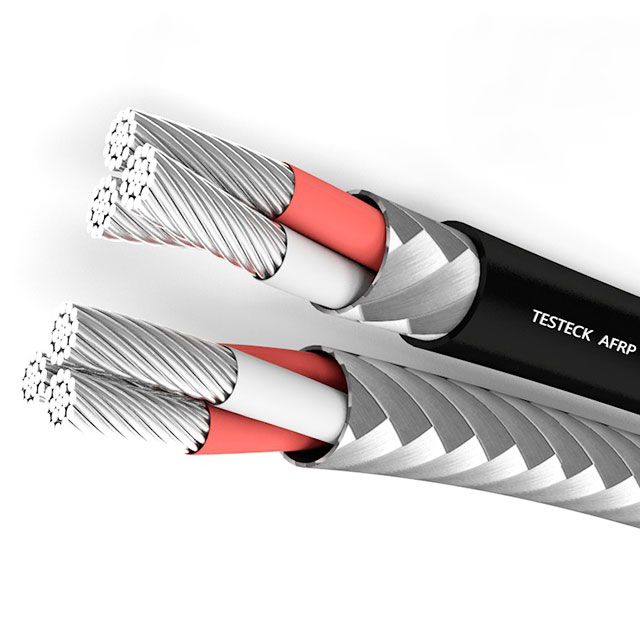

PTFE/Teflon-Kabel. Hitzebeständiger, ummantelter Draht und Kabel aus Silikon

PTFE/Teflon-Kabel zeichnen sich durch eine hervorragende Hochtemperatur- und Niedertemperaturbeständigkeit, eine hervorragende elektrische Isolationsleistung, eine hervorragende chemische Stabilität, eine hohe Spannungsbeständigkeit, Alterungsbeständigkeit und eine lange Lebensdauer aus. Außerdem ist es flexibel und einfach zu installieren.

GET A QUOTE

Anwendung:

„Geeignet für den Einsatz in verschiedenen mobilen Maschinen, Stahl, Luftfahrt, Kraftwerken, Petrochemie und anderen Hochtemperaturumgebungen mit Nennwechselspannungen von 450/750 V und darunter.“

Charakteristisch:

- Nennspannung: 300/500 V

- Betriebstemperatur: -60~+200℃

- Leiter: Blanker Kupferleiter oder verzinnter Kupferlitzendraht

- Isolierung: FEP (Fluoriertes Ethylenpropylen)

- Mantel: Silikonkautschuk

- Farbe: Anpassbar

Industriestandard

- Q/IRMV3 -2008

Auswahlparameter

| Anzahl der Adern×Abschnitt (mm2) | Leiterstruktur (mm) | Isolationsdicke (mm) | Außendurchmesser der Isolierung (mm) | Manteldicke (mm) | Durchschnittlicher Außendurchmesser (mm) | Gleichstromwiderstand des Leiters bei 20°C (Ω/km) |

