1、Single-core mounting wire production process

Conductor→Insulation injection molding→Voltage resistance test→Qualified by inspection→Packed in rolls→Factory

Conductor → conductor stranded or bundled wire → insulation injection molding → pressure resistance test → qualified → roll packaging → factory

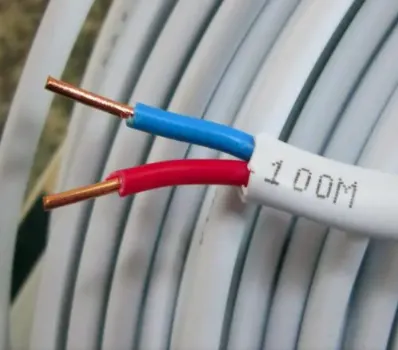

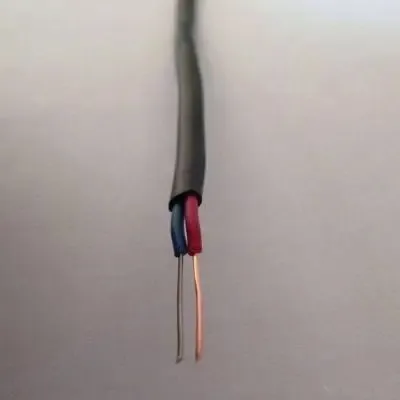

2、Sheathed installation line production process

Sheathed installation line

Conductor→Insulation injection molding→Pressure resistance test→Combined sheath injection molding→Qualified by inspection→Reel packing→Factory

Conductor → conductor stranded or bundled wire → insulation injection molding → pressure resistance test → combined sheath injection molding → qualified → roll packaging → factory

3、Special single-core installation line production process

Conductor→Insulation injection molding→Pressure resistance test→Qualified by inspection→Packed in rolls→Factory

Conductor → conductor stranded or bundled wire → insulation injection molding → pressure resistance test → qualified → roll packaging → factory

4、Special Sheathed Installation Wire production process

Conductor → high-temperature F46 injection molding or silicone rubber insulation → pressure test → combined sheath high-temperature F46 injection molding or silicone rubber → qualified → roll packaging → factory

Conductor → conductor stranded or bundled wire → high-temperature F46 injection molding or silicone rubber insulation → pressure test → high-temperature F46 injection molding or silicone rubber combined sheath → qualified → roll packaging → factory

5、Compensation wire or compensation cable production process

Conductor→Insulation injection molding→Pressure resistance test→Combined sheath injection molding→Qualified by inspection→Packing in rolls→Factory

Conductor→Insulation injection molding→Voltage resistance test→Combined shield braiding→Sheath injection molding→Qualified by inspection→Reel packing→Factory

Conductor → high-temperature F46 injection molding or silicone rubber insulation → pressure test → combined shielding braiding → high-temperature F46 injection molding or silicone rubber sheath → qualified → roll packaging → factory

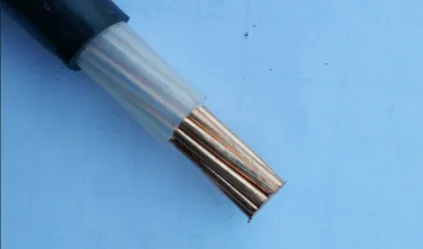

6、Power Cable production process

Conductor→Insulation injection molding→Pressure resistance test→Cable or steel armor→Sheath injection molding→Qualified by inspection→Packed in reels→Factory

Conductor→conductor stranding→insulation injection→pressure resistance test→cable or steel armor→sheath injection→qualified→tray packaging→factory

7、Special power cable production process

Conductor→high-temperature F46 injection molding or silicone rubber insulation→pressure-resistant test→cable or steel armor→sheath high-temperature F46 injection molding or silicone rubber→qualified→tray packing→factory

8、High voltage power cable production process

Conductor → high-voltage cross-linked three-layer co-extruded insulation injection molding → pressure test → cable or steel armor → sheath injection molding → qualified → tray packaging → factory

Conductor → conductor stranding → high-voltage cross-linked three-layer co-extruded insulation injection molding → pressure test → cable or steel armor → sheath injection molding → qualified → disk packaging → factory

9、Special Silicone Rubber High Voltage Cable production process

Conductor→conductor stranding→high-voltage silicone rubber insulation→pressure-resistant test→cable or steel armor→silicone rubber sheath→qualified→tray packaging→factory

