Why do most household and commercial cables follow the UL 758 standard? What industries are suitable for UL758 cables? TST CABLES will share and summarize with you.

What is the UL 758 cable standard?

The UL 758 cable standard is a technical document developed by UL (Underwriters Laboratories Inc.) to regulate the design, production and testing of appliance wiring materials (AWM). This standard covers a variety of conductors and cables and is applicable to soft wire assemblies used in household appliances, commercial equipment, and lighting fixtures.

Scope of application of UL 758 cable:

The UL 758 cable standard applies to appliance wiring materials with a rated voltage not exceeding 600V.

These materials are used to connect internal components of appliances or as connecting wires between appliances and power sources.

UL 758 cable material types:

Single insulated conductor.

Multi-conductor cable.

Optical fiber.

Independently insulated conductor.

Optical fiber is used as a component of multi-core cable assemblies.

UL 758 Cable Standard Conductor Specifications:

Conductor Material: The conductor material covered by the UL 758 standard is usually copper, and sometimes tinned copper or silver-copper alloy is also used. The conductor can be solid or stranded.

Conductor Size: The cross-sectional area of the conductor ranges widely, from very small conductors (such as 50 AWG) to larger conductors (such as 2000 kcmil). AWG (American Wire Gauge) is a standard for measuring the diameter of the conductor, while kcmil is another commonly used unit, especially in the case of large-sized conductors.

UL 758 Cable Standard Insulation Material:

Insulation Material Classification: The UL 758 standard divides insulation materials into two categories: thermoplastic and thermosetting.

Thermoplastic insulation materials: mainly include PVC (polyvinyl chloride), TPU (thermoplastic polyurethane), TPE (thermoplastic elastomer), etc.

Thermosetting insulation materials: usually refers to materials such as silicone rubber, which have better heat resistance and chemical resistance.

Insulation layer thickness: The minimum thickness of the insulation layer depends on the size of the conductor and the type of insulation material. For example, for smaller conductors, the insulation layer may be relatively thin, while for larger size conductors, thicker insulation layer is required to provide better protection.

UL 758 Cable Standard Jacket Material:

Jacket Material: Jacket material is usually PVC or other polymer materials to provide additional protection to the cable against abrasion and chemical damage.

Jacket Thickness: The minimum thickness of the jacket is also clearly specified to ensure the overall strength and durability of the cable.

UL 758 Cable Connectors and Terminals:

Connector Type: The connectors covered by the UL 758 standard can be in various forms, such as plugs, sockets, screw terminals, etc.

Terminal Material: The terminal material is usually metal, such as copper, nickel-plated steel, etc., to ensure good conductivity and mechanical strength.

Installation Requirements: The installation of connectors and terminals must be firm and reliable to avoid looseness or poor contact.

UL 758 Cable Performance Requirements:

Conductor sizes range from 50AWG to 2000kcmil.

The minimum operating temperature is 60°C (140°F).

The voltage rating is at least 30 volts.

Insulation materials are divided into two types: thermoplastic and thermoset.

Special types of conductors and cables, which may not need to meet all the requirements of general AWM.

UL 758 cable structure division:

UL 758 divides the types of electrical wiring into 5 parts:

Single-core conductor, thermoplastic insulation.

Multi-core conductor, thermoplastic insulation.

Single-core conductor, thermoset insulation.

Multi-core conductor, thermoset insulation.

Special types of single-core and multi-core conductors.

UL 758 cable test methods:

Bend test: Evaluate the durability of the cable when it is repeatedly bent.

Tensile test: Measure the bond strength between the conductor and the insulation layer.

Heat resistance test: Ensure that the cable can still maintain its performance at high temperatures.

Flame retardant test: Evaluate the performance of the cable under burning conditions.

Chemical resistance test: Test the stability of the cable when exposed to different chemicals.

Horizontal and vertical burning test of wires: Carried out in accordance with the requirements of the UL 758 standard to ensure that the cable has good flame retardant properties.

UL 758 Cable Marking and Labeling:

All AWMs need to be clearly marked with manufacturer information, product model, rated voltage and current, etc.

The labels must be durable and readable even under harsh conditions.

UL 758 Cable Standard Certification Process:

Initial Evaluation: The product is submitted to UL for evaluation for the first time.

Production Supervision: UL will conduct regular factory inspections on manufacturers to ensure production consistency and quality control.

Market Supervision: After the product is on the market, UL will also randomly select samples in the market for testing to ensure continued compliance with the UL 758 standard.

UL 758 Cable Example Products:

UL1007 Electronic Wire: This is a single-core conductor with PVC insulation layer, widely used in internal wiring of electronic equipment.

UL 2517 2x22AWG Electronic Jacketed Wire: This is a two-core cable, each conductor is 22AWG tinned copper wire with PVC jacket, used for signal transmission in electronic equipment.