| 2 × 0.08 | 7/0.12 | 0.2 | 0.78 | 0.8 | 2.4 | 245 |

| 3 × 0.08 | 7/0.12 | 0.2 | 0.78 | 1 | 3.8 | 245 |

| 4 × 0.08 | 7/0.12 | 0.2 | 0.78 | 1 | 4 | 245 |

| 5 × 0.08 | 7/0.12 | 0.2 | 0.78 | 1.2 | 4.5 | 245 |

| 6 × 0.08 | 7/0.12 | 0.2 | 0.78 | 1.4 | 5.2 | 245 |

| 7 × 0.08 | 7/0.12 | 0.2 | 0.78 | 1.4 | 5.2 | 245 |

| 2 × 0.12 | 7/0.15 | 0.25 | 0.95 | 0.9 | 3.8 | 163 |

| 3 × 0.12 | 7/0.15 | 0.25 | 0.95 | 1 | 4.1 | 163 |

| 4 × 0.12 | 7/0.15 | 0.25 | 0.95 | 1 | 4.3 | 163 |

| 5 × 0.12 | 7/0.15 | 0.25 | 0.95 | 1.2 | 5 | 163 |

| 6 × 0.12 | 7/0.15 | 0.25 | 0.95 | 1.2 | 5.2 | 163 |

| 7 × 0.12 | 7/0.15 | 0.25 | 0.95 | 1.2 | 5.2 | 163 |

| 8 × 0.2 | 7/0.15 | 0.25 | 0.95 | 1.2 | 5.6 | 163 |

| 10 × 0.12 | 7/0.15 | 0.25 | 0.95 | 1.3 | 6.4 | 163 |

| 12 × 0.12 | 7/0.15 | 0.25 | 0.95 | 1.3 | 6.8 | 163 |

| 19 × 0.12 | 7/0.15 | 0.25 | 0.95 | 1.3 | 7.4 | 163 |

| 2 × 0.2 | 7/.20 | 0.25 | 1.1 | 1.2 | 4.6 | 90.4 |

| 3 × 0.2 | 19/0.12 | 0.25 | 1.1 | 1.3 | 5 | 90.4 |

| 3 × 0.2 | 7/0.20 | 0.25 | 1.1 | 1.5 | 5.5 | 90.4 |

| 4 × 0.2 | 7/0.20 | 0.25 | 1.1 | 1.2 | 5 | 90.4 |

| 5 × 0.2 | 7/0.20 | 0.25 | 1.1 | 1.2 | 5.4 | 90.4 |

| 5 × 0.2 | 19/0.12 | 0.25 | 1.1 | 1.5 | 6 | 90.4 |

| 6 × 0.2 | 7/0.20 | 0.25 | 1.1 | 1.2 | 5.8 | 90.4 |

| 7 × 0.2 | 7/0.20 | 0.25 | 1.1 | 1.2 | 5.8 | 90.4 |

| 8 × 0.2 | 7/0.20 | 0.25 | 1.1 | 1.2 | 6 | 90.4 |

| 10 × 0.2 | 7/0.20 | 0.25 | 1.1 | 1.2 | 6.8 | 90.4 |

| 12 × 0.2 | 7/0.20 | 0.25 | 1.1 | 1.4 | 7.5 | 90.4 |

| 19 × 0.2 | 7/0.20 | 0.25 | 1.1 | 1.4 | 8.2 | 90.4 |

| 2 × 0.35 | 19/0.16 | 0.25 | 1.3 | 0.8 | 4.2 | 53.1 |

| 3 × 0.35 | 19/0.16 | 0.25 | 1.3 | 1.1 | 5 | 53.1 |

| 4 × 0.35 | 19/0.16 | 0.25 | 1.3 | 1.2 | 5.5 | 53.1 |

| 5 × 0.35 | 19/0.16 | 0.25 | 1.3 | 1.3 | 6.2 | 53.1 |

| 6 × 0.35 | 19/0.16 | 0.25 | 1.3 | 1.4 | 6.8 | 53.1 |

| 7 × 0.35 | 19/0.16 | 0.25 | 1.3 | 1.4 | 6.8 | 53.1 |

| 8 × 0.35 | 19/0.16 | 0.25 | 1.3 | 1.4 | 7 | 53.1 |

| 9 × 0.35 | 19/0.16 | 0.25 | 1.3 | 1.5 | 7.8 | 53.1 |

| 10 × 0.35 | 19/0.16 | 0.25 | 1.3 | 1.5 | 8.2 | 53.1 |

| 12 × 0.35 | 19/0.16 | 0.25 | 1.3 | 1.5 | 8.4 | 53.1 |

| 14 × 0.35 | 19/0.16 | 0.25 | 1.3 | 1.5 | 8.8 | 53.1 |

| 19 × 0.35 | 19/0.16 | 0.25 | 1.3 | 1.5 | 9.5 | 53.1 |

| 2 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.2 | 5.2 | 40.1 |