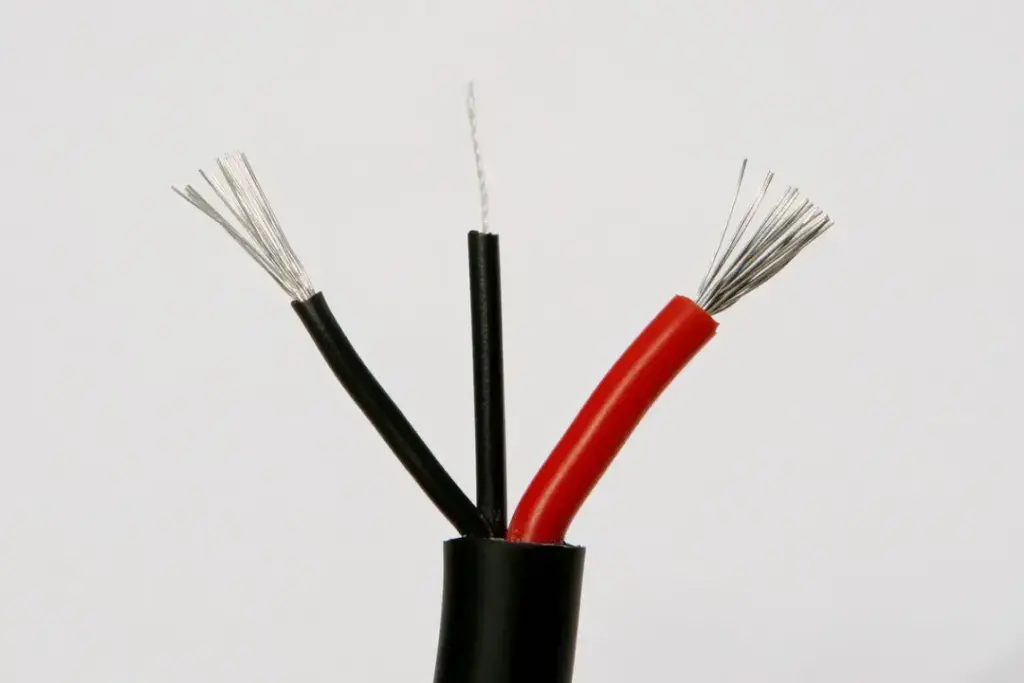

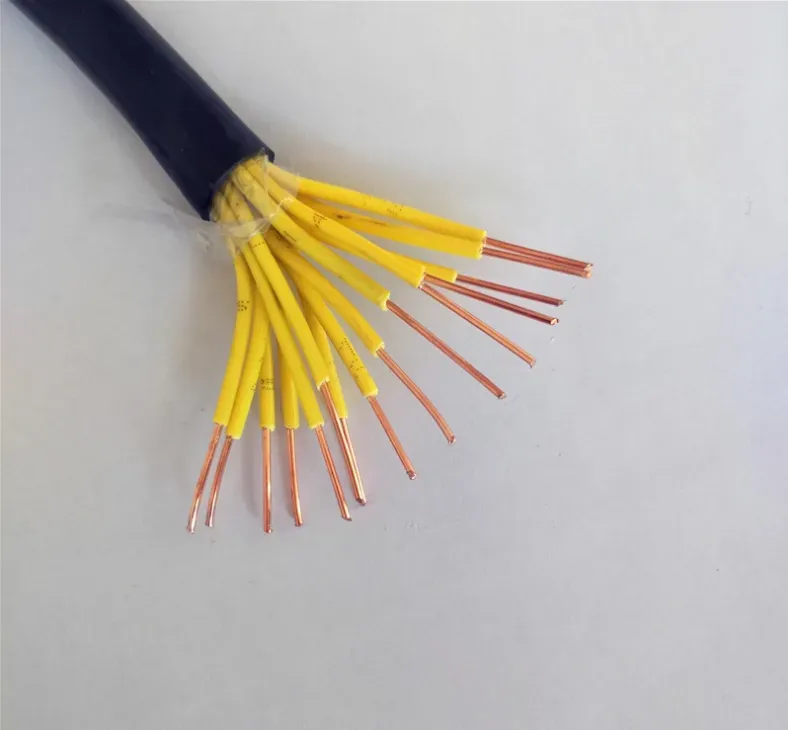

10、Control Cable production process

Conductor → insulation injection molding → pressure resistance test → cable or shielding → sheath injection molding → qualified → tray packaging → factory

