Cable and pipe transit systems for transport and cargo ships are essential to ensure the safe and reliable operation of the ship. These systems must not only be able to effectively manage the layout of cables and pipes, but also have fireproof, waterproof and explosion-proof properties to meet the various challenges of the offshore operating environment. TST CABLES will take you to learn about some key cable and pipe transit systems suitable for transport and cargo ships.

Cable transit system

1. Fireproof plugging system:

Fireproof materials (such as fireproof mud, fireproof board or intumescent sealant) are used to fill the holes through which the cable passes to prevent the spread of flames and smoke.

These systems need to comply with the standards of the International Maritime Organization (IMO) and other relevant agencies.

2. Waterproof seals:

Designed to prevent water from entering the cabin or equipment area, usually using seals or gaskets made of rubber or other elastic materials.

It is particularly important to protect electrical equipment from seawater erosion.

3. Anti-vibration design: Considering that ships may encounter vibrations when sailing in rough seas, the transit system should be able to withstand certain mechanical stresses without failure. The use of shock-absorbing brackets or flexible connections can reduce the impact of vibration on cables.

4. EMC/EMI shielding: For sensitive electronic equipment, electromagnetic compatibility (EMC) and electromagnetic interference (EMI) issues must be considered, and appropriate shielding measures must be adopted to protect the quality of signal transmission.

5. Easy maintenance: The design of the transit system should be easy to disassemble and reinstall for daily inspection and maintenance work.

Pipeline transit system

1. Pressure balancing device: Pipes passing between different air pressure zones may need to be equipped with pressure balancing valves to ensure safe operation and avoid problems caused by pressure differences.

2. Thermal insulation treatment: For pipelines transporting high-temperature media (such as steam), effective thermal insulation treatment is required to reduce heat loss and protect surrounding structures from thermal damage.

3. Corrosion protection: The high salt content in the marine environment is prone to metal corrosion. Therefore, the outer surface of the pipeline should be coated with an anti-corrosion coating or made of corrosion-resistant alloy.

4. Quick connection and disconnection mechanism:

In order to facilitate loading and unloading of cargo or emergency response, certain types of pipelines should have the ability to connect and disconnect quickly.

5. Monitoring and alarm:

Installing leak detection sensors and alarm systems can immediately notify the crew when a leak occurs, so that quick action can be taken.

Comprehensive considerations

Regulatory compliance: All cable and pipe penetration systems must comply with the regulations of relevant agencies such as the International Maritime Organization (IMO), the United States Coast Guard (USCG), and Lloyd’s Register (LR).

Environmental adaptability: Considering the characteristics of the marine environment, the system must have good weather resistance and durability, and be able to work stably under extreme temperature and humidity conditions.

Cost-effectiveness: Choose a cost-effective solution while ensuring the economy and reliability of long-term use.

Customized service: Provide personalized design solutions based on specific ship types and uses to ensure optimal performance.

When selecting cable and pipe transits for transport and cargo ships, it is important to fully evaluate their functional requirements, safety standards, and economic benefits to ensure that the selected system meets both technical requirements and practical application conditions. If you have more detailed requirements or specific scenarios, please provide more background information and I will provide you with more targeted suggestions.

Technical details of waterproof pipe penetration system

1. Fire performance:

Fire blocking systems must pass rigorous testing and certification, such as testing according to IMO MSC.1/Circ.1329 guidelines.

Use intumescent sealants or fireproof modules that can expand and seal holes under high temperature conditions to prevent the spread of flames.

2. Waterproof and moisture-proof:

For cables and pipes passing through watertight bulkheads, specially designed watertight joints or flange connections should be used, and high-quality sealing materials should be used.

Regularly check the status of the seals and replace aging or damaged parts in time to maintain good waterproofing.

3. Mechanical strength:

The penetration device should have sufficient mechanical strength to resist vibration and impact caused by ship movement.

The use of reinforced structures such as metal frames or special supports can enhance the stability of the system.

4. Chemical corrosion resistance:

In environments where chemicals or other corrosive substances are present, corrosion-resistant materials (such as stainless steel, glass fiber reinforced plastics, etc.) are selected to manufacture penetration components.

Surface treatment technologies such as galvanizing and coating with anti-corrosion coatings can also effectively extend the service life.

5. Electrical insulation:

For high-voltage cables, ensure that there is sufficient electrical insulation distance at the penetration point and use suitable insulating materials.

Insulating sleeves or sheaths are installed to protect the cables from physical damage and environmental factors.

Material selection for waterproof pipe penetration system

Metallic materials: For applications requiring high strength and good conductivity, copper, aluminum and their alloys can be selected.

Non-metallic materials: Where lightweight and corrosion resistance are required, composite materials, thermoplastics or rubber products can be considered.

Fireproof materials: Expanded fireproof coatings, ceramic fiberboards, asbestos substitutes, etc. are all common fireproof material options.

Sealing materials: Silicone sealants, polyurethane foams, EPDM rubber, etc. all have excellent sealing properties.

Best Practices for Waterproof Pipe Transit Installation and Maintenance

1. Professional Installation Team:

Trained professionals follow the manufacturer’s instruction manual to ensure that each step is in compliance with specifications.

