The key difference in cable quality: the quality of materials varies widely for the same cable.

Cables play a crucial role in industrial production for the transmission of power, data and communication signals. However, the same cables can have huge differences in quality. These differences are not only in terms of performance and durability, but also in terms of safety and environmental friendliness. Below TST CABLES will explain why the same cables vary so much in quality and how to recognize high quality cables.

- Material quality

One of the most significant differences between identical cables lies in the materials used. The materials used in the conductor, insulation and sheath of a cable all have a profound effect on its performance and longevity. High-quality cables often use pure copper conductors, while lower-quality cables may use aluminum conductors or copper-plated aluminum conductors, which not only transmit inefficiently, but also generate heat, which can be a safety concern. High-quality cables have clear writing and markings on them, including information such as model number, specification, voltage level and manufacturer. - Insulation

Insulation serves to isolate the conductors in a cable, preventing current leakage and faults. High-quality cables use durable insulation materials such as polyethylene (PE), polyether ether ketone (PEEK), polyimide (PI), or polyvinyl chloride (PVC), and the insulation layer is uniform in color and free of impurities. On the other hand, low-quality cables may use inferior insulating materials that are prone to aging and rupture, resulting in a much shorter cable life. - Sheathing materials

The sheath material of the cable is used to protect the cable from physical damage and environmental influences. High-quality cables are usually sheathed in durable materials such as polyvinyl chloride (PVC) or polyethylene (PE), which are resistant to UV rays, moisture and chemicals. Low-quality cables may use inferior sheath materials that break easily, leaving the cable vulnerable to damage. - Conductor quality:

The conductor core should be glossy, free of oxidation and oil.

Copper conductor should be purple-red, soft to the touch, tough; if the conductor is black, hard or impurities, it may be recycled copper or impurity copper made. - Bending performance:

Take a section of the cable for bending, if the bend feels soft and not easy to break, it is a good cable.

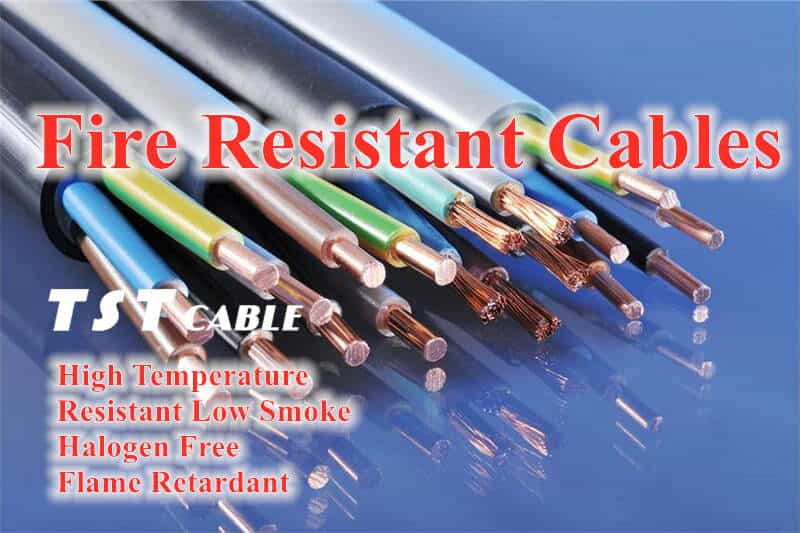

If it feels stiff or breaks easily when bending, it may be a poor quality cable. - Flame retardant properties:

High-quality cables usually have low-smoke, halogen-free flame retardancy, which can be verified by looking at the cable’s flame-retardant labeling or using an open-flame test. - Specifications and certifications

High-quality cables usually follow the specifications of international standards and certification bodies, such as UL, CE, CCC, ISO, etc. These certifications ensure that the cable will perform well and that it will not be damaged. These certifications ensure the performance and safety of the cable. Low-quality cables may not have relevant certifications, and their performance and safety are difficult to guarantee. - Measure conductor diameter and structure:

Use calipers or micrometers to measure the conductor diameter to ensure that it meets specifications.

Observe the structure of the conductor to make sure it is tight and free of gaps. - Smell:

Cut a small section of cable insulation and smell whether it has a pungent odor. High-quality cables should have no odor or only a slight odor. - Brand, price and reputation

Price is usually one of the indicators of cable quality. High-quality cables are usually more expensive because they use more expensive materials and advanced manufacturing techniques. Low-priced cables may be tempting, but they usually sacrifice quality to reduce costs. Reputation is also an important factor, and choosing a manufacturer with a good reputation can reduce the risk of low quality cables.

The difference in quality between identical cables can be significant. So when purchasing cables, consumers should focus on material quality, insulation, sheath materials, specifications and certifications, as well as the manufacturer’s reputation. High-quality cables not only perform more consistently and last longer, they are also safer, more reliable and more economical in the long run.

When purchasing, choose well-known brands and reputable manufacturers, such as TST CABLES These manufacturers usually have stricter quality control and after-sales service.

Observation and testing by combining the above aspects can help you identify high quality cables. Be sure to choose carefully when purchasing to ensure the safety and reliability of use.

Also available in:

English