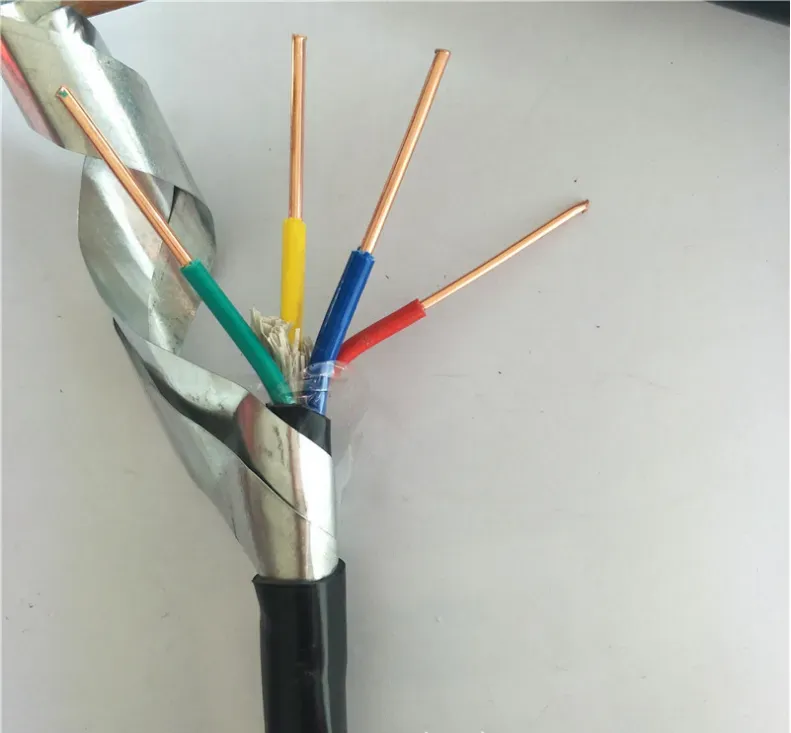

11、Special control cable production process

Conductor → high-temperature F46 injection molding or silicone rubber insulation → pressure resistance test → cable or shielding → sheath high-temperature F46 injection molding or silicone rubber → qualified → tray packaging → factory

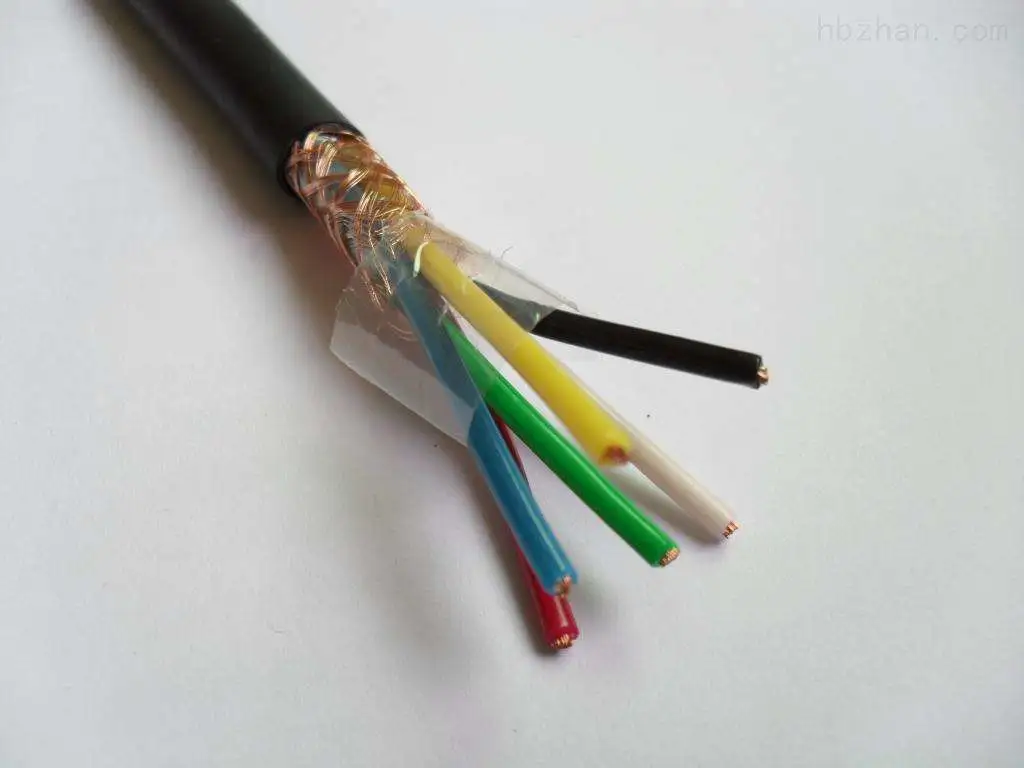

12、Computer Cable production process

Conductor→Insulation injection molding→Pressure resistance test→Pair stranding→Cable formation→Total shielding→Sheath injection molding→Qualified by inspection→Packing in trays→Exporting from factory

Conductor→Insulation injection→Pressure-resistant test→Pair stranding→Sub-shield→Cable forming→Total shield→Sheath injection→Qualified by inspection→Tray packing→Factory

