The 15th China International Aviation and Aerospace Exhibition (hereinafter referred to as China Airshow) was successfully concluded in Zhuhai from November 12 to 17, 2024.

Zhuhai Airshow (China International Aviation and Aerospace Exhibition) is one of the largest aviation and aerospace exhibitions in China. It is held every two years and attracts aviation and aerospace companies, scientific research institutions and professional audiences from all over the world. At such a high-standard exhibition, cables, as key electrical connection components, play an important role in many aspects.

Zhuhai Airshow is not only an important platform for displaying aerospace technology, but also an important display window for cables and related technologies. From the internal wiring of aircraft and drones to the power and communication connections of ground support equipment, to the display and exchange of new technologies, special cables play an indispensable role in the Zhuhai Airshow.

Next, TST CABLES will explain the relevant characteristics and applications of some high-end special cables (PEEK cables, PI cables, PE cables) at the Zhuhai Airshow.

Aviation Cable Technology Innovation and Application

New Cable Technology: Zhuhai Airshow is also a platform for displaying the latest cable technology and products. Exhibitors may display new lightweight cables, high temperature resistant cables, smart cables, etc. to attract potential customers and partners.

New material applications: New insulation materials and sheath materials, such as PEEK, PI, silicone rubber, etc., will also be displayed and promoted at the air show.

- Aerospace aircraft cable application

Aircraft and helicopters: Modern aircraft and helicopters are full of various cables, including power cables, signal cables, data transmission cables, etc. These cables need to have the characteristics of lightweight, high temperature resistance, vibration resistance and high reliability.

UAVs: With the development of UAV technology, the demand for low-altitude aircraft cables is also increasing. These cables need to be lightweight, highly flexible, temperature resistant and have good electromagnetic compatibility.

Satellites and spacecraft: The cables used in satellites and spacecraft need to be able to work in extreme environments, such as high temperature, low temperature, vacuum and radiation environments. These cables are usually made of high-performance materials, such as PEEK, PI, etc. - Ground support equipment cable application

Power supply system: A large number of temporary power supply facilities are required at the air show site, including power generation vehicles, UPS systems, etc. The connection between these devices requires the use of high-quality power cables to ensure a stable power supply.

Communication system: The communication system at the air show site requires reliable cable connections, including fiber optic cables, coaxial cables, etc., to ensure the stability and security of data transmission.

Comparison of PEEK cable (polyetheretherketone) PI cable (polyimide) PE cable (polyethylene)

When selecting cables for low-altitude aircraft (such as drones, small helicopters, etc.), many factors need to be considered, including lightweight, temperature resistance, flexibility, mechanical strength and electromagnetic compatibility. PEEK (polyetheretherketone), PI (polyimide) and PE (polyethylene) are several common cable materials, each of which has its specific application scenarios and advantages. TST CABLES will take you to learn about the characteristics and applications of these three materials.

- PEEK (polyetheretherketone) cable

Features:

High temperature resistance: PEEK material has extremely high temperature resistance and can be used for a long time at a high temperature of 260°C, and can withstand temperatures up to 300°C in the short term.

Mechanical strength: PEEK has excellent mechanical strength and tensile strength and can withstand large mechanical stress.

Chemical corrosion resistance: PEEK has good resistance to most chemicals and is suitable for harsh environments.

Low smoke and halogen-free: PEEK materials produce less smoke and low toxicity when burning, which meets modern environmental protection and safety standards.

Electrical properties: It has high dielectric strength and volume resistivity, suitable for high voltage applications.

Applications:

Aerospace: used for cable connections in aircraft, satellites and other aerospace equipment.

Industrial automation: Industrial control systems used in high temperature, high pressure and corrosive environments.

Medical equipment: used for power and signal transmission in medical devices, especially in occasions where high temperature sterilization is required.

- PI (polyimide) cable

Features:

High temperature resistance: PI material has excellent high temperature resistance and can be used in a temperature range of -269°C to 400°C.

