What is the conversion between AWG and the metric system? TST CABLES introduces various cable technology formulas in detail.Utilize this Standard Wire Gauge Conversion Chart to easily convert AWG (American Wire Gauge) wire sizes to inches and millimeters in the laboratory.

What is the AWG wire means?

AWG (American Wire Gauge), also known as Brown/Sharpe wire gauge, has been used as a standard wire gauge in the United States since 1857. It is widely used to measure the diameter of cylinders, cubes, non-ferrous metals and power control lines. Its cross-sectional area determines the current carrying capacity of the conductor.

AWG (American Wire Gauge) is the American wire standard used to describe the diameter of the wire, while the metric system usually uses the cross-sectional area (usually square millimeters, mm²) to describe the size of the wire. The conversion between AWG and metric is not a direct linear relationship, but is based on the logarithmic relationship of the wire diameter.

AWG to Metric (mm²) Conversion Formula

There is no simple linear formula for the conversion between AWG and mm², but it can be approximated by the following steps:

Conversions in Real-World Applications

In real-world applications, it is common to use a lookup table to convert between AWG and mm² because it is more accurate. For example, 18 AWG wire is approximately 1.02 mm², while 16 AWG wire is approximately 1.31 mm².

Notes

· These formulas and conversions are only for round wire.

· Different wire materials, such as copper and aluminum, may have different conversion constants.

· Actual wire sizes may vary from manufacturer to manufacturer, so it is best to refer to the datasheet of the specific wire manufacturer.

Example

If you want to convert from AWG to mm², you can use the formula above or look up the metric cross-sectional area that corresponds to the AWG value. For example, for 24 AWG copper wire, its cross-sectional area is approximately 0.208 mm² (the actual value may vary slightly depending on the specific standard).

In summary, the conversion between AWG and mm² involves complex mathematical relationships, but in real-world applications, using a lookup table is the simplest and most accurate way.

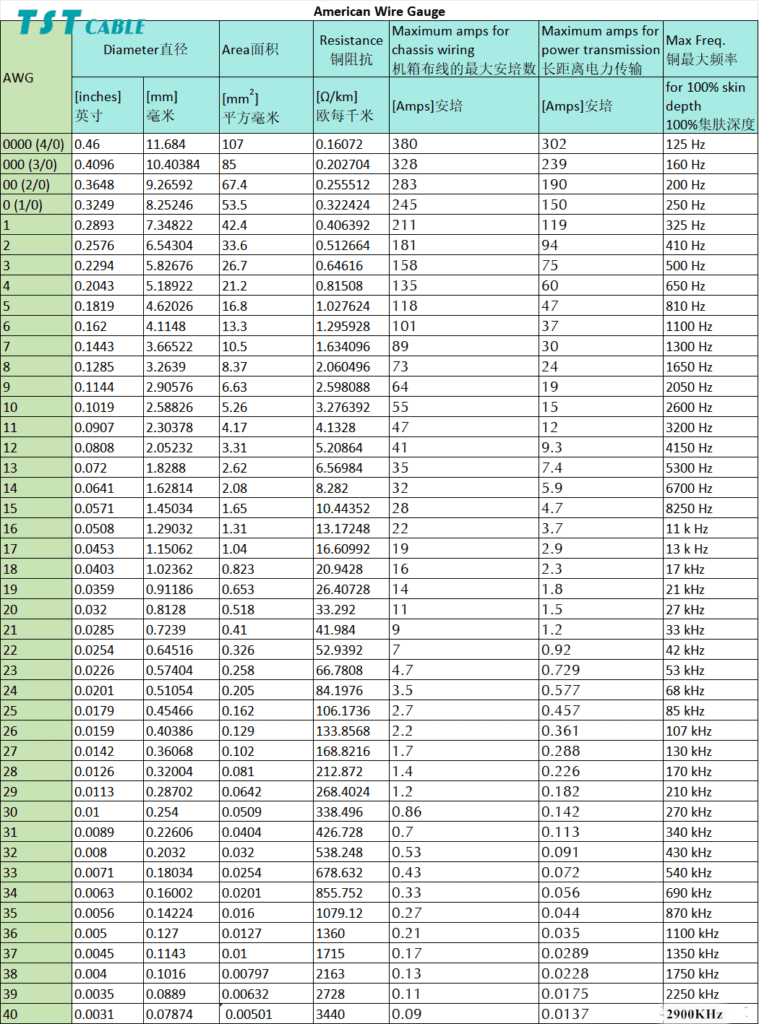

The most common way to express conductor size is to use the cross-sectional area, expressed in mm². The following AWG Metric Conversion Table converts AWG to mm and inches and lists the cross-sectional area in mm².

