- Home

- /

- Daily News

DAILY NEWS

TST CABLES High Temperature Cable Technological Innovation Reaching the World

TST CABLES is mainly engaged in the systematic research and development, design, manufacturing, marketing and service of high-end cable products such as high-temperature cables, PEEK cables, PI cables, rail transit cables, ship cables, watertight cables, overhead wires, power cables, wires and cables for electrical equipment, special cables, etc. The products are widely used in aviation, construction, logistics, medical, smart power, smart transportation, smart energy and smart construction, etc. The company has more than 1,600 sets of advanced production equipment and testing equipment at home and abroad, and has formed a cross-linked polyethylene insulated power cable with a maximum voltage level of 500kV and an overhead wire with a maximum voltage level of 1100kV. The production and sales have been at

TST CABLES promotes innovation in LSOH cables for global high temperature cables(MV)

TST CABLES is a sub-brand of Shenzhen TST CABLES Technology Co., Ltd. With “professionalism, innovation, quality, and safety” as its core values, it is committed to providing safe and stable cable supply to China and the world. TST was first established in two thousand three and is located in Shenzhen High-tech Industrial Park. The company has a total number of two hundred people and has more than twenty years of experience in cable R&D and production. It is a company that provides overall solutions and products for cables, sensing, transmission, and electromagnetic compatibility. national high-tech enterprise. So far, TST CABLES has served customers in more than ten industries and categories, including rail transit, communications, electricity, ships, oil and gas, construction,

Inheritance and Innovation Review of TST CABLES New Year Tea Party(MV)

TST CABLES’s employee cafeteria is newly decorated, hung with red lanterns and ribbons, and exquisite refreshments are placed on the table. On this cold winter day, we gather here – the place where we struggle. Today, it is not for the busy work, but to celebrate the efforts and achievements of the past year and welcome the new year full of hope. Leaders and employees greet each other and laugh and communicate. This is where TST CABLES struggles together; at this moment, it turns into a warm harbor. Behind every familiar face, there are countless stories and sweat. We are not only colleagues, but also a family that trusts and supports each other. Management members and ordinary employees set up

TST CABLES Technology and Jinshajiang No. 1 Power Station held a discussion on wireless measurement technology for hydropower generator sets

On December 12, 2024, TST CABLES Technology’s wireless temperature measurement experts led a team to the Jinsha River Basin No. 1 Power Station project to conduct a discussion on wireless measurement technology for hydropower generator sets. The exchange focused on new measurement methods, mainly the feasibility, advantages and innovation and upgrading of wireless measurement technology on hydropower station equipment, and jointly explored new paths for the application and development of wireless measurement technology in the hydropower industry. Note: (Due to customer privacy requirements, all are marked with “a certain power station”, “***” and “the power station”) As a well-known company in the field of large-scale hydropower temperature measurement, TST CABLES Technology has always focused on the research and development and application of

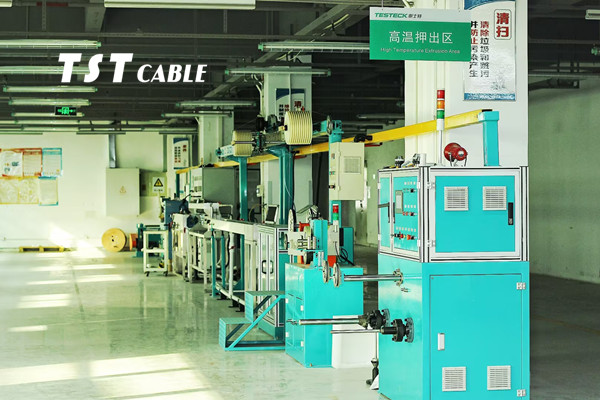

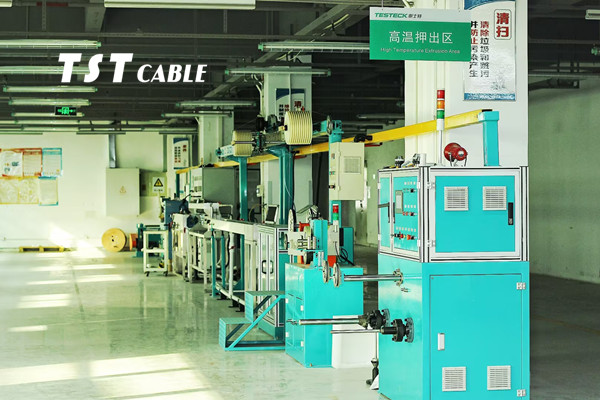

TST CABLES’ new PEEK cable TPI cable production line is online

TST CABLES production workshop, Building 3, Security Technology Industrial Park, Guangming District, Shenzhen, October 30, 2024-TST CABLES announced that its newly introduced PEEK cable/TPI cable production line and equipment will be officially put into operation. The production line is designed for the production of high-performance PEEK round wire and TPI round wire, marking another milestone for the company in the field of high-end cable manufacturing. Highlights of PEEK cable TPI cable production line equipmentThe new equipment is highly intelligent and automated, which not only improves production efficiency, but also greatly improves product quality. According to the equipment operator, the main function of the production line is to produce special cables made of PEEK and TPI materials. Through the design of

Application case of modular sealing “weapon” in cabinet system of Jinsha River Basin power station

