There is a growing trend towards the use of low smoke zero halogen (LSZH) cables, which use jacketing materials that are safer in the event of fire. As the name implies, unlike traditional materials such as polyvinyl chloride (PVC) and fluorinated ethylene propylene rubber (FEP), low smoke zero halogen cables produce less dense smoke and almost no highly toxic gases called halogens.

Given this, it seems very reasonable that designers should always choose to use such cables, but the decision is far more complicated, so it is crucial for electrical engineers to understand LSZH cables, the scenarios in which they are suitable, and how to select and apply them.

Low Smoke Zero Halogen Cable (LSZH cable or LSHF cable, LSOH cable) is very suitable for environments with strict requirements on safety and environmental friendliness, such as laboratories and data centers. This type of cable can not only reduce the generation of toxic smoke in the event of a fire, but also avoid the release of corrosive halogen gases, thereby protecting the health of personnel and the safety of equipment, and meeting strict environmental standards. TST CABLES will take you to understand some key points of the application of low smoke zero halogen cables in laboratories and data centers.

Actual application scenarios of low smoke zero halogen cables in data centers

Application of low smoke zero halogen cables in laboratories:

In scientific research laboratories, due to the presence of a large number of sensitive experimental equipment and valuable instruments, choosing LSZH cables can effectively reduce the damage caused by fire to these assets and ensure the safety of researchers.

Application of low smoke zero halogen cables in data centers:

There are a large number of servers and other IT hardware inside the data center. Once a fire occurs, traditional halogen-containing cables will release a large amount of harmful gases, seriously threatening the safety of employees and the integrity of data, causing significant commercial damage and endangering the lives of staff. Therefore, the use of LSZH cables is one of the important measures to ensure the reliable operation of data centers.

LSZH cables are not suitable for all applications

It is important to remember that although cables using halogenated compounds such as PVC and FEP have been found to be hazardous in the event of fire, LSZH cables are not a universal solution to replace them for the following reasons. First, cables based on PVC and FEP also have important advantages that cannot be ignored, and there is not much advantage to using LSZH cables to replace them in open spaces where smoke and gases can spread quickly. Furthermore, cables are usually not the only source of plastic in a fire, and cables based on PVC and FEP are fire resistant, so they are less responsible for the fire, among other factors.

PVC and FEP-based cables are less expensive than LSZH cables, offer excellent electrical performance, are used in a wide range of applications, and have good electrical properties in both dry and wet environments. They are also highly flexible, have a long service life, can withstand extreme temperatures and chemicals, and are very rugged. In short, LSZH cables are best suited for situations where traditional cables might be hazardous. They are not intended to replace traditional cables in all applications.

The Rise of LSZH Cables

The burning and flame characteristics of PVC and FEP in cable jackets, dielectric materials, and other components have been known since the 1970s, and by around 1980, cables with alternative materials were already being used in military and nuclear systems. But in 1987, the fire at London’s King’s Cross subway station killed more than 30 people and injured more than 100, attracting widespread global attention (Figure 1).

Figure 1: Investigations into the King’s Cross fire at London’s King’s Cross Underground Station revealed that the burning of large amounts of electrical cables produced dense black smoke and toxic gases, making it difficult for people to escape. (Image source: Wikipedia)

Subsequent investigations revealed that a match dropped on an elevator was the cause of the fire, which spread and killed many people for a number of reasons. One of these reasons was the burning of large amounts of electrical cables, which produced dense black smoke and toxic gases, making it difficult for people to escape. This fire is thought to have prompted the development of cables that perform better and are safer in fires.

As a result of this incident, PVC cables were banned on the London Underground, and other EU members soon followed suit. It took longer for the United States to adopt these cables for a number of reasons, including cost considerations, conflicting standards, and debates about where they should be used. These issues have since been resolved, and PVC- and FEP-based materials are being replaced in applications where the benefits are most apparent.

The difference in LSZH cables

As opposed to PVC jackets, LSZH cables use jacket materials made of thermoplastic materials that do not generate halogens or caustic acids, produce little or no smoke, and significantly reduce flame spread, all of which make it easier to escape from a fire and reduce the dangerous work of firefighters. LSZH compounds are usually based on polyolefins and doped with hydrated minerals, which only produce less dense white smoke.

Over the years since LSZH cables were introduced, other compounds have been introduced with better results while maintaining the necessary electrical properties of the cables. Polymer materials that do not have flame retardant ingredients on their own are doped with additives such as inorganic hydrates (aluminum hydroxide or magnesium hydroxide) to optimize flame retardant properties. This heavy doping usually reduces some physical properties, so the cable industry has developed various methods to reduce or eliminate their effects using different compounds.

