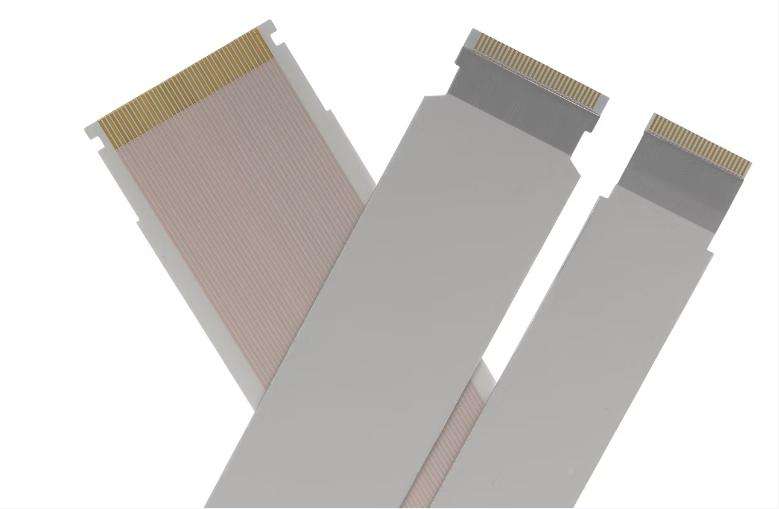

What is Flexible Flat Cable?

FFC Cable is the abbreviation of “Flexible Flat Cable”. It is a new type of data cable made of PET insulation material and extremely thin tinned flat copper wire, which is pressed together by high-tech automated equipment production line. FFC is a high-performance, flexible and easy-to-use data cable that plays an important role in modern electronic devices.

Application of Flexible Flat Cable FFC

Because flexible flat cables can be bent, they are widely used as space-saving wires. In recent years, various devices have become smaller, lighter, and space-saving, and flexible flat cables have also begun to be manufactured.

Flexible flat cables can also be used to connect printed circuit boards to circuit boards, or circuit boards to electronic components. It is relatively cheap and can be bent and used repeatedly, so it is often used where it is needed. Specifically, we sell all household appliances, LCD TVs, kerosene heaters, printers and copiers, stereos, video recorders, and telephones.

Flexible flat cables come in many variations, including multi-core cables, double-sided tape cables, halogen-free cables, and gold-plated cables.

Flexible flat cable FFC principle

It has a structure in which the top and bottom of the flat wire are sandwiched between plastic films used as insulators, adhesive is applied to the joint surface, and then the wire is crimped using heat and pressure. By crimping, the thickness of the flexible flat cable can be made extremely thin, such as about 0.3mm. Although tinned copper foil is mainly used for wires, nickel-plated copper and gold-plated copper are also used.

In addition, polyethylene terephthalate (PET) and polyimide are commonly used as plastic films used as insulators. As an adhesive, a polyester-based adhesive is used. The upper limit of the operating temperature of most cables is around 75°C, which is not very high, but there are also high heat-resistant flexible flat cables whose upper limit of the operating temperature is around 125°C, depending on the material.

The ends of the flexible flat cable are reinforced with a reinforcing plate made of polyester film or the like, and are formed so that they can be connected to the connector. The specific structures are: a structure in which both ends of the conductor are exposed and supported by the reinforcing plate; a structure in which the conductor is supported by the reinforcing plate so that the exposed side of the conductor is turned over; and a structure in which the conductor is supported by the reinforcing plate. The case where the conductor is supported by the reinforcing plate and exposed on the other side, and the case where the conductor is supported by the reinforcing plate only at one end. In addition, there are some products that improve the matching performance with the connector by designing the shape of the reinforcement plate.

The flexible flat cable is bonded to the reinforcement plate with hot melt adhesive. If used with a connector at high temperature (150°C), the adhesive may soften and the connection stability may become unstable. There are also reports that a polyester-based adhesive has been developed to solve this problem.

FFC cables have the following significant features:

Softness : FFC cables are very soft and can be bent and folded at will, which makes them flexible in various complex wiring environments.

Thin and light : FFC cables are thin and small in size, making them very suitable for internal connections of electronic devices with high space requirements.

Simple connection : The connection method of FFC cables is relatively simple, and it is easy to disassemble and reinstall, which greatly reduces the difficulty of maintenance and replacement.

Electromagnetic shielding : FFC cables also have the advantage of easy solution of electromagnetic shielding (EMI), which can effectively protect the circuits in the circuit board from external electromagnetic interference.

Wide application : FFC cables are widely used in electronic devices such as mobile phones and computers to connect circuit boards or components to transmit electrical signals.

