Under the background of “dual carbon”, my country’s energy transformation is accelerating. As an important part of clean energy, hydropower plays an irreplaceable and important role in the construction of clean, low-carbon, safe, efficient, flexible and intelligent new energy system and new power system.

As the core component of the hydropower station, the cabinet system is responsible for the distribution, protection and control of electric energy to ensure the normal operation of the power system. However, cabinets face many challenges in hydropower stations, including insufficient sealing performance, extreme environmental conditions, and complex internal wiring. These problems can cause equipment failure and distortion of monitoring data, affecting the working performance of the equipment and the power generation efficiency of the hydropower station.

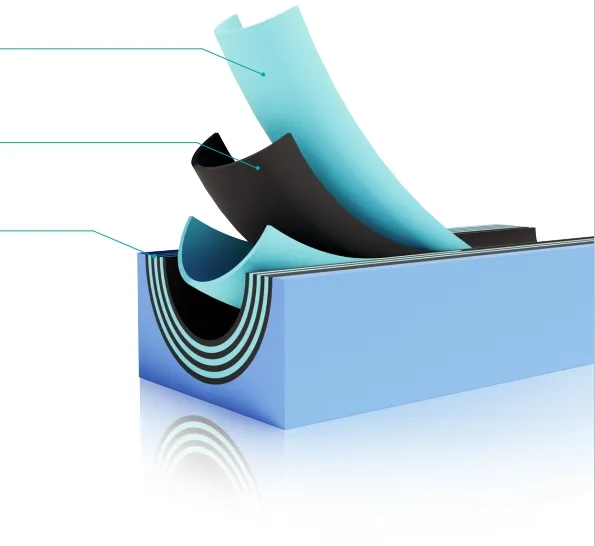

In order to meet these challenges, modular plugging technology has been widely used. This technology improves the plugging effect through modularization and standardization of plugging components, facilitates installation and maintenance, extends the service life of equipment, and reduces maintenance costs, providing strong technical support for the safe, efficient and intelligent operation of hydropower stations.

Let’s take a look at how TST CABLES’ modular plugging system is used in the Jinsha River Basin Hydropower Station~

(Note: Due to customer privacy requirements, the article refers to the Jinsha River Basin Power Station or the power station)

(Real photos of the power station control cabinet)

As the largest single-unit capacity hydropower station under construction in the world, the power station is located in the lower reaches of the Jinsha River. Its important position and huge scale have attracted much attention in the global hydropower field. During the operation of the power station unit, the cabinets are often affected by natural factors such as wind, rain, and dust; the unit vibrates during operation, causing the equipment connectors in the cabinet to loosen, affecting the normal operation of the equipment.

In order to solve the many problems faced by the cabinets in actual operation, the power station chose TST CABLES modular cable and pipe penetration sealing system to plug the cabinets.

Electrical box plugging construction drawing

Application effect

- Improve the sealing performance of the cabinet, prevent moisture and dust from invading, and ensure the normal operation of the equipment.

The modular cable and pipe penetration sealing system effectively improves the sealing performance of the cabinet through its tight structure and high-performance sealing materials, and can effectively prevent moisture and dust from invading the interior of the cabinet, avoid damage to the equipment, and ensure the normal operation of the equipment. In the complex environment of the hydropower station, the modular sealing system can effectively resist the influence of natural factors such as wind, rain, sand and dust, and provide a safe and stable operating environment for the equipment in the cabinet.

- Alleviate the impact of unit vibration, prevent the loosening of equipment connectors in the cabinet, and protect precision instruments and sensors.

The unit of the hydropower station will vibrate during operation, which may cause the loosening of equipment connectors in the cabinet and affect the normal operation of the equipment. The modular sealing system can alleviate the impact of unit vibration, reduce the transmission of vibration through its special design and materials, protect the precision instruments and sensors in the cabinet, ensure the accuracy of monitoring data, and improve the working performance of the equipment.

- Resist external extreme environment, enhance the corrosion resistance and anti-aging performance of the cabinet, and extend the service life.

The environment of the hydropower station is relatively extreme, facing challenges such as high temperature, low temperature, corrosion and condensation. The modular sealing system uses polymer materials, has good corrosion resistance and anti-aging properties, and can resist the influence of extreme external environments. Enhance the durability of the cabinet, extend its service life, and reduce maintenance costs.

- Optimize internal wiring, reduce the difficulty of maintenance, reduce the frequency of shutdown maintenance, and improve power generation efficiency.

The modular design of the sealing system helps to optimize the internal wiring of the cabinet, making the cable laying more standardized and orderly. During maintenance, the modular components are easy to disassemble quickly, convenient for inspection and maintenance, and reduce the difficulty of maintenance. Reducing the frequency of shutdown maintenance caused by equipment failure improves the power generation efficiency of the hydropower station and provides strong support for stabilizing the power grid.

In short, the perfect combination of the modular cable and pipe penetration sealing system and the power station provides a strong guarantee for the safe and stable operation of the power station.

The successful application of the modular cable and pipe penetration sealing system in the cabinet of the power station provides new ideas and methods for the construction of large-scale power stations in my country. TST CABLES Technology focuses on providing domestic brands of modular cable and pipe penetration sealing systems for users in various industries. It will continue to strengthen the research and development of sealing systems, improve their performance and reliability, and provide more powerful technical support for the safe construction of power stations in my country.

Also available in:

English