Confusing requirements

For designers, the situation remains very complicated because people have different opinions on the scenarios in which these cables should be used. There is no single standard or set of standards that designers can rely on to make an informed decision, and it is difficult to accurately distinguish LSZH cables from different manufacturers. The confusion is evident in the many acronyms that have been used over the years to describe cables that have some superior performance in fire.

FRLS Fire Resistant, Low Smoke

FRNC Flame Retardant, Non-Corrosive

HFFR Halogen Free, Flame Retardant

LC Low Corrosive

LH Low Halogen

LS Low Smoke

LSF Low Smoke

LSHF Low Smoke, Halogen Free

LSNH Low Smoke, Halogen Free

Table 1: Confusion due to lack of uniformity: some “fire resistant” cable nomenclature (Source: Anixter, Inc. Wikipedia entry)

As another example, the U.S. Department of Defense was one of the first to define halogen content in the MIL-C-24643 standard, which defined “low” halogen as less than 0.2% by weight. Other standards specify the amount of acid gas generated but do not specifically define the halogen level.

The main concern regarding cables used in ceiling compartments is that they can produce toxic and corrosive materials that can spread throughout a building. The National Electrical Code (NEC) requires cables used in ceiling compartment spaces to be “low smoke” rated, but this has been controversial because ceiling compartments typically have low combustible loads and are rarely exposed to ignition sources. The National Fire Protection Association (NFPA) is responsible for developing the NFPA 262 standard to address cables used in ceiling compartment spaces.

Fortunately, Underwriters Laboratories (UL) began developing low smoke and halogen-free ratings in 2015 and now offers halogen-free (HF) and LSZH cable certification programs based on the IEC 62821 and IEC 60754 series of standards. The IEC 62821 standard specifies requirements for halogen-free, low smoke, thermoplastic insulated and jacketed cables rated up to 750 volts. UL’s HF and LZSH marks can be used on many types of cables, from appliance cables to communications cables (including fiber optics), flexible cords, and tray cables for power and control.

All UL-certified HF and LSZH cables also meet other UL general certification requirements. UL has also expanded its component recognition program under UL 2885 to include halogen evaluations. This should help manufacturers of insulation and jacket compounds and other cable components, including filler cords, tapes, and wrapping tapes.

Where LSZH makes a difference

Deciding whether to use LSZH can be difficult, especially for the inquiring designer who digs into the various standards and building codes and the many documents that cover the issues. Fortunately, the need for the protection provided by LSZH cables is usually quite obvious. Generally speaking, LSZH cables should be considered in the following scenarios: large numbers of cables are installed in close proximity in a confined space, evacuation routes are limited, ventilation is poor, and high voltages are present.

Good examples of applications where LSZH cables were first used include fires on surface ships and submarines, where escape is difficult or sometimes impossible, and nuclear facilities, where smoke, toxic materials, and corrosive gases can have catastrophic consequences.

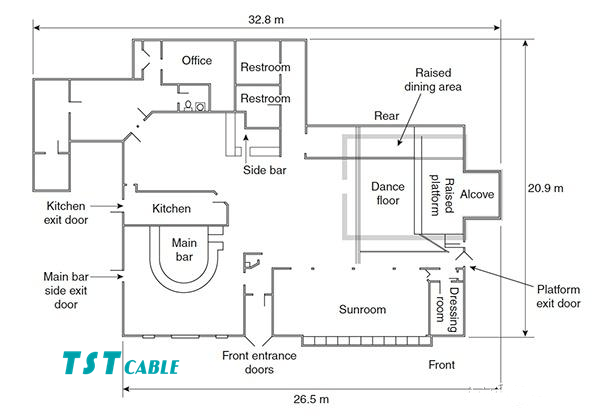

Other applications include commercial aircraft, transportation terminals, certain areas of airports, telecommunications switching centers, tunnels, theaters, and nightclubs (Figure 2). The model below shows the “Station” nightclub in West Warwick, Rhode Island, which was engulfed in a fire in 2003, killing 100 people and injuring another 230.