13、Special computer cable production process

Conductor → high-temperature F46 injection molding or silicone rubber insulation → pressure resistance test → twisting → cable → total shielding → sheath high-temperature F46 injection molding or silicone rubber → qualified → tray packaging → factory

Conductor → high-temperature F46 injection molding or silicone rubber insulation → pressure test → twisted → sub-shielded → cable → total shielding → sheath high-temperature F46 injection molding or silicone rubber → qualified → tray packaging → factory

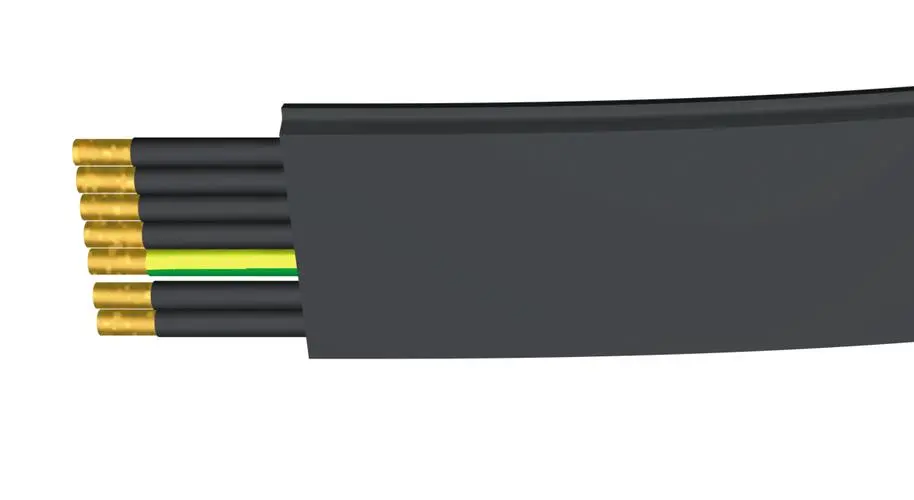

14、Flat cable (special) production process

PVC flat cable Conductor → conductor stranded or bundled wire → insulation injection molding → pressure test → combined sheath injection molding → qualified → disk packaging → factory

Butyl flat cable Conductor → conductor stranded wire or bundle wire → butyl insulation injection molding → pressure test → combined butyl sheath injection molding → qualified → disk packaging → factory

Silicone rubber flat cable Conductor → conductor stranded wire or bundle of wires → silicone rubber insulation → pressure test → combined silicone rubber sheath → qualified → disk packaging → factory

15、Magnesium oxide mineral insulated cable production process

Magnesium oxide mineral insulated cable (also known as: special fire-resistant cable), conductor with magnesium tube → filling → adding magnesium powder → head → compression → drawing → gas-protected continuous annealing → drawing (repeatedly) → gas-protected continuous annealing (repeatedly) → hydrostatic test → electric pressure test → or add the outer sheath → sealing → re-testing → packing → factory

Wire and cable used to transmit electrical (magnetic) energy, information and electromagnetic energy conversion wire products. Wires and cables in the broad sense of the term is also referred to as cable, cable in the narrow sense of the term refers to the insulated cable, which can be defined as: the following parts of the aggregate; one or more insulated cores, as well as their respective insulation may have a covering layer, the total protective layer and the outer layer, the cable can also be additional conductors are not insulated.

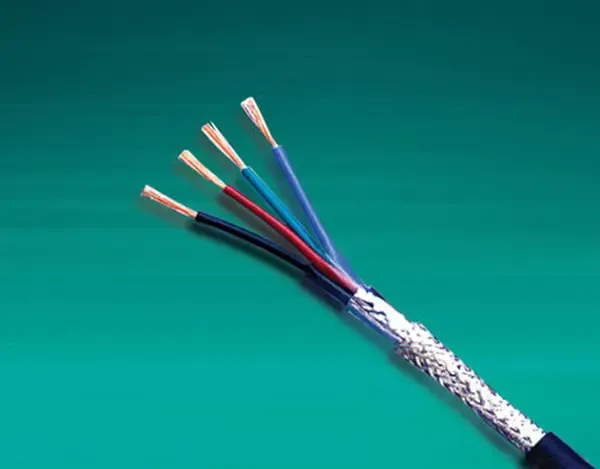

16、Frequency converter cable (special) production process

Conductor → insulation injection molding → pressure test → shielding → cable or steel armor → sheath injection molding → inspection and qualification → disk packaging → factory

Conductor→conductor stranding→insulation injection→pressure resistance test→shielding→cable or steel armor→sheath injection→qualified→tray packaging→factory

Also available in:

English