2. Follow Manufacturer Recommendations:

Strictly follow the manufacturer’s installation guidelines, especially when dealing with critical functions such as fire protection and waterproofing.

3. Regular Inspection and Maintenance:

Establish a regular inspection system, especially for transits that are exposed or in harsh environments.

Record the results of each inspection and track the development trend of potential problems so that preventive measures can be taken in advance.

4. Emergency Response Plan:

Develop a detailed emergency plan, including how to quickly repair damaged transits to deal with emergencies.

5. Document Management:

Maintain complete installation records and technical documents to facilitate subsequent maintenance work and troubleshooting.

6. Training and Education:

Provide regular knowledge and skills training to crew members so that they understand the importance of transits and the correct use of them.

Special application scenarios of waterproof pipe penetration system

Liquefied natural gas (LNG) carriers: This type of ship has extremely high requirements for safety, so its penetration system must be able to withstand low temperature environments and strictly comply with the International Gas Safety Standard (IGC Code).

Chemical tankers: According to the characteristics of different types of chemicals, choose the corresponding protection level and materials to prevent leakage accidents.

Case study and experience sharing of waterproof pipe penetration system

Successful case analysis: By analyzing the problems encountered in past projects and their solutions, valuable lessons learned are summarized.

Industry exchange platform: Participate in industry associations and technical forums to share experiences and latest research results with other professionals.

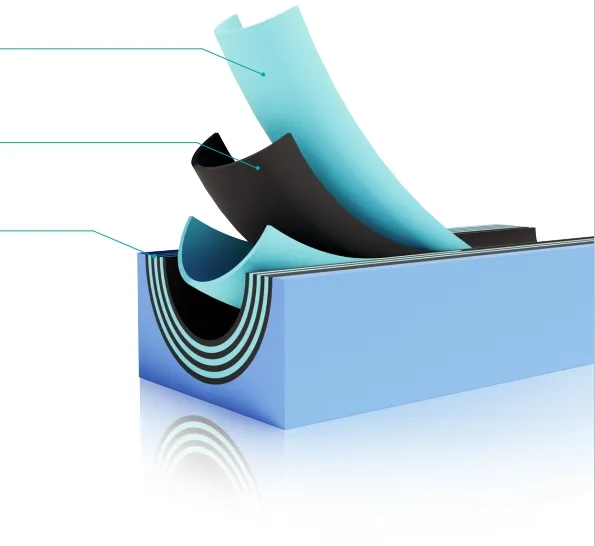

TST CABLES is a world-renowned manufacturer of cable penetration seals (MCT for short). MCT products are a modular sealing system. Using sealing modules with adjustable core layers, frames and clamping devices to form an intrusion-proof cable and pipe penetration sealing system. The flexibility of the modules and the mechanized system have the characteristics of simple and fast installation, easy expansion and reconfiguration, and global certification.

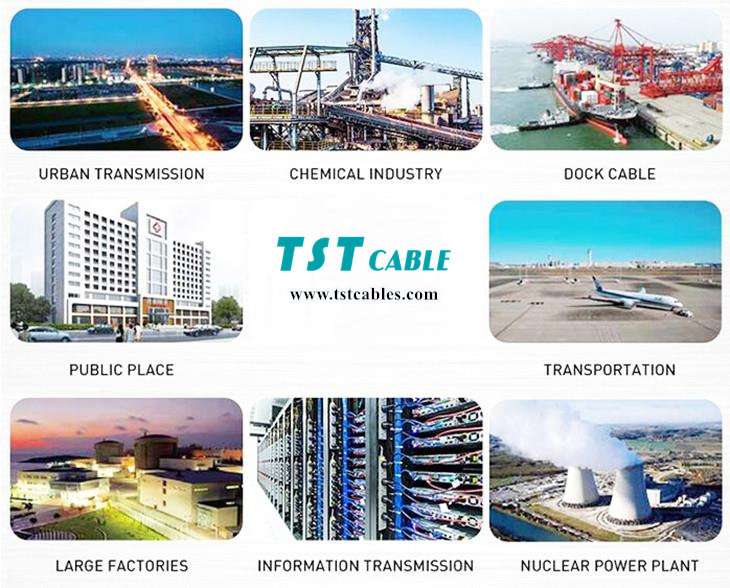

TST CABLES wall sealing systems are mainly used in: offshore platforms, oil and gas refineries, floating loading and unloading vessels, nuclear power plants, shipbuilding plants, computers/banks, communications, data centers, jet engine installations, defense industries, tunnel systems (trains, subways, etc.), water purification/drinking water treatment plants, chemical plants, pharmaceutical plants, offshore accommodation, etc.

Selecting appropriate cable and pipe penetration systems for transport ships and cargo ships involves many considerations, from material science to engineering practice, to later management and maintenance. By combining the above technologies and strategies, a safe and efficient ship infrastructure can be built to ensure the safety and efficiency of maritime transportation. If you have specific application scenarios or more detailed requirements, please feel free to send an email to communicate with TST CABLES engineers, and we will provide you with more targeted support and suggestions.

Also available in:

English