| 3 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.2 | 5.5 | 40.1 |

| 4 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.4 | 6.2 | 40.1 |

| 5 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.4 | 6.6 | 40.1 |

| 6 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.4 | 7 | 40.1 |

| 7 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.4 | 7 | 40.1 |

| 8 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.4 | 7.4 | 40.1 |

| 9 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.4 | 8 | 40.1 |

| 10 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.5 | 8.6 | 40.1 |

| 12 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.5 | 8.8 | 40.1 |

| 14 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.5 | 9.2 | 40.1 |

| 17 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.6 | 10.2 | 40.1 |

| 19 × 0.5 | 19/0.18 | 0.25 | 1.4 | 1.6 | 10.2 | 40.1 |

| 2 × 0.75 | 19/0.23 | 0.25 | 1.7 | 1.1 | 5.6 | 24.6 |

| 3 × 0.75 | 19/0.23 | 0.25 | 1.7 | 1.4 | 6.5 | 24.6 |

| 4 × 0.75 | 19/0.23 | 0.25 | 1.7 | 1.5 | 7.2 | 24.6 |

| 5 × 0.75 | 19/0.23 | 0.25 | 1.7 | 1.5 | 7.6 | 24.6 |

| 6 × 0.75 | 19/0.23 | 0.25 | 1.7 | 1.5 | 8.1 | 24.6 |

| 7 × 0.75 | 19/0.23 | 0.25 | 1.7 | 1.5 | 8.1 | 24.6 |

| 8 × 0.75 | 19/0.23 | 0.25 | 1.7 | 1.5 | 8.6 | 24.6 |

| 10 × 0.75 | 19/0.23 | 0.25 | 1.7 | 1.6 | 10 | 24.6 |

| 12 × 0.75 | 19/0.23 | 0.25 | 1.7 | 1.6 | 10.3 | 24.6 |

| 14 × 0.75 | 19/0.23 | 0.25 | 1.7 | 1.6 | 10.8 | 24.6 |

| 19 × 0.75 | 19/0.23 | 0.25 | 1.7 | 1.8 | 12.1 | 24.6 |

| 2 × 1 | 19/0.26 | 0.25 | 1.8 | 1.2 | 6 | 20.4 |

| 3 × 1 | 19/0.26 | 0.25 | 1.8 | 1.2 | 6.2 | 20.4 |

| 4 × 1 | 19/0.26 | 0.25 | 1.8 | 1.2 | 6.8 | 20.4 |

| 5 × 1 | 19/0.26 | 0.25 | 1.8 | 1.4 | 7.6 | 20.4 |

| 6 × 1 | 19/0.26 | 0.25 | 1.8 | 1.4 | 8.2 | 20.4 |

| 7 × 1 | 19/0.26 | 0.25 | 1.8 | 1.4 | 8.2 | 20.4 |

| 8 × 1 | 19/0.26 | 0.25 | 1.8 | 1.4 | 8.6 | 20.4 |

| 10 × 1 | 19/0.26 | 0.25 | 1.8 | 1.6 | 10.4 | 20.4 |

| 12 × 1 | 19/0.26 | 0.25 | 1.8 | 1.6 | 10.8 | 20.4 |

| 14 × 1 | 19/0.26 | 0.25 | 1.8 | 1.6 | 11.2 | 20.4 |

| 19 × 1 | 19/0.26 | 0.25 | 1.8 | 1.8 | 12.6 | 20.4 |

| 2 × 1.5 | 19/0.32 | 0.3 | 2.25 | 1 | 6.5 | 12.7 |

| 3 × 1.5 | 19/0.32 | 0.3 | 2.25 | 1.4 | 7.6 | 12.7 |

| 4 × 1.5 | 19/0.32 | 0.3 | 2.25 | 1.4 | 8.2 | 12.7 |

