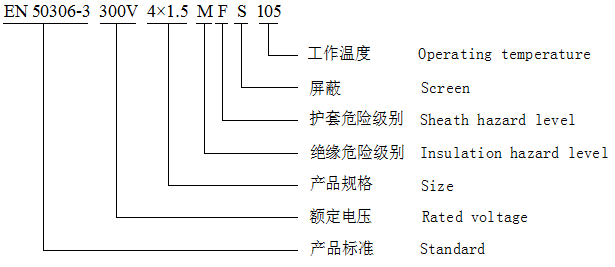

Product designation

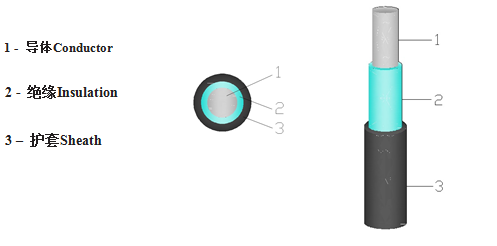

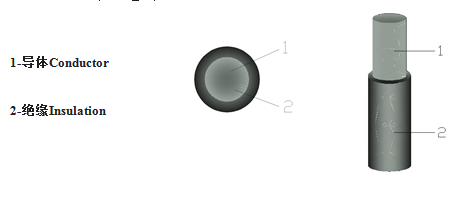

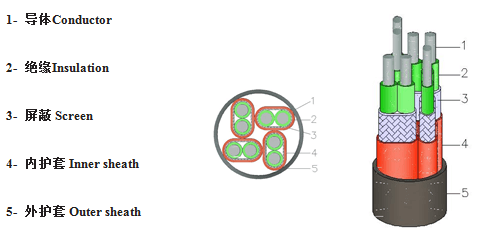

EN 50264 Diagram of cable construction

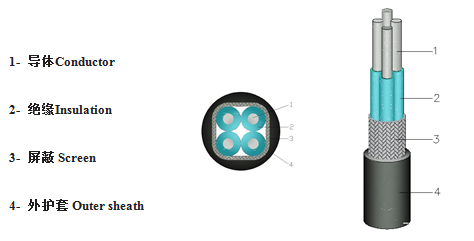

EN 50264-3-2multi-core screened cable

2、EN 50306 Thin wall cables with special fire performance for rolling stock

Europe Standards

According to EN 50306-1, EN 50306-2, EN 50306-3 and EN 50306-4; Complying with BS 6853 and DIN 5510

Applications

These cables are recommended for electric power installation of rated voltages up to and including 300 V in railway vehicles where compactness and light weight are required. They are also suitable for other electric power installation where compactness and light weight are required.

Characteristics

With flexible stranded tinned copper conductor and LSZH insulation and sheath, these cables are made using the thin wall technique and feature small size and light weight, resistance to heat, oil, acid & alkali, cold, abrasion and ozone, excellent mechanical and physical properties, easy to installation, safety and reliability. They are effective in limiting flame propagation and smoke generation under fire conditions thus eliminating or reducing hazard to people

Temperature range:-40 ~ 105℃

Short circuit temperature 160℃( for the duration of 5s )

Electrical properties

Rated voltages:300V( to earth)

Voltage test of complete cable:AC.2000V,5min;DC.4800V,5min

Insulation resistance(MΩ.km):20℃≥600-400;90℃≥0.30-0.20

Mechanical and physical properties

Oil resistance:100±2℃×24h,1.5KV/1min, without breakdown。

Ozone resistance:25±2℃×24h,1.5KV/1min,no cracks。

Bending at low temperature:-40±2℃, no cracks。

Reaction to fire

Identification of special hazard level

Product designation

Diagram of cable construction

EN 50306-3 Multi-core thin wall screened and sheathed cable

EN 50306-4 Multi-core screened and sheathed cable

EN 50306-4 Inner sheath and outer sheath multi-pair cable with individual screen

3、EN 50382 High temperature power cables with special fire performance for rolling stock

Europe Standard

According to EN 50382-1 and EN 50382-2; Complying with BS 6853 and DIN 5510

Applications

These cables are recommended for electric power installation of rated voltages up to and including 3.6/6kV in railway vehicles. They have temperature rating of120℃/150℃.

Characteristics

With flexible stranded tinned copper conductor, HFFR tear resistant silicone rubber insulation and LSZH polyolefine sheath, these cables feature resistance to high temperature, oil, acid & alkali, abrasion and ozone, excellent mechanical and physical properties, easy to installation safety and reliability. They are effective in limiting flame propagation and smoke generation under fire conditions thus eliminating or reducing hazard to people.

Uo Rated voltages Uo:1800V、3600V

Voltage test(50Hz): 6500V、11kV

Temperature range:-25 ~ 150℃

Short circuit temperature:350℃( for the duration of 5s)

Mechanical and physical properties

Tensile strength:≥6MPa

Elongation:≥160%

Ozone resistance:25±2℃×24h, no cracks。

Electrical properties

Dielectric strength:

Rated voltages 1.8KV, min breakdown voltage10KV

Rated voltages 3.6KV, min breakdown voltage 20KV

Leakage current:≤5mA

Voltage test

Reaction to fire

Identification of special hazard level

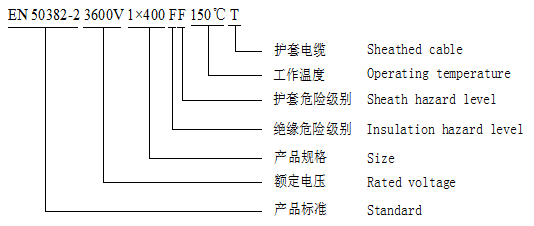

Product designation

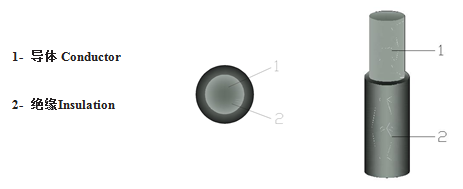

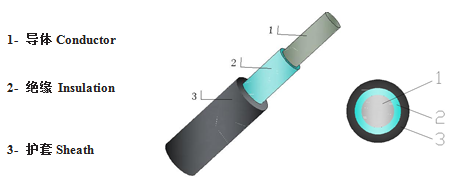

Diagram of cable construction

TST CABLES produces European standard EN50264, EN50306, EN50382 rolling stock cables in various colors and specifications and customized solutions upon request, you can contact us by mail or phone!

Also available in:

English