Figure 2: This model of the “Station” nightclub shows that while there are some evacuation routes, there are also locations that are difficult to escape from, especially if hundreds of people are in a panic. (Image source: National Institute of Standards and Technology)

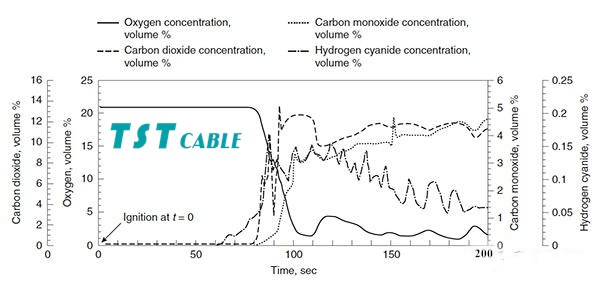

While there are some evacuation routes, there are also locations that are difficult to escape from, especially if hundreds of people are in a panic. Time to the exit is critical because toxic fumes can build up quickly, as measured in the model below (Figure 3).

Figure 3: Gas concentrations in the center of a nightclub between the kitchen and dance floor during the first 200 seconds after fire ignition (t = 0). The probe was placed 1.5 meters above the ground. (Image credit: National Institute of Standards and Technology)

The latest applications for the use of LSZH cables include the growing number of data centers. Data centers are densely packed with cables and have extensive cooling infrastructure where flames and smoke can spread quickly. It may be surprising that LSZH cables are not now universally required in data centers, even though their use is becoming more common.

In fact, there are several factors that can support or refute the use of LSZH cables. In new construction, one of the most important considerations is the amount of combustible load supported by the building materials, which requires knowledge of the materials used and an assessment of the overall environment. Unfortunately, this is often difficult to do in existing buildings because knowledge of the materials used in the building is difficult or even impossible to obtain.

Performance and Cost

In the past, LSZH cables had lower electrical and mechanical performance than conventional cables, but that has changed dramatically. Cable manufacturers continue to optimize the performance of LSZH cables, which offer flame-retardant properties of PVC and FEP materials without sacrificing flexibility, bend radius, low-temperature tolerance, and electrical performance.

Prices for LSZH cables are still generally higher because they require more steps and manufacturing time to produce. However, as the U.S. market for LSZH cables expands, their cost may decrease. LSZH cables have historically been poorly suited for cold-weather applications because additives often reduce the flexibility of the cable, especially at very low temperatures. However, some of the latest LSZH cables use proprietary technology to alleviate this problem.

Choosing the Right LSZH Cable

With all the rules, specifications, and different regulations and standards in place, it can be difficult for cable manufacturers to fully determine whether they are truly LSZH rated. Some data sheets appear to meet these requirements, but curiously, they often do not explicitly state this and only provide information about the cable construction (primarily the jacket), often ignoring the dielectric material.

A good example of a data sheet that explicitly states LSZH attributes is the multi-core cable family from Alpha Wire, which includes the 1172L SL005 two-core cable all the way up to the 6017L SL005 24-core cable (Figure 4). The data sheets for these products clearly state that the products achieve LSZH ratings and the tests they pass, including the IEC 60332-1 standard for flammability, the EC 60754-1 and 60754-2 standards for acid gas generation, and the IEC 61034-2 standard for smoke emissions.

Figure 4: The data sheets for the 1172L SL005 two-core cable (left) and the 6017L SL005 24-core cable clearly state that the products achieve LSZH ratings and the tests they pass, rather than being vague. (Image credit: Alpha Wire)

Some other manufacturers also describe LSZH properties, but others bury this information somewhere in the data sheet, which may change if more engineers ask for these properties. If you are interested in purchasing a cable and the manufacturer does not clearly state the product’s fire properties, your best bet is to contact the manufacturer. The company may also be able to produce a custom version with some or all of the excellent fire properties. LSZH cables from multiple manufacturers should be compared to select candidates with excellent fire performance, and then their flexibility, temperature range, bend radius, service life and other key indicators should be compared. The final selection should have excellent fire performance and little functional difference from PVC cable.

Summary

What we can learn from this article is that although LSZH cables have been around for decades, their use is only just beginning to accelerate. There is no alliance or organization actively promoting LSZH cables, and there is little agreement on the scenarios in which LSZH cables should be used or even how cable manufacturers should describe them on their websites or in data sheets. Fortunately, the situation is now improving, thanks to UL’s decision to add LSZH and LSF to its certification testing program. Hopefully, this momentum continues, rather than waiting for another serious fire incident to take action.

In the meantime, designers and electrical engineers can either choose an off-the-shelf LSZH cable or specify the standards that the LSZH cable must meet for custom applications as needed.

Related reading:

If you are interested in the application of low-smoke halogen-free cables in laboratory data centers, please check out another article:

13 reasons why large laboratory data centers use low-smoke halogen-free cables

Also available in:

English