Which is better, FFC cable or FPC cable?

FFC cable (Flexible Flat Cable) and FPC cable (Flexible Printed Circuit) are both types of flexible circuits. They have their own advantages and disadvantages and are suitable for different scenarios. Below TST CABLES will explain their differences in detail to help you better select cables:

Structure and Design:

FPC cables usually adopt a multi-layer structure, consisting of a flexible substrate and a circuit layer, which can achieve multi-layer circuit design and support higher integration and more complex circuit layout.

The FFC cable structure is relatively simple, generally consisting of a single layer of flexible substrate and conductive circuits, with a straight shape and usually only one layer of circuit.

Flexibility and Application:

FPC cables have good flexibility and plasticity, can be bent and folded, adapt to small space requirements, and are suitable for compact and highly integrated applications such as smartphones, wearable devices, etc.

FFC cables also have a certain degree of flexibility, but their bending degree and shape are not as flexible as FPC. It is suitable for scenarios where bending requirements are not high, and because of its low cost and high production efficiency, it is more suitable for large-scale production.

Performance and durability:

FPC cables have good performance in terms of high temperature resistance, vibration resistance, and aging resistance, and are suitable for products that require long-term high-intensity work or are used in harsh environments.

The durability and anti-interference ability of FFC cables are relatively weak, but they are sufficient for general household appliances and office equipment that are less exposed to extreme working conditions.

Width of flexible flat cable (FFC)

The width of a flexible flat cable (FFC) is actually determined by factors such as the number of conductors, spacing, and margins. However, what we usually call “cable width” more often refers to the distance between the two edges of the cable, that is, the total width (W).

In common specifications, the width of a flexible flat cable does not have a fixed standard value, but is customized according to different application needs and design requirements. Generally speaking, the width of the cable increases with the number of conductors, and the spacing and margin settings will also have a certain impact on the width.

TST CABLES’s common flexible flat cable spacing specifications are 0.25mm, 0.3mm, 0.4mm, 0.5mm, 0.8mm, 1.0mm, 1.25mm, 1.27mm, 1.5mm, 2.0mm, 2.54mm, etc. But please note that these are only the specifications of the spacing, not the direct values of the cable width. To get the actual width of the cable, you also need to consider other factors such as the number of conductors and the margin.

For example, if there is a flexible flat cable with a spacing of 1.0mm and 10 conductors, then its total width (excluding the margin) is at least 1.0mm multiplied by (10+1), which is 11.0mm. But in fact, since factors such as margins need to be considered, the actual cable width may be larger than this value.

In general, the width of the flexible flat cable is a relatively flexible concept, which will be customized according to different application needs and design requirements. If you need a specific width value, it is recommended to customize the cable according to your actual application scenario and factors such as the number of conductors, and consult a professional cable manufacturer or supplier for accurate size information.

Flexible flat cable (FFC cable and FPC cable) Cost and production efficiency:

The manufacturing process of FPC cable is relatively complex and the production cost is relatively high. It is suitable for electronic products with high performance requirements and complex designs.

The production process of FFC cable is relatively simple, mainly relying on the welding or crimping of single-layer circuits, with low production costs and high production efficiency. It is suitable for cost-sensitive and simpler products.

Flexible flat cable standards

Most flexible flat cables comply with UL standards. UL standards are product safety standards set by Underwriters Laboratories, Inc. (UL). Most flexible flat cables comply with UL standards. UL standards are product safety standards set by Underwriters Laboratories, Inc. (UL).

The display on the product itself is a mark indicating that it is a standard product that complies with UL standards. The UL standard of the product belongs to the AWM (Appliance Wiring Material) category. FFC products are manufactured to UL styles, and ratings (temperature, voltage) and flame retardant standards are determined for each UL style number. All FFC products pass flame retardant standards, the most stringent of which is the vertical flame retardant test (VW-1).

In addition, for certain applications, some products need to obtain CSA standards. CSA standards are Canadian safety standards for electrical appliances such as machine tools, electronic equipment, and medical equipment, and are formulated to protect human life and property safety.

Choosing FFC or FPC depends mainly on your specific needs. If your product requires high-density circuit connection, more functional integration, or complex circuit layout in a small space, FPC cable may be more suitable. If your product design is relatively simple, the circuit layout is not complicated, and you want to reduce costs and improve production efficiency, then FFC cable may be a better choice. TST CABLES flexible flat cable specifications are: 0.25mm-2.5mm, etc.; if you are not sure which type of cable is more suitable for your device, please email TST CABLES cable engineers to help you select and customize solutions, and you can also get free samples.

Also available in:

Arabic

English

Japanese

Russian

Portuguese (Brazil)