Under the background of “dual carbon”, my country’s energy transformation is accelerating. As an important part of clean energy, hydropower plays an irreplaceable and important role in the construction of clean, low-carbon, safe, efficient, flexible and intelligent new energy system and new power system. As the core component of the hydropower station, the cabinet system is responsible for the distribution, protection and control of electric energy to ensure the normal operation of the power system. However, cabinets face many challenges in hydropower stations, including insufficient sealing performance, extreme environmental conditions, and complex internal wiring. These problems can cause equipment failure and distortion of monitoring data, affecting the working performance of the equipment and the power generation efficiency of the hydropower

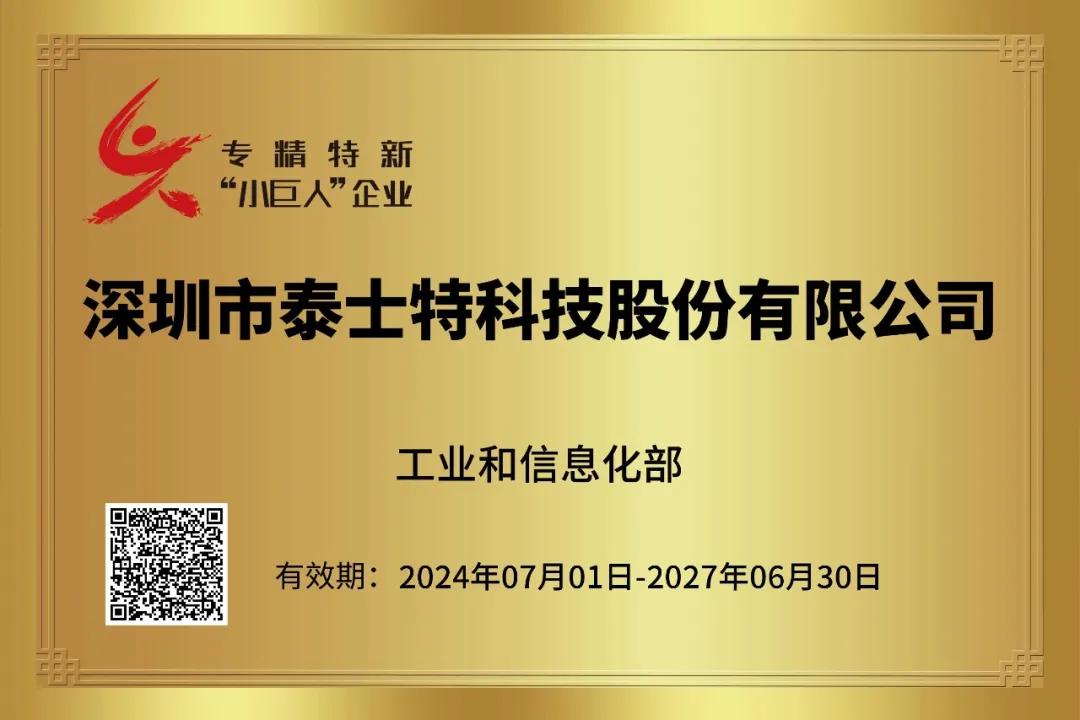

Good news! TST CABLES won the honorary title of national-level specialized and new “little giant” enterprise

Good news! TST CABLES won the honorary title of national-level specialized and new “little giant” enterprise Recently, the Ministry of Industry and Information Technology officially announced the list of the sixth batch of national-level specialized and new “little giant” enterprises. Shenzhen TST CABLES Technology Co., Ltd. (hereinafter referred to as “TST CABLES”) has been honored to be on the list for its outstanding achievements in technological innovation, market performance and industry influence. It was awarded the honorary title of national-level specialized and new “little giant” enterprise. This honor is not only a recognition of TST CABLES’s long-term unremitting efforts and outstanding achievements, but also an important milestone in the company’s development history. It also indicates that the company’s technological innovation,

Customized cables: First principles simulation and calculation of cable material properties

Do you know what thinking methods are used by the world’s top technical engineers to study and calculate cable materials? TST cables will reveal the answer to you immediately. First principles calculation is a theoretical calculation method that predicts the properties of materials based on the principles of quantum mechanics. This method does not rely on any empirical parameters, but starts from the basic laws of physics and calculates the electronic structure and other properties of materials by solving the Schrödinger equation. In the study of cable materials, first principles calculation can be used to predict and optimize the performance of cable materials, including conductivity, thermal stability, mechanical strength and other aspects. First principles detailed explanationFirst principles (First Principles Thinking)

TST CABLES simulated railway cable vibration test system is online

Behind the high-speed trains and subways running at high speed, there is a group of cable technology experts who silently guard the power safety of the trains. They use the latest generation of high-speed rail vibration test equipment and systems of Railway cable supplier TST CABLES to ensure that every high-speed rail equipment cable can run smoothly and safely under rigorous testing. TST CABLES vibration test equipment uses advanced sensor technology to monitor the subtle vibrations of trains at high speeds in real time. Through high-precision test data collection, the equipment can capture any potential unstable factors of the cable. The system can quickly identify the key points that may cause cable failures and generate detailed analysis reports in real time. Through

Related by TST:

How to choose lszh cable railway cable subway fireproof soft cable

Subway fireproof soft cable is a cable designed to meet...

Read MoreDenmark cable Power Cable Denmark High Voltage Cable Solutions

As a Nordic country, Denmark enjoys a high reputation in...

Read More-200℃-+1200℃ Low smoke halogen free flame retardant PEEK cable Aircraft Cable

PEEK cable has super strong mechanical properties, good toughness and...

Read MoreApplication of low smoke zero halogen flame retardant cable(LSOH cable)in EMU

When the EMU shuttles across the vast land, it is...

Read MoreAlso available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese

Portuguese (Brazil)