Mechanical strength: PI has good mechanical strength and tensile strength, and can withstand repeated bending and vibration.

Chemical corrosion resistance: PI has good resistance to most chemicals and is suitable for corrosive environments such as chemical and petroleum.

Electrical properties: It has high dielectric strength and volume resistivity, suitable for high voltage applications.

Lightweight: PI material has a lower density, which helps to reduce the overall weight of the cable.

Application:

Aerospace: Used for cable connections in aircraft, satellites and other aerospace equipment.

Industrial control: Industrial control systems used in high temperature, high pressure and corrosive environments.

Medical equipment: Used for power and signal transmission in medical devices, especially in situations where high temperature sterilization is required.

Electronic equipment: Used for internal wiring in high-performance electronic equipment, such as computers, servers, etc.

- PE (Polyethylene) Cable

Features:

Cost-effectiveness: PE material has a relatively low cost and is suitable for large-scale production and wide application.

Insulation performance: It has good electrical insulation performance and is suitable for medium and low voltage power transmission.

Flexibility: PE material is soft and easy to install and wire.

Water resistance: PE material has good water resistance and is suitable for humid environments.

Low temperature performance: PE material still maintains good flexibility and mechanical properties at low temperatures.

Application:

Power transmission: Used for medium and low voltage power transmission lines, such as household electricity, commercial buildings, etc.

Communication: Used for communication cables, such as telephone lines, data lines, etc.

Industrial control: control cables used in general industrial environments.

Agriculture: cable connections used in agricultural irrigation systems.

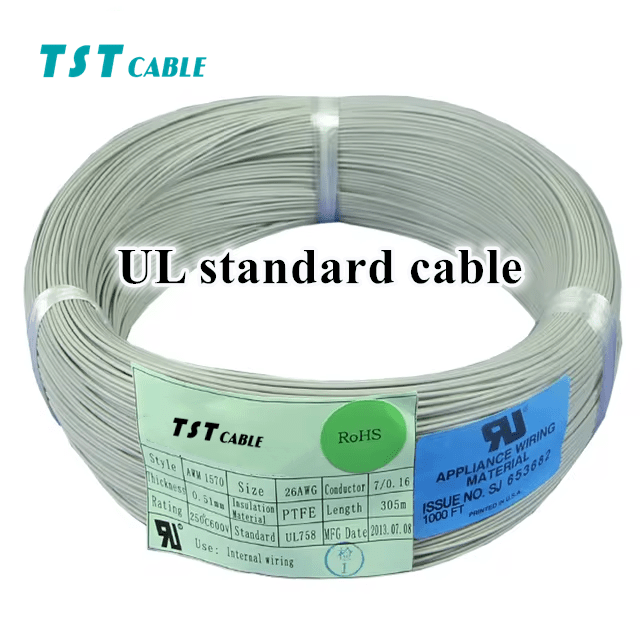

TST CABLES custom PEEK cables, PI cables, PE cables

PEEK cables: suitable for applications with extreme high temperatures, high mechanical strength and chemical corrosion resistance requirements, such as aerospace, industrial automation and medical equipment.

PI cables: suitable for applications with high temperature, high mechanical strength and chemical corrosion resistance requirements, such as aerospace, industrial control and medical equipment.

PE cables: suitable for cost-effective, medium and low voltage power transmission and general communication applications, such as household electricity, commercial buildings and agricultural irrigation.

Choosing the right cable material depends on the specific application requirements, including factors such as operating temperature range, mechanical stress, chemical environment, electrical performance and cost. For low-altitude aircraft, PEEK and PI cables are more popular due to their excellent temperature resistance and mechanical properties, while PE cables are suitable for some cost-sensitive applications with less demanding performance requirements. If you need custom PEEK cables, PI cables, PE cables, please send us an email to communicate your needs in detail and get free samples.

Also available in:

Arabic

English

Japanese

Russian

Portuguese (Brazil)