AWG Metric Conversion Chart (AWG to mm)

| American Wire Gauge (AWG) | Diameter (in) | Diameter (mm) | Cross sectional area (mm2) |

| 0000 (4/0) | 0.460 | 11.7 | 107.0 |

| 000 (3/0) | 0.410 | 10.4 | 85.0 |

| 00 (2/0) | 0.365 | 9.27 | 67.4 |

| 0 (1/0) | 0.325 | 8.25 | 53.5 |

| 1 | 0.289 | 7.35 | 42.4 |

| 2 | 0.258 | 6.54 | 33.6 |

| 3 | 0.229 | 5.83 | 26.7 |

| 4 | 0.204 | 5.19 | 21.1 |

| 5 | 0.182 | 4.62 | 16.8 |

| 6 | 0.162 | 4.11 | 13.3 |

| 7 | 0.144 | 3.67 | 10.6 |

| 8 | 0.129 | 3.26 | 8.36 |

| 9 | 0.114 | 2.91 | 6.63 |

| 10 | 0.102 | 2.59 | 5.26 |

| 11 | 0.0.907 | 2.30 | 4.17 |

| 12 | 0.0808 | 2.05 | 3.31 |

| 13 | 0.0720 | 1.83 | 2.63 |

| 14 | 0.0641 | 1.63 | 2.08 |

| 15 | 0.0571 | 1.45 | 1.65 |

| 16 | 0.0508 | 1.29 | 1.31 |

| 17 | 0.0453 | 1.15 | 1.04 |

| 18 | 0.0403 | 1.02 | 0.82 |

| 19 | 0.0359 | 0.91 | 0.65 |

| 20 | 0.0320 | 0.81 | 0.52 |

| 21 | 0.0285 | 0.72 | 0.41 |

| 22 | 0.0254 | 0.65 | 0.33 |

| 23 | 0.0226 | 0.57 | 0.26 |

| 24 | 0.0201 | 0.51 | 0.20 |

| 25 | 0.0179 | 0.45 | 0.16 |

| 26 | 0.0159 | 0.40 | 0.13 |

If this AWG metric calculator doesn’t provide you with the information you need, please get in touch with the technical experts of TST cables who will be pleased to answer your questions or calculate the appropriate AWG/metric size for your installation.

AWG to Metric (mm²) Conversion

The AWG standard was originally based on an assumption that the diameter of a “0000” (or 4/0) AWG wire is 0.46 inches, and that the diameter decreases by a fixed ratio for each additional AWG number. This ratio is approximately 92 raised to the power of 1/39, since the diameter decreases by approximately half for every 6 AWG numbers.

Diameter Calculation

First, we can calculate the diameter (in inches) of any AWG number using the following formula:

Dinches=0.005×92(36−N)/39

Where N is the AWG number and Dinches is the wire diameter in inches.

Cross-sectional area

Once we have the diameter, we can calculate the cross-sectional area. For round wire, the area calculation formula is as follows:

Ain2=π×(Dinches/2)2

Converting the area from square inches to square millimeters, we know that 1 square inch equals 645.16 square millimeters, so:

Amm2=Ain2×645.16

Lookup table method

Although the above formula provides a theoretical calculation method, in actual applications, it is often more practical to use a lookup table method. Here are some approximate values of cross-sectional area (mm²) corresponding to some common AWG numbers:

10 AWG ≈ 5.3 mm²

12 AWG ≈ 3.3 mm²

14 AWG ≈ 2.1 mm²

16 AWG ≈ 1.3 mm²

18 AWG ≈ 0.8 mm²

20 AWG ≈ 0.5 mm²

22 AWG ≈ 0.33 mm²

24 AWG ≈ 0.21 mm²

Notes

The values in the above table are approximate values, and the actual cross-sectional area may vary slightly depending on the manufacturer’s specific standards.

The actual cross-sectional area of the wire is also affected by the material, for example, copper and aluminum wires may have different cross-sectional areas even at the same AWG number.

Use scenarios

In electrical engineering and design, it is very important to understand the conversion of AWG to metric units, because it directly affects the calculation of current carrying capacity and voltage drop, as well as the selection and installation specifications of wires. For example, when selecting appropriate fuses and circuit breakers, the rated current carrying capacity of the wire is a key parameter, which is directly related to the cross-sectional area of the wire.

In summary, although the conversion between AWG and metric units involves some complex mathematical operations, in practical applications, the lookup table method is the most convenient and sufficiently accurate method. For more precise calculation needs, the above formula can be used for calculation, while also taking into account the specific data of the wire material and manufacturer.

If you have questions about the cable calculation formula or are not sure what specifications to use, you can contact TST CABLES technical experts via email.

Also available in:

English