| 5 × 1.5 | 19/0.32 | 0.3 | 2.25 | 1.5 | 9.1 | 12.7 |

| 6 × 1.5 | 19/0.32 | 0.3 | 2.25 | 1.5 | 9.8 | 12.7 |

| 7 × 1.5 | 19/0.32 | 0.3 | 2.25 | 1.5 | 9.8 | 12.7 |

| 8 × 1.5 | 19/0.32 | 0.3 | 2.25 | 1.6 | 10.6 | 12.7 |

| 10 × 1.5 | 19/0.32 | 0.3 | 2.25 | 1.6 | 12.2 | 12.7 |

| 12 × 1.5 | 19/0.32 | 0.3 | 2.25 | 1.8 | 13 | 12.7 |

| 14 × 1.5 | 19/0.32 | 0.3 | 2.25 | 1.8 | 13.6 | 12.7 |

| 19 × 1.5 | 19/0.32 | 0.3 | 2.25 | 1.8 | 14.9 | 12.7 |

| 2 × 2.5 | 19/0.41 | 0.4 | 2.8 | 1.4 | 8.4 | 7.43 |

| 3 × 2.5 | 19/0.41 | 0.4 | 2.8 | 1.4 | 8.8 | 7.43 |

| 4 × 2.5 | 19/0.41 | 0.4 | 2.8 | 1.5 | 9.8 | 7.43 |

| 5 × 2.5 | 19/0.41 | 0.4 | 2.8 | 1.5 | 10.6 | 7.43 |

| 6 × 2.5 | 19/0.41 | 0.4 | 2.8 | 1.6 | 11.6 | 7.43 |

| 7 × 2.5 | 19/0.41 | 0.4 | 2.8 | 1.6 | 11.6 | 7.43 |

| 8 × 2.5 | 19/0.41 | 0.4 | 2.8 | 1.8 | 12.8 | 7.43 |

| 10 × 2.5 | 19/0.41 | 0.4 | 2.8 | 1.8 | 14.8 | 7.43 |

| 12 × 2.5 | 19/0.41 | 0.4 | 2.8 | 1.8 | 15.2 | 7.43 |

| 14 × 2.5 | 19/0.41 | 0.4 | 2.8 | 2 | 16.4 | 7.43 |

| 19 × 2.5 | 19/0.41 | 0.4 | 2.8 | 2 | 18 | 7.43 |

| 2 × 4 | 37/0.37 | 0.4 | 3.4 | 1.4 | 9.6 | 4.81 |

| 3 × 4 | 37/0.37 | 0.4 | 3.4 | 1.4 | 10.2 | 4.81 |

| 4 × 4 | 37/0.37 | 0.4 | 3.4 | 1.6 | 11.4 | 4.81 |

| 5 × 4 | 37/0.37 | 0.4 | 3.4 | 1.6 | 12.4 | 4.81 |

| 6 × 4 | 37/0.37 | 0.4 | 3.4 | 1.8 | 13.8 | 4.81 |

| 7 × 4 | 37/0.37 | 0.4 | 3.4 | 1.8 | 13.8 | 4.81 |

| 2 × 0.35+2 × 0.14 | 19/0.16 | 7/0.16 | 1.3 | 0.95 | 1.5 | 6 |

| 2 × 0.35+4 × 0.14 | 19/0.16 | 7/0.16 | 1.3 | 0.95 | 1.4 | 6.3 |

| 3 × 0.2+2 × 0.4 | 26/0.10 | 52/0.10 | 1.1 | 1.35 | 0.9 | 5.2 |

| 3 × 0.35+2 × 0.5 | 19/0.16 | 19/0.18 | 1.3 | 1.4 | 1.2 | 6 |

| 3 × 0.75+1 × 0.5 | 19/0.23 | 19/0.18 | 1.7 | 1.4 | 1.1 | 6.3 |

| 4 × 0.75+2 × 0.2 | 19/0.23 | 7/0.20 | 1.7 | 1 | 2 | 8.8 |

| 3 × 0.35+4 × 0.1 | 19/0.16 | 7/0.15 | 1.3 | , , 0.95 | 1.3 | 6.3 |

| 2 × 0.35+6 × 0.14 | 19/0.16 | 7/0.16 | 1.3 | 0.95 | 1.3 | 6.3 |

| 6 × 0.2+2 × 0.3 | 19/0.12 | 19/0.16 | 1.1 | 1.3 | 1.2 | 6 |

Also available in:

Arabisch

Englisch

Deutsch

Indonesisch

Japanisch

Russisch

Spanisch

Thai

Vietnamesisch

WHY CHOOSE TST

19 quality tests before cable shipment

R&D personnel account for 42% of the company’s headcount

Support all kinds of customization, free sampling

10,000 ㎡ factory, annual production capacity of 2,000,000 meters