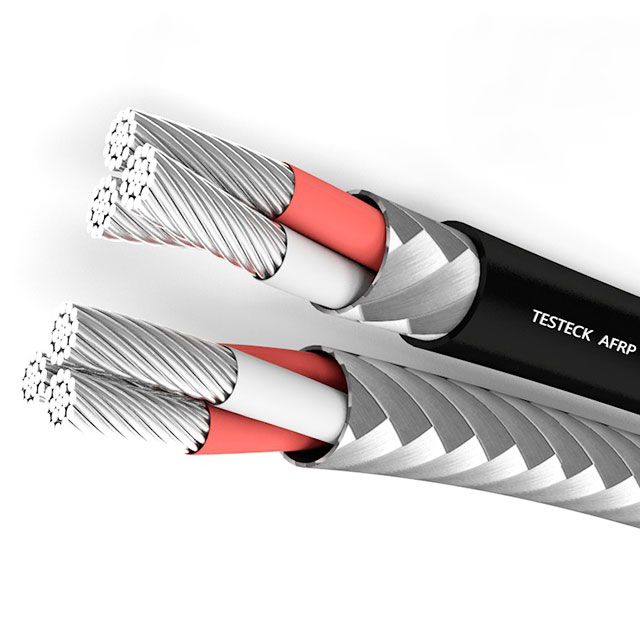

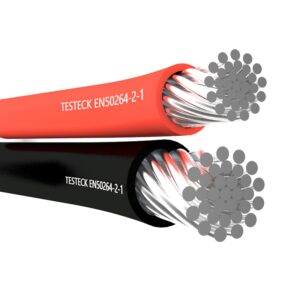

Cables y alambres de alto voltaje de CC de silicona

El alambre y cable de silicona de alto voltaje CC tiene una excelente resistencia a altas y bajas temperaturas, excelente rendimiento de aislamiento eléctrico, excelente estabilidad química, resistencia a alto voltaje, resistencia al envejecimiento y larga vida útil. También es flexible y fácil de instalar.

GET A QUOTE

Aplicación:

«Ampliamente utilizado en encendido de gas, encendido de automóviles, bancos de pruebas de alto voltaje, televisores, hornos microondas, luces de neón, partes internas de alto voltaje de instrumentos y medidores, conexiones de instalación para aparatos electrónicos y otras aplicaciones de alto voltaje».

Característica:

- Tensión nominal: 5kV, 10kV, 15kV, 20kV, 25kV, 30kV, 50kV, 100kV.

- Temperatura de funcionamiento: -60~+200°C.

- Conductor: Cable trenzado de cobre estañado.

- Aislamiento: Caucho de silicona.

- Color: Personalizable.

Estándar en la industria

- Q31/0114000209C026-2017

Parámetro de selección

| Nivel de voltaje | Sección nominal del conductor | Estructura de conductores | Grosor del aislamiento | Diámetro exterior medio | Resistencia CC máxima del conductor a 20 ℃ |