UL 758 cable safety features:

Flame retardancy: The UL 758 standard requires cables to have certain flame retardant properties to reduce the risk of fire.

Heat resistance: The cable needs to be able to maintain its performance in high temperature environments to ensure safe use under extreme conditions.

Chemical resistance: The cable must be able to resist the effects of common chemicals to extend its service life.

Scope of application of UL 758 cable:

Cables covered by the UL 758 standard are widely used in various household appliances, commercial equipment and lighting fixtures. The following are some typical application scenarios of UL 758 cables:

Household appliance cables:

Washing machines, dryers, refrigerators, freezers, microwave ovens, ovens, vacuum cleaners, TVs, audio systems, air conditioners, fans, lighting fixtures.

Commercial equipment cables:

Office equipment: printers, copiers, scanners.

Catering equipment: coffee machines, blenders, toasters.

Kitchen equipment: refrigerators, freezers, ovens.

Cleaning equipment: vacuum cleaners, cleaning machines.

Lighting fixtures:

Indoor lighting: chandeliers, wall lamps, table lamps. Outdoor lighting: street lamps, landscape lamps. LED lighting systems, emergency lighting systems, etc.

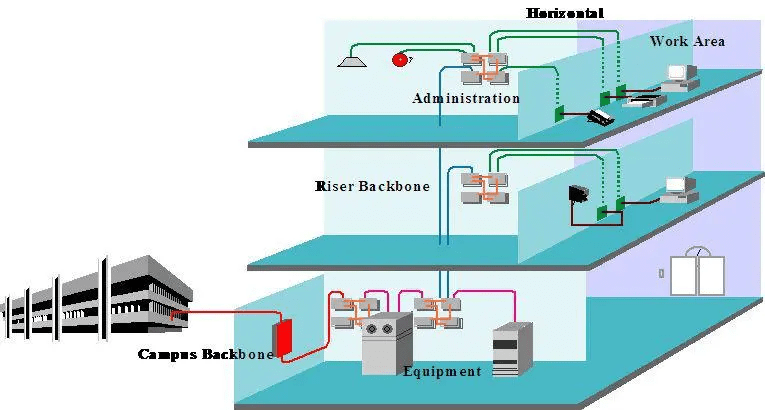

Telecommunications and data transmission:

Internal wiring of telecommunications units and electrical modules, wiring of telecommunications facilities, signal and power transmission in data centers.

Safety grounding cables:

Safety grounding cables in high-voltage facilities, maintenance of railway high-voltage overhead lines, safety grounding of electronic power supply companies, potential equalization of machines and IT systems, etc.

Power control cables:

Power, control and connection cables in power facilities; used for lossless data and signal transmission; fixed laying and mobile applications; suitable for dry, damp and wet rooms.

Special applications, high-voltage cables:

Safety grounding cables in high-voltage facilities, for maintenance of railway high-voltage overhead lines, and for grounding of live parts of high-voltage facilities.

UL 758 cable market applications:

Global recognition: The UL 758 standard is widely recognized worldwide, ensuring that the product can be exported to many countries and regions.

Industry standards: Many manufacturers use it as a benchmark for the production of soft wire assemblies.

Future development of UL 758 cables:

New materials: With the development of new materials, higher performance insulation and sheath materials may appear in the future.

Environmental requirements: In the future, the use of environmentally friendly materials, such as low-smoke halogen-free cables and low-smoke halogen-free flame-retardant cables, may be strengthened to reduce the impact on the environment.

Technological progress: With the advancement of technology, testing methods and certification procedures may become more stringent and comprehensive.

The implementation of the UL 758 cable standard ensures the safety and reliability of electrical wiring materials, which is essential for the safety of home appliances and commercial equipment. Every custom cable manufacturer needs to comply with these UL standards (UL 758, UL1581, etc.) during the design and production process to ensure that the products meet the prescribed quality levels and provide consumers with safe and reliable electrical products.

Cooperate with cable manufacturer TST CABLES to customize UL 758 cables

In the pursuit of excellence, every UL 758 cable is a reflection of our commitment to quality. From sophisticated conductor design to high-standard insulation materials, every detail embodies our unremitting pursuit of safety. The UL 758 standard ensures the excellent performance and reliability of cables in various application scenarios, making every connection a safe start.

Our cables not only meet the strict safety standards of UL 758, but are also the guardians of your home and business safety. Whether it is home appliances or commercial equipment, UL 758 cables can provide you with stable and reliable power transmission, allowing you to enjoy a worry-free living and working environment.

Cooperating with TST CABLES to customize UL 758 cables, let us join forces, collaborate and win together, and create a more stable, safe and efficient future.

Also available in:

Arabic

English

German

Indonesian

Japanese

Russian

Spanish

Thai

Vietnamese

Portuguese (Brazil)