| KV | mm2 | Número de raíces/diámetro del alambre único | mm | mm | Ω/km |

| 5 | 0.2 | 7/0.20 | 1 | 2.6 | 95 |

| 0.35 | 19/0.16 | 1 | 2.8 | 53.1 | |

| 0.5 | 16/0.20 | 1 | 3 | 10.1 | |

| 0.75 | 24/0.20 | 1.2 | 3.6 | 26.7 | |

| 1 | 32/0.20 | 1.3 | 4 | 20 | |

| 1.5 | 30/0.25 | 1.5 | 4.6 | 13.7 | |

| 2.5 | 49/0.25 | 1.6 | 5.4 | 8.21 | |

| 10 | 0.2 | 7/0.20 | 1.3 | 3.2 | 95 |

| 0.35 | 19/0.16 | 1.3 | 3.4 | 53.1 | |

| 0.5 | 16/0.20 | 1.3 | 3.6 | 10.1 | |

| 0.75 | 24/0.20 | 1.5 | 4.2 | 26.7 | |

| 1 | 32/0.20 | 1.5 | 4.4 | 20 | |

| 1.5 | 30/0.25 | 1.8 | 5.2 | 13.7 | |

| 2.5 | 49/0.25 | 1.8 | 5.8 | 8.21 | |

| 4 | 56/0.30 | 2 | 6.8 | 5.09 | |

| 6 | 84/0.30 | 2 | 7.6 | 3.39 | |

| 15 | 0.2 | 7/0.20 | 1.7 | 4 | 95 |

| 0.35 | 19/0.16 | 1.7 | 4.2 | 53.1 | |

| 0.5 | 16/0.20 | 1.7 | 4.4 | 40.1 | |

| 0.75 | 24/0.20 | 2 | 5.2 | 26.7 | |

| 1 | 32/0.20 | 2 | 5.3 | 20 | |

| 1.5 | 30/0.25 | 2.2 | 6 | 13.7 | |

| 2.5 | 49/0.25 | 2.2 | 6.6 | 8.21 | |

| 4 | 56/0.30 | 2.4 | 7.6 | 5.09 | |

| 6 | 84/0.30 | 2.4 | 8.4 | 3.39 | |

| 20 | 0.2 | 7/0.20 | 1.8 | 4.2 | 95 |

| 0.35 | 19/0.16 | 1.8 | 4.4 | 53.1 | |

| 0.5 | 16/0.20 | 1.8 | 4.6 | 40.1 | |

| 0.75 | 24/0.20 | 2.2 | 5.6 | 26.7 | |

| 1 | 32/0.20 | 2.2 | 5.8 | 20 | |

| 1.5 | 30/0.25 | 2.4 | 6.4 | 13.7 | |

| 2.5 | 49/0.25 | 2.4 | 7 | 8.21 | |

| 4 | 56/0.30 | 2.6 | 8 | 5.09 | |

| 6 | 84/0.30 | 2.6 | 8.8 | 3.39 | |

| 25 | 0.2 | 7/0.20 | 2.5 | 5.6 | 95 |

| 0.35 | 19/0.16 | 2.5 | 5.8 | 53.1 | |

| 0.5 | 16/0.20 | 2.5 | 6 | 40.1 | |

| 0.75 | 24/0.20 | 2.7 | 6.6 | 26.7 | |

| 1 | 32/0.20 | 2.7 | 6.8 | 20 | |

| 1.5 | 30/0.25 | 2.9 | 7.5 | 13.7 | |

| 2.5 | 49/0.25 | 2.9 | 8 | 8.21 | |

| 4 | 56/0.30 | 3.1 | 9 | 5.09 | |

| 6 | 84/0.30 | 3.1 | 9.8 | 3.39 | |

| 30 | 0.2 | 7/0.20 | 3 | 6.6 | 95 |

| 0.35 | 19/0.16 | 3 | 6.8 | 53.1 | |

| 0.5 | 16/0.20 | 3 | 7 | 40.1 | |

| 0.75 | 24/0.20 | 3.4 | 8 | 26.7 | |

| 1 | 32/0.20 | 3.4 | 8.2 | 20 | |

| 1.5 | 30/0.25 | 3.6 | 9 | 13.7 | |

| 2.5 | 49/0.25 | 3.6 | 9.4 | 8.21 | |

| 4 | 56/0.30 | 3.8 | 10.5 | 5.09 | |

| 6 | 84/0.30 | 3.8 | 11.2 | 3.39 | |

| 50 | 0.2 | 7/0.20 | 7 | 14.6 | 95 |

| 0.35 | 19/0.16 | 7 | 14.8 | 53.1 | |

| 0.5 | 16/0.20 | 7 | 15 | 40.1 | |

| 0.75 | 24/0.20 | 7.2 | 15.6 | 26.7 | |

| 1 | 32/0.20 | 7.2 | 15.8 | 20 | |

| 1.5 | 30/0.25 | 7.5 | 16.6 | 13.7 | |

| 2.5 | 49/0.25 | 7.5 | 17.2 | 8.21 | |

| 4 | 56/0.30 | 8 | 19 | 5.09 | |

| 6 | 84/0.30 | 8 | 20 | 3.39 | |

| 100 | 1 | 32/0.30 | 12 | 25 | 20 |

| 1.5 | 30/0.25 | 13 | 27.8 | 13.7 | |

| 2.5 | 49/0.25 | 13 | 28.5 | 8.21 | |

| CONSEJOS: Según el acuerdo técnico entre las dos partes, se pueden producir productos con otras especificaciones. | |||||

Also available in:

Árabe

Inglés

Alemán

Indonesio

Japonés

Ruso

Español

Tailandés

Vietnamita